For years, structural simulation (FEA) has been tied to a workflow of geometry preparation – meshing – refinement – computation. This process often consumes the majority of engineering time, especially when models become complex, contain many small details, or include large assemblies. Altair SimSolid introduces a completely different direction: eliminating the meshing process entirely while still producing high-accuracy results on fully detailed assemblies.

1. Core Philosophy: Geometry-Based Analysis

Instead of converting geometry into finite element meshes, SimSolid uses an advanced mathematical approach based on geometric tolerance analysis combined with multi-resolution test functions.

This allows the software to:

- Work directly with native CAD, STEP, or Parasolid models without any cleanup.

- Preserve all geometric details—small fillets, threaded holes, or intricate features.

- Deliver accurate stress and displacement results even in regions with highly complex geometry.

This approach differs fundamentally from traditional FEA, which often requires removing details to create a workable mesh.

2. Significantly Faster—Without Sacrificing Reliability

SimSolid’s standout strength is speed. Static, modal, or thermal analyses can be completed in seconds to minutes, even for assemblies containing thousands of parts.

Key advantages include:

- No meshing → eliminates 70–90% of model preparation time.

- No need for auxiliary modeling such as bonding meshes or shell-mesh simplification.

- Automated computation settings that do not require deep meshing expertise.

This drastically shortens design decision cycles and enables rapid design iterations.

3. Designed for Use Directly in the Design Stage

SimSolid is built not only for CAE analysts but especially for design engineers.

With its streamlined interface and simplified workflow, designers can:

- Validate structural performance as soon as the 3D model is created.

- Explore multiple design alternatives without spending time on cleanup.

- Confirm design feasibility before passing models to CAE specialists.

This greatly reduces design rework and increases product quality from the earliest stages.

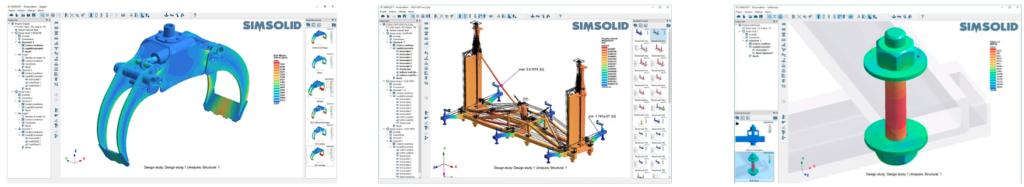

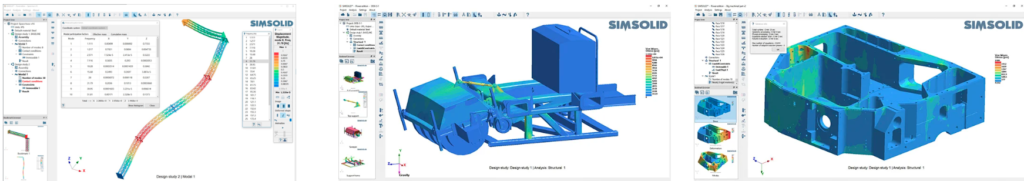

4. Ideal for Complex Assemblies

SimSolid is particularly strong for products with large, detailed assemblies such as:

- Steel structures and heavy machinery frames

- Robot frames, machine bases, vehicle substructures

- Industrial equipment and enclosures

- Welded structures, bolted joints, flanges, etc.

The software automatically identifies all contact types (bonded, sliding, pinned, bolted) without surface-to-surface meshing.

5. Deep Integration into the Product Development Process

Altair provides seamless connectivity between SimSolid and CAD/PLM/CAE environments, allowing users to:

- Sync models from CAD to SimSolid with a single click.

- Export results to HyperWorks or Inspire for advanced optimization.

- Combine simulation and design in one iterative, integrated workflow.

6. Simulation for the ‘Speed Era’ of Product Development

With rapid design cycles, stricter quality demands, and shorter development schedules, SimSolid becomes an ideal tool.

Overall benefits include:

- Huge reduction in model preparation time

- Lower simulation costs

- Accelerated design innovation

- Accessible for all engineers—no deep FEA knowledge required

- Ability to evaluate many design variations in extremely short time

Conclusion

Altair SimSolid is not merely a faster FEA tool—it represents a new approach to simulation.

By removing meshing, simplifying workflows, and delivering trustworthy accuracy, SimSolid enables engineers to focus on what matters most: making fast, informed design decisions.