As a CAM programmer using advanced CAM software, not integrating Artificial Intelligence into CNC machining processes could be costing more than you realize—time, effort, and resources that could be better spent.

As industries undergo digital transformation, adopting new technologies is making part manufacturing smarter, faster, and more efficient. Artificial Intelligence (AI) plays a key role in this shift, and CAM software is no exception. In CNC machining, AI-driven processes are improving automation, precision, and integration with cloud-based solutions. In this blog, we’ll explore how AI is applied in CAM software and programming.

Here are some of the ways AI is making a significant impact in CAM software and programming, improving efficiency, precision, and automation in CNC machining:

1. Automated feature recognition

Feature recognition has long been one of the most valuable AI-driven features in CAM programming. Why? Because it saves an incredible amount of time.

What is AI feature recognition?

AI feature recognition uses machine learning to automatically detect and classify geometric features like holes, pockets, slots, and contours in a 3D model. The CAM system then suggests suitable toolpaths or machining strategies.

Key Benefits:

- Faster Programming: Minimizes manual feature selection and toolpath generation.

- Consistency and Accuracy: Reduces human error in identifying complex geometries.

- Knowledge Retention: Captures best practices and tribal knowledge for reuse.

- Scalability: Enables efficient CAM programming in high-mix/low-volume environments.

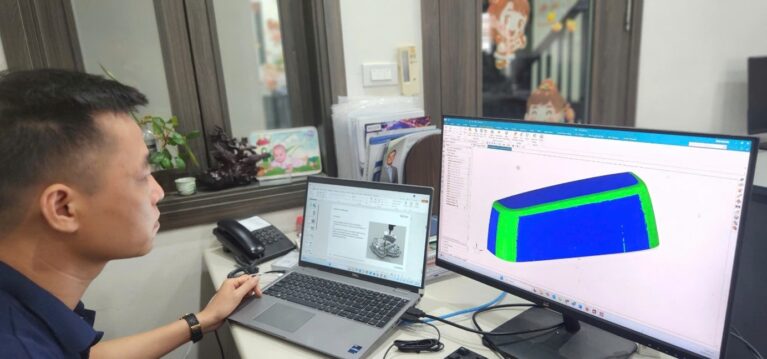

NX CAM in AI action

If you haven’t noticed, NX CAM has been delivering automation through Feature-Based Machining (FBM) for quite a while now. With FBM NX CAM automatically recognizes features and applies standard machining operations. It even suggests the best machining sequence—like roughing before finishing or choosing a mill-turn setup. The best part? It learns from your choices, remembers them, and reuses them in future jobs. This reduces manual setup and speeds up programming dramatically.

2. AI-powered assistants, copilots, and chat interfaces

CAM programmers often spend too much time defining machining strategies and tool parameters. What if AI could democratize CAM programming—reducing the learning curve from years to hours?

AI chat models and copilots embedded into CAM systems now make this possible. Stuck on which operation to choose? Ask your AI copilot. Want to generate NC code using a simple prompt? It’s now feasible. While these copilots still require programmer validation, they drastically reduce programming time and support decision-making.

Thumb rule remains: Always simulate before executing any NC code.

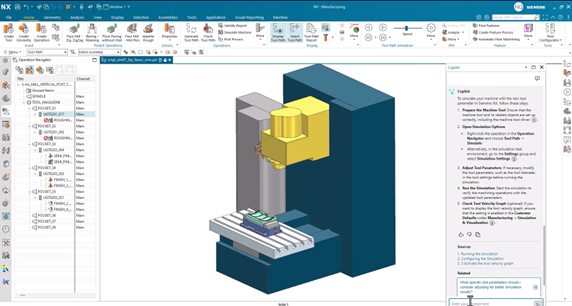

NX CAM in AI Action

The new NX X Manufacturing Copilot within NX CAM assists NC programmers with intelligent prompts, suggestions, and context-aware guidance. The copilot is used to assist NC programmers with navigating the NX software and to ask domain specific questions. This capability will save you time and make your shop more productive. From tool selection to programming strategies, the copilot helps reduce complexity. Imagine asking NX CAM, “How do I change the tool diameter?” and get immediate steps plus links to relevant documentation. It’s like having a smart assistant built into your CAM workflow.

Watch the below video to get a detailed demonstration of how you can use this latest NX X Manufacturing chat co-pilot.

3. AI-driven decision support

CAM programmers constantly make decisions on machining strategy, tooling, and parameters under pressure. These decisions need to be fast and accurate as they directly impact tool life, part quality, and cycle time.

With AI, these decisions are now supported by intelligent suggestions based on the part context—geometry, material, past toolpath decisions, and similar part programs.

Key Benefits:

- Predictive Edits: Suggests optimized operations when changes are made.

