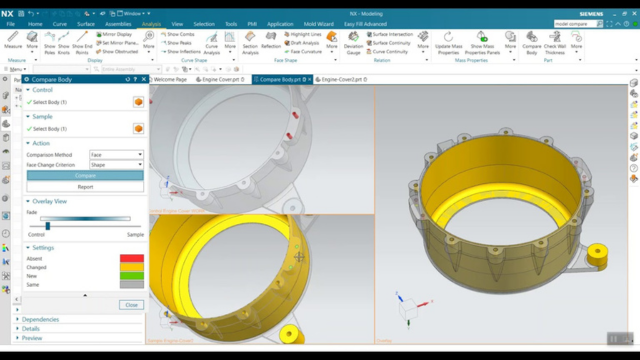

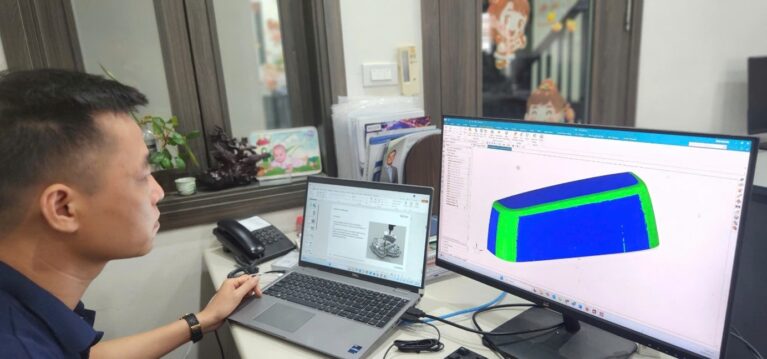

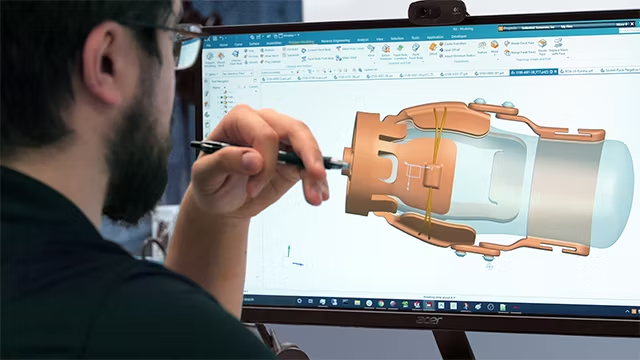

Siemens NX CAM software is currently widely used in Vietnam due to its various advantages, such as the ability to generate toolpaths quickly, flexible toolpath creation, and integration of NC-code machining simulation with the 3D model of CNC machines. This is especially useful for multi-axis machining centers, helping to optimize and ensure a safer machining process while reducing pre-machining test time. Additionally, with the integrated CAD/CAM synchronization capability, NX allows users to easily make design changes and create better CAM machining support tasks.

Beyond programming for fast and optimized toolpath generation, an essential component for any company using NX CAM is the Post Processor.

What is Post Processor ?

The post processor used in CAM software can be simply understood as a converter that translates toolpath data into NC-code compatible with the CNC machine’s controller (such as Sinumerik, Fanuc, Heidenhain, Professional, Mazatrol, etc.). Each CNC controller requires a specific post processor to ensure compatibility.

Why the customer need customize Post processor service for CNC machine ?

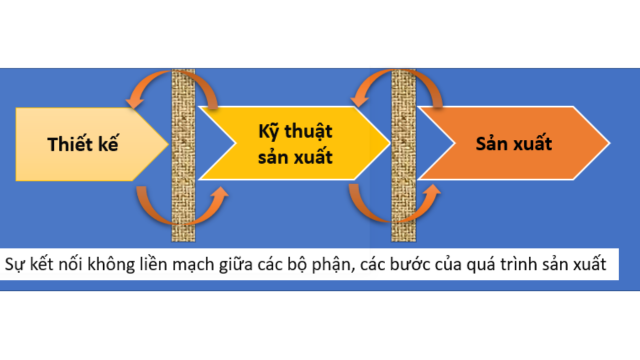

Most CAM programming software includes a library of standard post processors upon installation. However, these libraries are usually not fully compatible with actual CNC machining controllers. Therefore, it is necessary to customize or develop new post processors to match real-world requirements, especially for 3+2 axis milling centers, simultaneous 4-axis, simultaneous 5-axis machining, or mill-turn machining centers.

What are included in Vietbay’s customize Post Processor services?

With 15 years of experience in CAM machining and post processor development, Vietbay’s technical team is committed to providing the best service, ensuring that post processors operate with maximum compatibility, safety, and optimization for your CNC machines. Below are the categories of post processors we offer for various CNC machine models:

- For 3-axis CNC milling machines (Free for customers purchasing NX software from Vietbay)

- For 3+1 or 3+2 axis machining centers

- For simultaneous 4-axis milling centers

- For simultaneous 5-axis milling centers

- For CNC lathes

- For mill-turn machines

Process to provide Post Processor services for our customers

- The customer provides complete information about the CNC machine, controller, and its version.

- The customer provides a sample NC file or NC Archive file from the controller and corresponding G-code, M-code documentation.

- Vietbay develops the post processor and tests it through simulation on a virtual model.

- The post processor is tested on an actual CNC machine for real product machining.

- Feedback is recorded, and adjustments are made if necessary.

- The post processor is retested and officially delivered.

- Warranty and user guidance are provided during customer usage.

Some Projects and Complex CNC Machines for Which Vietbay Has Customized Post Processors

Up to now, we have successfully provided Post processor services for numerous customers with complex multi-axis machining centers, earning their trust and satisfaction. Some of our notable clients using this services for multi-axis machining centers include Honda Vietnam, Nakashima, Big CNC, Cosmos, Hanoi University of Industry, Intop, SEMV, and many others.

We have customized post processors for various CNC machines and controllers, such as:DMU 50 (Siemens 840D). Makino D800Z (Professional), DMG NHX8000 (Fanuc), Makino N2-5XA (Professional), Roeders, Okuma, DMU210P2 (Siemens 840D), Heidenhain, etc. Additionally, we have created numerous post processors for 3-axis CNC machining centers.

Read more:

- Vietbay completed implementation of smart manufacturing and product lifecycle management solutions

- Automating Wire EDM Programming with NX CAM Advanced Wire EDM (OptiCAM)

- Improve productivity and quality in CNC machining with Siemens NX CAM