What Is Reverse Engineering?

Reverse engineering is the process of collecting data from a physical product (prototype or sample) in order to reconstruct a 3D model and technical drawings. This process is especially useful when:

- The original design files or drawings are missing.

- You want to improve or replicate an existing product.

- You need to repair or restore worn-out or obsolete components.

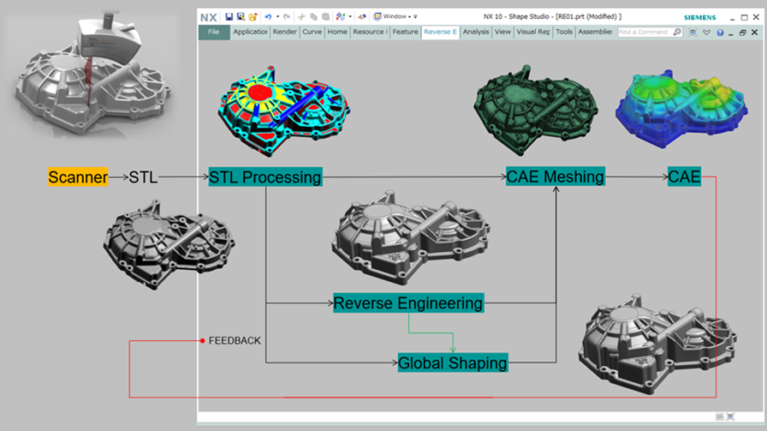

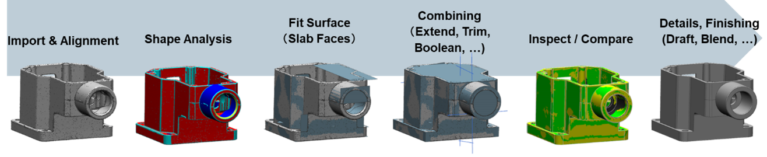

Our Reverse Engineering Workflow With NX:

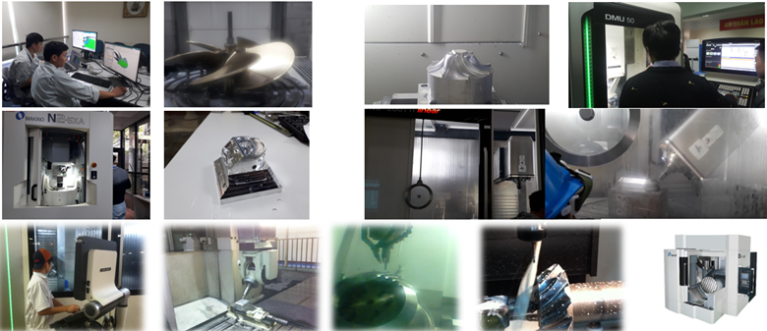

- Data collection: Scan the physical sample using high-precision 3D scanners.

- Mesh processing: Clean up, filter noise, and refine surface structures.

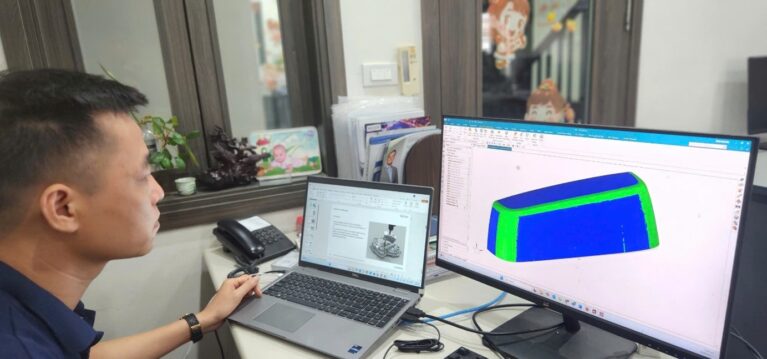

- 3D CAD modeling: Use NX’s reverse engineering tools to recreate the parametric model.

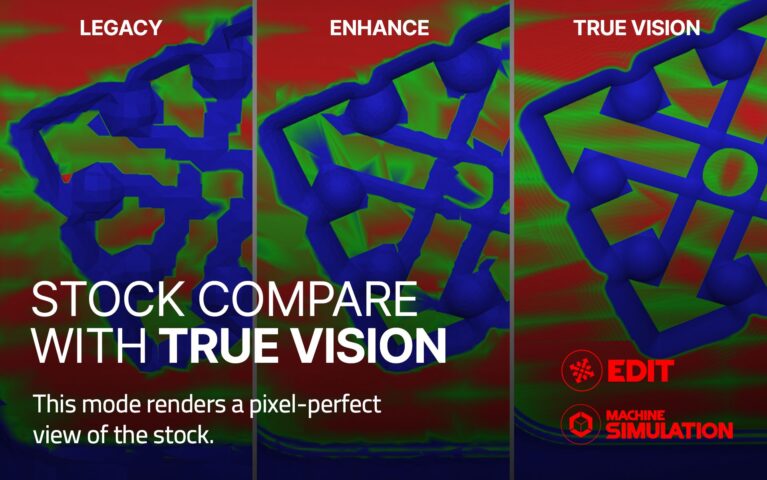

- Inspection and validation: Compare the new model with original scan data to ensure accuracy.

- Generate Accuracy report

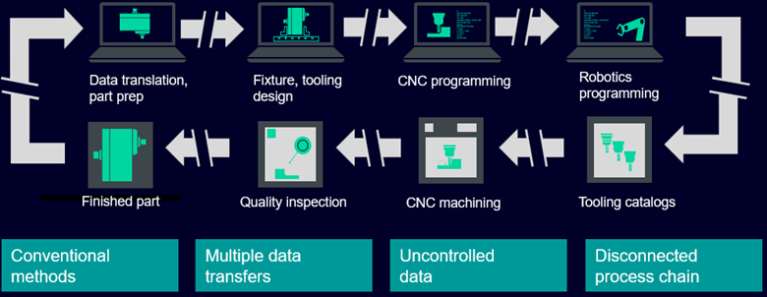

- Export for production: Provide technical drawings or CNC programe with CAM as needed.

Why Vietbay?

- Fast – Accurate – Cost-effective

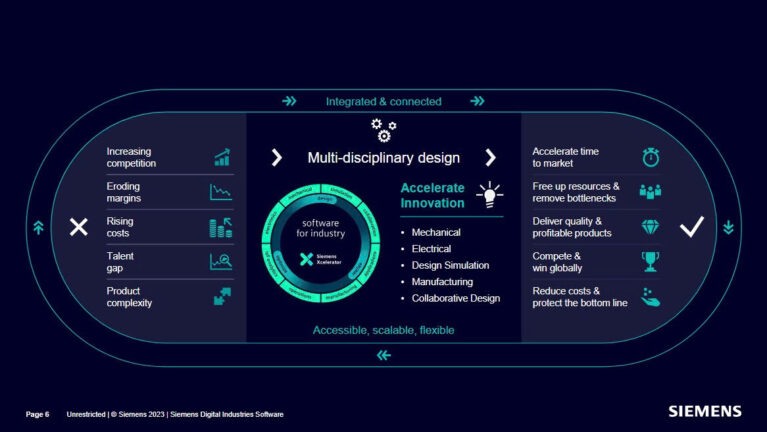

- Utilizes advanced Siemens NX software with precise 3D scan data support

- Experienced engineering team with deep expertise in mechanical design and manufacturing

- End-to-end support: from 3D scanning to CAD/CAM/CAE delivery

- Guaranteed confidentiality and top-quality standards

Our Services Include:

- 3D scanning of physical samples using advanced technology

- Mesh data processing and 3D CAD model creation

- Adjustment and accuracy verification

- Export of technical drawings and 3D models ready for CNC machining or 3D printing

Common Applications:

- Mechanical engineering – Mold making

- Automotive – Motorbikes – Electronic components

- Medical devices – Industrial products

- Maintenance, replacement, or restoration of rare parts

Read more:

- Multi-Axis CNC Machine Configuration And Machining Simulation Services

- Post Processor Service for NX CAM

Contact us for free and detailed advice: