The ability to rapidly change and adapt is one of the hallmarks of the software industry, allowing it, through strong DevOps practices, to achieve an incredible pace of innovation without sacrificing on quality or robustness. By contrast, the process of designing and building physical products has traditionally been much slower, due unavoidable constraints such as building prototypes and running computationally expensive simulations. Now, however, artificial intelligence could offer a path to enabling the same level of rapid innovation for hardware designers that software engineers have long enjoyed.

In a recent podcast, guests Boris Scharinger, Senior Innovation Manager and Technology Strategist for Siemens Digital Industries, and Dr. Justin Hodges, Senior AI/ML Technical Specialist in Product Management for Siemens Digital Industries Software continued a conversation on how AI is redefining the product design process. AI offers new approaches to validating product designs, encoding information and supporting cross-pollination between teams which, in the future, will support a more rapid pace of innovation and broader scope of design space exploration.

The key to faster simulation

The industrial metaverse is shaping up to be an aggregation platform where thousands of digital twins come together to form a real, true-to-life simulation in a way that simply isn’t possible today, Boris explains. Currently though, simulations, and by extension digital twins, focus on individual components or elements of a system rather than the entire system itself, in no small part due to the cost of running high-fidelity simulations.

Simulation being a targeted tool applied in specific scenarios and with a limited scope makes sense given the cost in time, money and computational resources they require. However this also limits the ability for designers to explore a broad design space or optimize a design all the way to the end of the manufacturing process. But by intelligently leveraging AI it’s possible to accelerate these processes, leveraging ROMs (reduced order models) and AI-based models to work alongside existing simulation methods to reach proven results in a fraction the time.

AI models can offer nearly instant inferences on any and every part of the design process, allowing ideas to validated quickly and teams to check results and transfer information across disciplines in a way that simply isn’t possible using traditional methods, says Justin. Leveraging AI technology to foster a stronger connection between different teams and accelerate the flow of data will only be the first step in AI’s journey to reshape design space exploration though.

AI reimagines design space exploration

Returning to the idea of rapid innovation, when combining a safe-to-test and highly accurate digital twin with AI-powered fast simulations, hardware design can enjoy the same rapid iteration process as the software industry. With a risk-free virtual testing environment and high-precision, low-cost simulations available within the “industrial metaverse,” Boris states that companies can achieve DevOps for hardware. This enables hundreds or even thousands of design iterations to be tested within the same timeframe that traditional design processes would only allow for a few.

- DevOps for hardware has many exciting implications for improving both efficiency and sustainability in the product design process:

Instantly assessing the manufacturability of a design change before producing any physical prototypes. - Simulating the entire production workflow based on a digital design, allowing for virtual commissioning of manufacturing lines even during the product design phase.

- Rapidly optimizing machine configurations, component suppliers, and materials to minimize waste and improve sustainability in ways that traditional approaches cannot achieve.

All these advancements become possible thanks to AI, which significantly reduces the cost of slow and expensive design steps, enabling continuous optimization and rapid innovation. Compared to current design space exploration techniques, an AI-driven approach unlocks continuous optimization, offering greater flexibility in both design and manufacturing.

Smart applications of AI will be vital in reshaping the way companies approach design space exploration as well as making sure next generation products are designed and manufactured to meet the needs of tomorrow.

(Source: Siemens)

Read more:

- Smarter, Faster AI Chip Design with Siemens’ 3D IC Packaging Technology at ETRI and Amkor

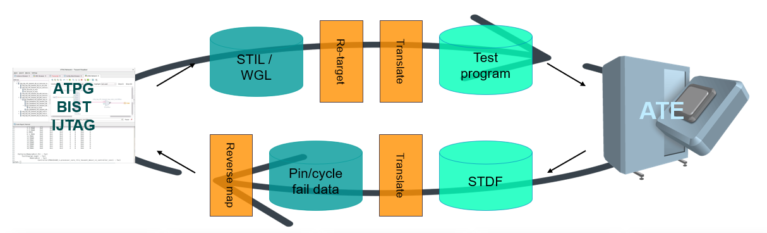

- How AI is accelerating semiconductor testing

- Leveraging the comprehensive digital twin for semiconductor