With increasing pressure to bring more innovative and smarter products to market quickly and at lower cost, manufacturers are striving to enhance the efficiency of engineering and manufacturing processes. This requires a solution that can describe, visualize, and validate production processes within a digital environment. Teamcenter Manufacturing is a manufacturing process management solution worth exploring and adopting for enterprises.

Teamcenter Manufacturing provides a collaborative environment within the enterprise to validate and optimize manufacturing plans and production engineering processes concurrently with product design. By enabling a common workspace for multiple functional departments, it significantly improves the iteration loop between engineering and manufacturing. This helps reduce waste and increase the value of production decisions, as information is utilized by more stakeholders to make better decisions in less time.

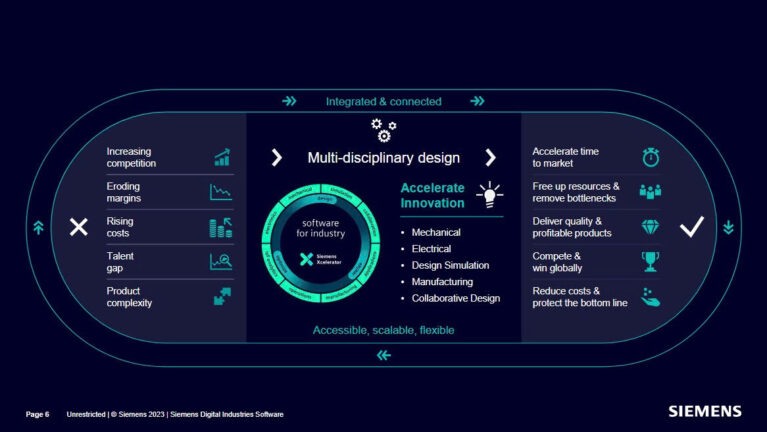

The challenge of disconnected stages in the product development and manufacturing process

The challenge of disconnected stages in the product development and manufacturing process

To address the challenges of cost and time-to-market, businesses must maximize the utilization of their existing resources. Searching for information, planning manufacturing processes, and handling continuous changes all negatively affect productivity. Teamcenter Manufacturing’s capability to manage manufacturing processes provides a consistent and up-to-date source of information that enhances individual productivity while facilitating task execution and process control. These solutions drive productivity through open integration with the enterprise’s existing IT infrastructure. The solution enables data management from concept design through product service, allowing data to be created or imported once and then reused across various departments for different purposes. Interconnected and inheritable data fosters reuse, helping minimize time and cost for resource execution.

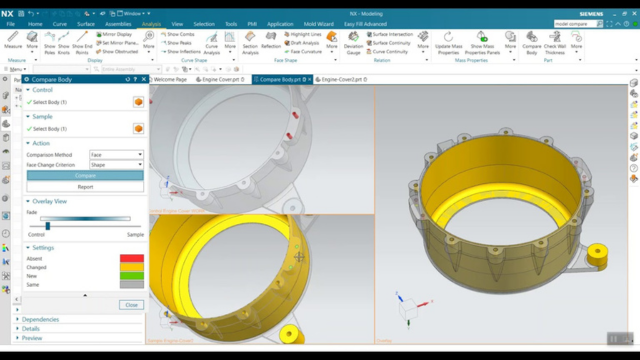

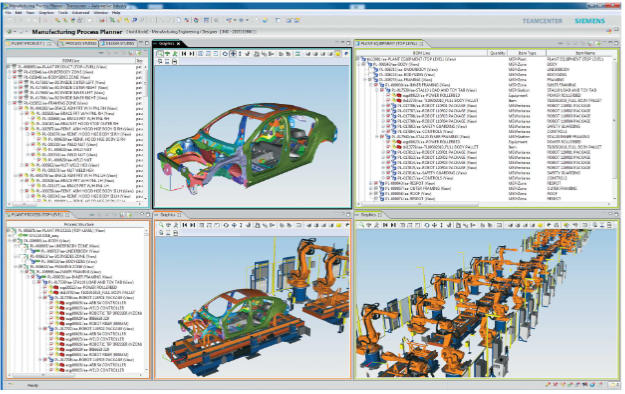

Product data, production processes, manufacturing plans, and resources managed in a single synchronized environment

Product data, production processes, manufacturing plans, and resources managed in a single synchronized environment

Teamcenter Manufacturing enables capturing and managing production data, process information, resource details, and plant data within a unified environment that includes product data. It also offers a comprehensive collaborative workspace that facilitates manufacturing planning, production engineering, and execution through shared information accessible across the enterprise. It supports simultaneous control of processes and resources, allowing real-time adjustments to factory information, processes, resources, and products, ensuring consistency and real-time synchronization throughout the product development lifecycle.

This platform allows departments to use resources for various purposes such as production engineering planning, manufacturing planning, and visually creating electronic work instructions. It improves profitability by identifying more reuse opportunities while minimizing non-compliance risks.

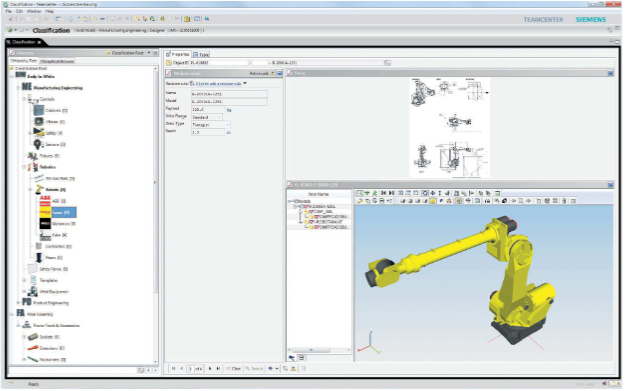

Enterprise manufacturing resources are stored and managed in the system

Enterprise manufacturing resources are stored and managed in the system

Teamcenter Manufacturing focuses on three main entities: people, processes, and enterprise systems. It enables real-time interaction by connecting people, organizational knowledge, and resources.

With its comprehensive capabilities, the solution delivers numerous benefits to businesses, including faster and more informed decision-making, accelerated production, reduced manufacturing costs, early identification of potential issues during product development and production—before they become critical—by enabling production engineering planning in the digital environment from the early stages of product development. It also facilitates efficient resource utilization, capturing and standardizing optimal plans for enterprise-wide implementation.

Read more:

- FPT Software participated in the workshop “Teamcenter Technology Day” organized by Vietbay in collaboration with Siemens.

- Teamcenter – Top PLM software for discrete manufacturers providers evaluated

- Streamline quality audit and assessment with Teamcenter

Contact us for free and detailed advice