- Context-Aware Toolpaths: AI recommends strategies that suit part and material.

- Reusable Knowledge: Learns from prior jobs and improves consistency across programs.

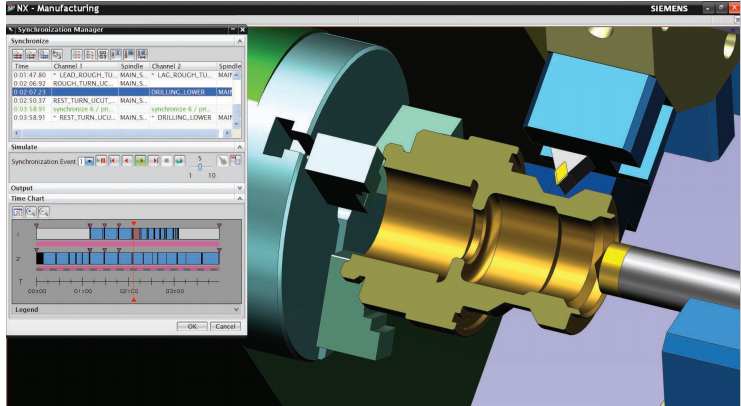

NX CAM in AI Action

NX CAM uses AI-assisted object editing to offer real-time suggestions when modifying toolpaths or machining parameters. Whether it’s adjusting feeds and speeds or replicating edits across similar parts, NX CAM’s AI learns from past patterns and helps programmers make confident, consistent decisions.

4. AI-powered plug-ins and software extensions

CNC programming can be a real bottleneck in manufacturing—time-consuming, prone to errors, and heavily reliant on skilled machinists who are in short supply. Traditional CAM systems often involve a lot of manual input for creating toolpaths, which not only slows things down but also introduces the risk of inconsistencies and delays.

This is where AI-powered plug-ins, like CloudNC’s CAM Assist, really shine. It takes the guesswork and manual effort out of toolpath generation by automating tasks like roughing, finishing, and adjusting feeds and speeds. And the best part? It works within your existing CAM software so there’s no need for a whole new setup.

Key Benefits:

- Speeds up programming from hours to minutes.

- Reduces dependency on expert programmers.

- Works within existing CAM systems like NX CAM.

NX CAM in AI Action

Siemens has partnered with CloudNC to integrate CAM Assist into NX CAM. This enables automatic creation of machining strategies for 3- and 3+2-axis machines, drastically accelerating toolpath generation. Users can now automate complex programming tasks while maintaining precision—saving time and increasing shopfloor productivity.

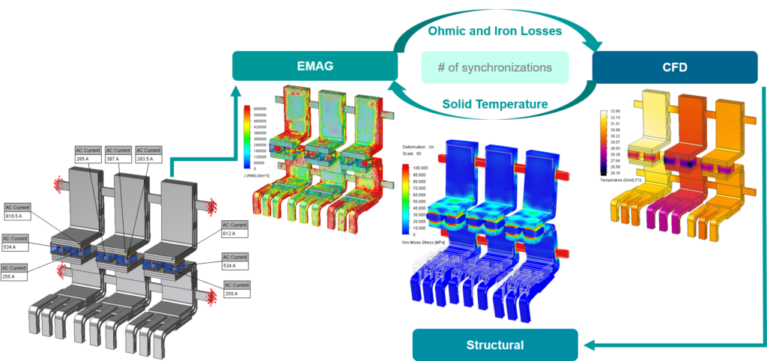

Another example of AI-powered software extensions is the integration of SenseNC into NX CAM. In collaboration with Productive Machines, a UK-based AI startup specializing in CNC optimization, this automated milling optimization software addresses issues like chatter vibrations, excessive tool wear, and tool breakages. It simulates toolpaths and adjusts cutting parameters to improve quality, extend tool life, and reduce cycle time. Using advanced physics and AI, it simulates countless machining permutations tailored to your machine, taking the guesswork out of milling and achieving optimized feed rates and spindle speeds across multi-toolpath operations.

Watch the video case study to see how AML, a metallic components manufacturer for aerospace, reduced costs and improved quality with NX CAM and SenseNC, achieving a 20% cycle time reduction.

5. In summary

AI is no longer a futuristic concept—it’s actively reshaping how CAM software operates. From automatic feature recognition to conversational copilots and real-time decision support, AI is making CNC programming faster, smarter, and more accessible.

And with NX CAM leading the way through integrated AI features, programmers can achieve higher productivity while reducing complexity—keeping up with the demands of modern part manufacturing.

(Source: Siemens)

Read more:

- Purpose-Built AI Machines: Farm-ING is revolutionizing Agriculture for a Sustainable Future

- AI-enabled design in NX

Contact us for free and detailed advice: