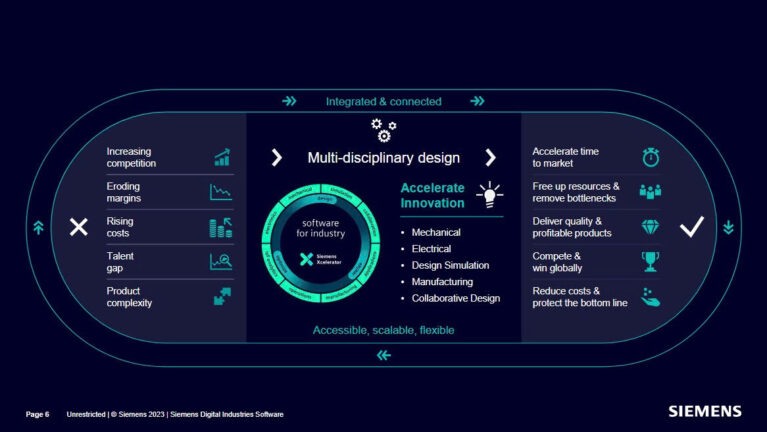

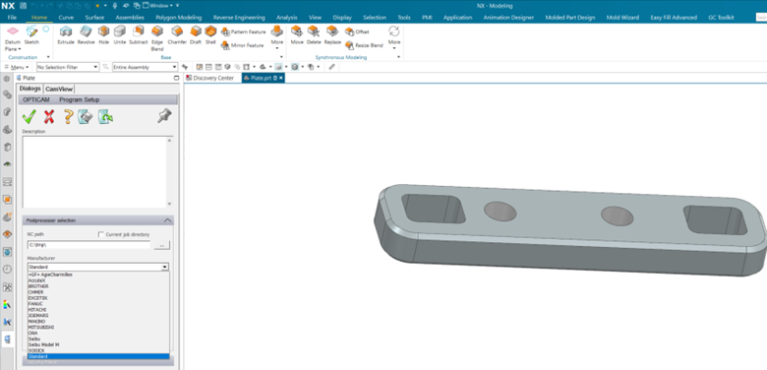

Currently, NX is a very popular and widely used software in Vietnam, with many diverse and powerful feature modules that can be applied in most industrial fields, especially the automobile, motorbike, mold and die, Aerospace industries… In which NX CAM is a very powerful software module for CNC machining, to complete its solution and support customers with synchronous solutions in manufacturing, Siemens has integrated a specialized software module OptiCAM wire cutting with many outstanding advantages.

Key Features of OptiCAM

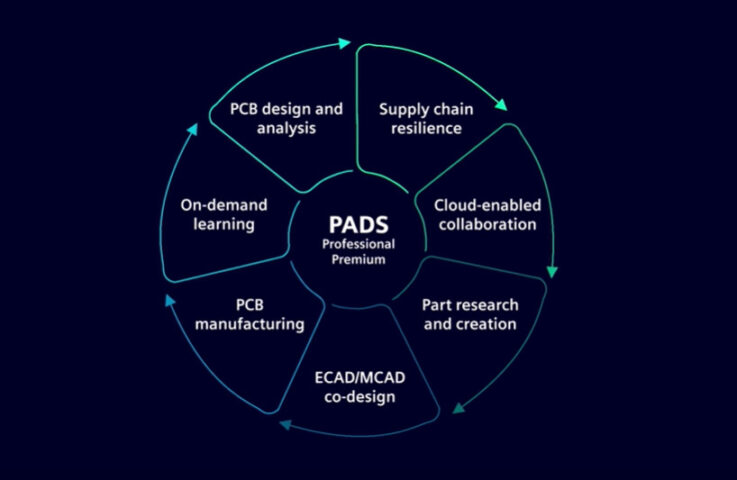

OptiCAM integrates the ability to automate 100% of programming while also allowing programmers to customize manual programming for special cases. Additionally, this software includes a built-in post processor compatible with most wire cutting machine brands such as Sodick, Makino, AgieCharmiles, Mitsubishi, Hitachi, Fanuc, Excetek, Seibu, ONA, AccuteX, CHMER, Brother, and JOEMARS. This enables engineers to program directly within the NX CAM environment, eliminating the need for programming on EDM machines, thereby shortening time and synchronizing processes on a single CAM software platform.

Main Features of NX OptiCAM

Automatic Geometry Recognition: Automatically recognizes geometric data and creates EDM wire cutting machining programs from original design data, fully automating all processes.

Support for Various Geometries: Programs machining for geometries like straight holes, tapered holes, and rule faces.

Punch Cutting Programming: Supports punching cutting programming (Pocketing) for various surface geometries.

Wire Hole Position Recognition: Automatically recognizes wire hole positions (Start hole), allowing users to edit positions freely.

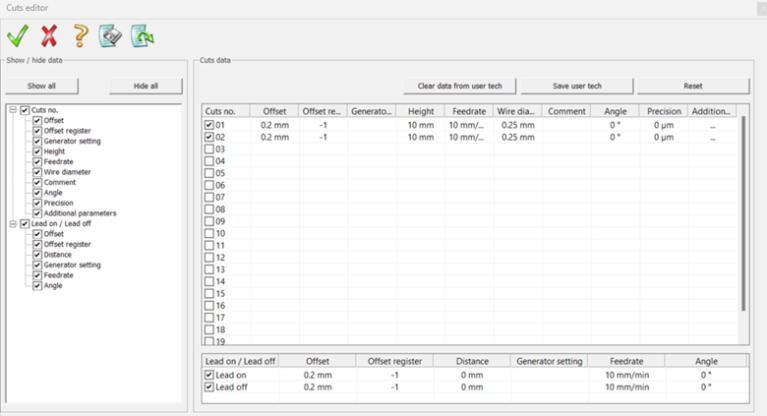

Flexible Lead-In/Lead-Off Adjustments: Provides flexibility in lead-in and lead-off adjustments according to different strategies in straight or circular arc forms.

Easy Event Definition: Enables easy definition of events (Event) at any position along the cutting path.

3D Machining Simulation: Simulates machining in a 3D environment to evaluate collisions, validate machining programs, and calculate machining time.

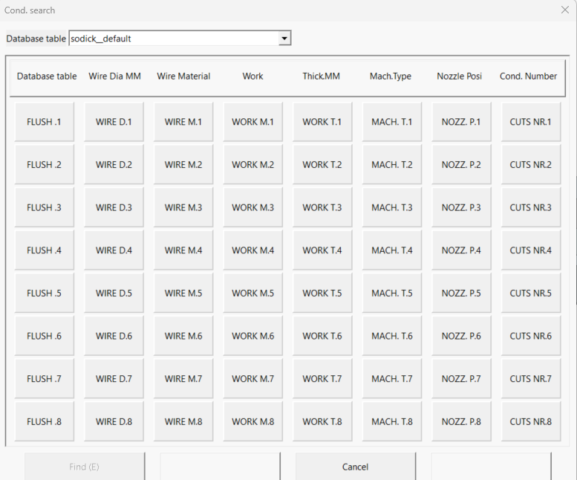

Integrated Cutting Technology Data: Includes built-in cutting technology data corresponding to different wire cutting machine manufacturers, facilitating easy programming and setting of suitable cutting parameters.

Compatible Post Processor: Contains a post processor compatible with most EDM wire cutting machine brands, ensuring a smooth machining process.

Benefits of Integrating OptiCAM with NX CAM

Leveraging the advantages of NX software in design and CNC programming now becomes more comprehensive with advanced wire cutting programming tools. Customers can seamlessly integrate from design, milling, turning, to wire cutting on the same software platform. This minimizes data conversion time and ensures automatic updates when design changes occur, providing consistency in the manufacturing process.

Read more:

Contact us for free and detailed advice: