Simcenter 3D Structures is a powerful structural analysis module within Siemens’ Simcenter 3D, built to help engineers simulate the entire mechanical behavior of a product in a single, integrated environment. This solution reduces modeling time, increases simulation accuracy, and improves product development efficiency across a wide range of industries, including aerospace, automotive, industrial equipment, electronics, and energy.

Outstanding advantages of Simcenter 3D Structure include:

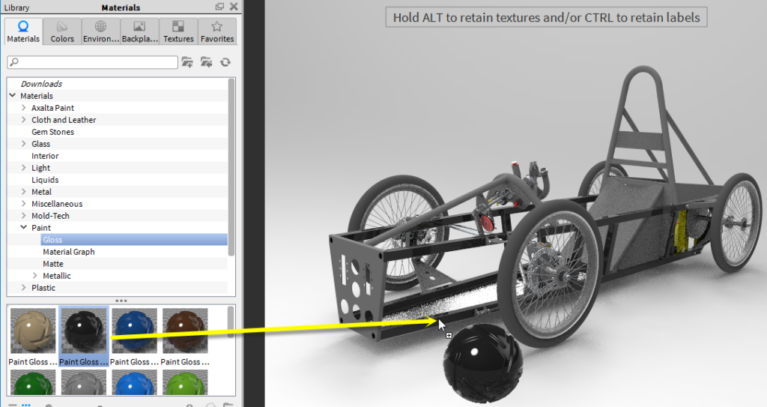

1. Integrated CAD/CAE simulation environment

Simcenter 3D Structures provides a unified environment for:

- Geometric modeling and pre-processing

- Create smart, automatic meshes, including a variety of 0D, 1D, 2D, 3D meshes

- Set up boundary conditions, loads and material properties

- Computation and post-processing

By integrated with NX CAD , users can reduce the time it takes to convert CAD models to simulation models by up to 70%, easily change designs and update data to the simulation environment without having to re-work it.

2. Comprehensive structural analysis capabilities

Simcenter 3D Structures fully supports all types of analysis from basic to advanced:

Linear Analysis

- Linear stress-strain

- Modal, resonpse dynamic

- Structural stability (buckling)

Nonlinear Analysis

- Material nonlinearity (plasticity, hyperelasticity…)

- Large deformation

- Complex contact between parts (contact simulation)

Reponse dynamic analysis

- Transient response

- Harmonic response

- Shock & random vibration – suitable for environmental and electronic product testing

Fatigue analysis

- Evaluate the product’s shelf life

Multiphysic analysis Analysis

- Structure-thermal

- Structural simulation under harsh working conditions

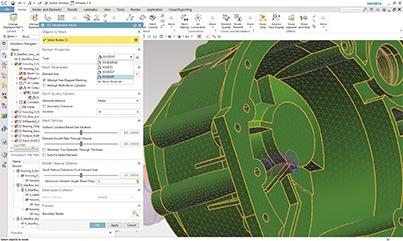

3. Advanced design optimization and simulation

Simcenter 3D Structures integrates modern technologies:

- Topology optimize to reduce weight while ensuring durability

- Design optimization based on design parameters and physical properties

- Composite material simulation with ply modeling, draping and failure analysis

- Manufacturing Simulation such as welding, machining, forming to evaluate residual deformation

4. Integration with powerful solvers

Simcenter 3D Structures supports many leading solvers:

- Simcenter Nastran – traditional solver strong in linearity, dynamics, buckling, optimization

- Simcenter Samcef – specialized for nonlinear, composite simulation, motion structures

- Abaqus, ANSYS, LS-DYNA – support model linking or exporting

This gives businesses the flexibility to leverage existing infrastructure or combine multiple tools in a unified process.

5. Automate the simulation process

Simcenter 3D supports:

- Create simulation template

- Process capture

- Automate the iteration problem

- Integration with Teamcenter for Simulation Data Management (SPDM)

As a result, businesses can standardize CAE processes and significantly reduce repetitive efforts.

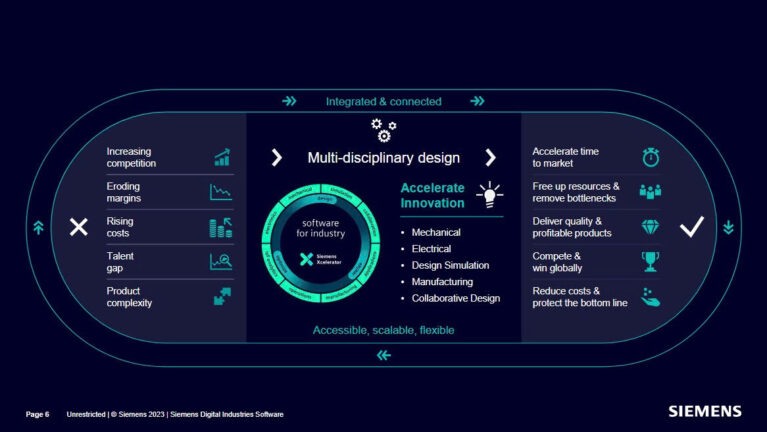

6. Outstanding benefits

- Reduce model preparation and simulation setup time

- Increased accuracy due to close association with CAD model

- Reduce the risk and cost of physical testing

- Optimize design from the beginning

- Multi-disciplinary integration within the same Simcenter ecosystem

With a team of experts with many years of experience in consulting, training and transferring CAD/CAM/CAE technology. Vietbay is committed to providing customers with the most optimal and suitable solutions and services. We have provided Simcenter and transferred technology to many large customers in Vietnam such as Samsung, Clark, FPT Soft, Honda, Viettel, products that our customers are applying Simcenter for many different fields such as 5G, forklifts, cars, …. For structural strength problems, vibration problems, shock vibration, …

Read more:

- Post Processor Service for NX CAM

- Solutions For Design And Performance Optimization Of Unmanned Aerial Vehicles (UAV)

Contact us for free and detailed advice: