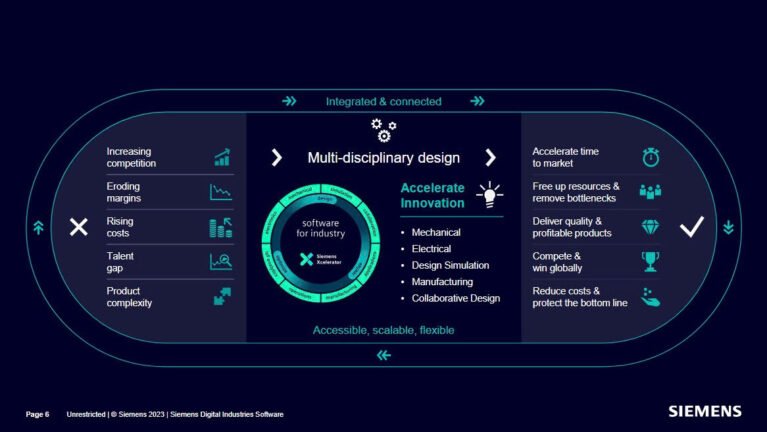

Non-enterprise companies now face increasing global competition, all aimed at bringing products to market faster while reducing costs. Encouraging these businesses to adopt advanced, digital technologies is often met with resistance due to complexity, cost, and lack of resources. Products are becoming ever more complex across all industries, and customers are demanding more personalization while the life cycle of products is shrinking. As a result, many non-enterprise companies face additional complex and costly engineering challenges to ensure the quality and performance of their products, while managing challenges in delivery schedules and timelines, as customers ask for faster delivery to meet more rapid product launch demands. However, they often lack the technology or resources to face these challenges, and instead choose to live with the status quo. This is a recipe for disaster, and it cannot sustain a growing — not to mention competitive — business.

- They need to enable their designers and engineers to easily do their job to innovate and deliver complex designs that are right the first time without the constraints of inefficient or disconnected processes.

- They need to speed time to market by reducing bottlenecks and costs and utilize existing expertise by bringing simulation and testing in-house.

- They need to access and share real-time design and production data to immediately address customer needs and issues as they occur.

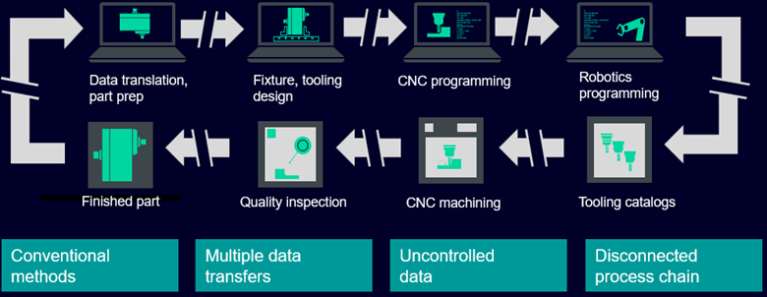

Many non-enterprise companies are using software that is not integrated with their processes. They lack the means to do any in-house machining and/or simulation, which increases costs and delays. These companies also lack the ability to effectively manage data across the product lifecycle, resulting in additional delays and quality issues. Although they are experiencing rising consumer pressure to rapidly introduce innovative features and new technologies, their ability to plan for production and execute on increasing design needs is in limited supply. And the addition of an IT landscape that has become increasingly complex will inevitably lead to errors, reduced quality, and delay schedules.

Siemens’s solution Accelerated Engineering for SMBs focuses on expanding the growth of a business by accelerating design engineering processes using a single digital environment. Currently, many of these businesses are using software that may be disconnected from other systems. What is lacking in-house is outsourced, making it harder to ignore gaps within the process.

The Accelerated Engineering digital thread provide a single digital flatform the SMB to solve all of customer engineering challenges

1. Process design efficiencies

With an open solution you can create a collaborative environment that streamlines the design process. By concentrating on the workflow and not just “picks and clicks,” increasing data re-use, and model edits (regardless of where they come from), you enable your engineers and designers to explore more options in less time to find the best design to meet production specifications.

2. Seamless integration

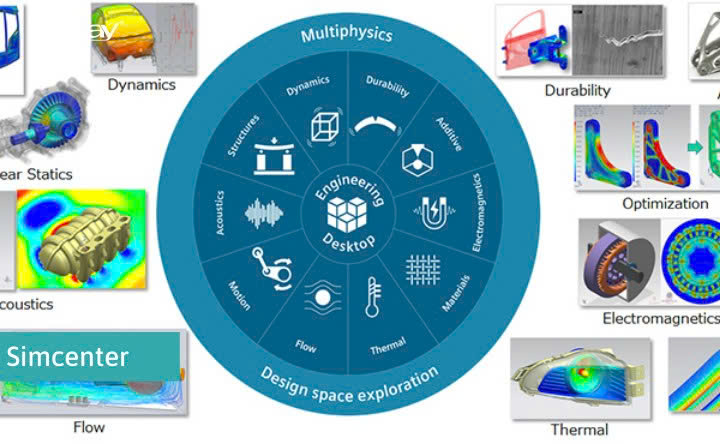

With a common engineering solution, you can work across disciplines, create, edit, and import or re-use models of complex products or systems, and seamlessly connect with data and CAD management. With out of the box CAD integrated simulation, you can increase rapid prototyping to bring products to market faster, predict performance across multiple disciplines, and increase expertise internally to drive innovation and productivity in test-based engineering.

3. Data visibility and collaboration

Moving from static spreadsheets or reports, you can create a collaboration and sharing of data that extends across the whole supply chain. With an integrated PLM process, you now have end-to-end traceability, disciplined processes, and reusability. You can execute workflows and manage configurations for complex assemblies and improve BOM management.

Four key solutions

- Generative geometrical design: Focus on quickly design from concept to detail with complex product, integrated mechanical design and Eletronics, electrical design. Flexible software bundles base on customer’s products and requirements. Core product on this solutions included NX, Solid edge, Capital

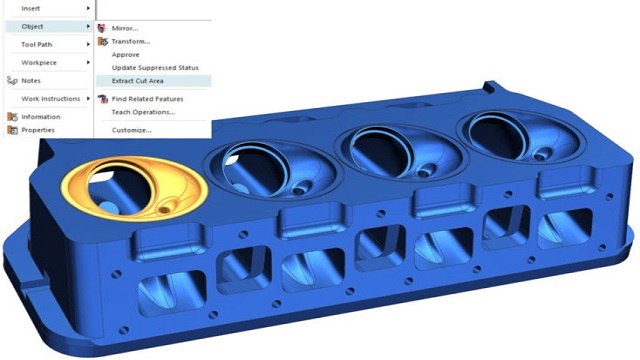

- Simulative performance verification: Forcus on Simulation to performance Product design with direct integrated design software. The core product in this solution is Simcenter, it help customer quickly simulation and verification of product design before manufacturing, reduce development time and cost, faster go to market.

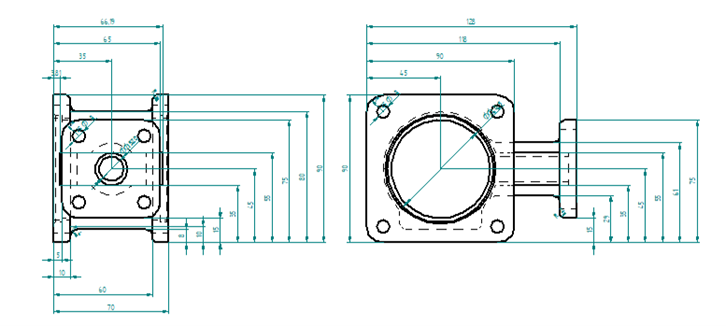

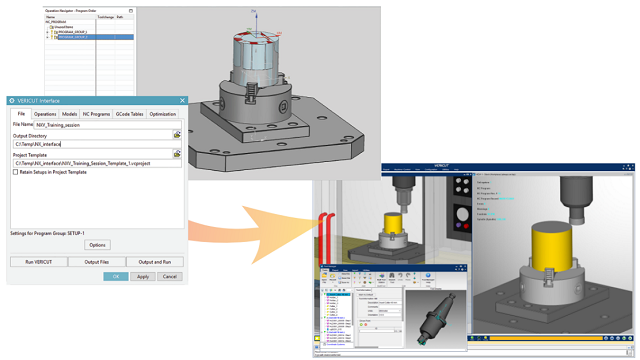

- Manufacturing Programing: This solution included full capability for CNC macnufacturing from prepare data, programing to NC simulate with virtual CNC machine based on NX CAM software

- Efficient processing of design changes: This solution included digitial flatform to collaboration between departments or suppliers. The solution will help manage data, document, BOM, workflow, connect with suppliers or OEM based on Teamcenter

Four key themes for this specific digital thread

- Information transparency – Integrate and collaborate across all aspects of distributed design and supply chain

- Shorten Cycle Time – Streamline workflow, improve BOM management, and increase rapid prototyping to bring product to market faster

- Affordable cost of entry and deployment – Implement integrated product design, engineering, and design simulation without breaking the budget

- Talent – Attract and retain top talent with the adoption of advanced technologies while balancing the perceived costs

Read more:

Contact us for free and detailed advice: