A best-practice strategy to keep your projects on time and on budget is to test them for compliance with your manufacturer’s capabilities before you hand it off to manufacturing for production. Implementing Design-for-Manufacturing (DFM) as a standard practice so you can hand off a clean design to avoid time consuming and frustrating back and forth with your manufacturer, will significantly improve product quality and time to market.

One of the products that meet the above requirements is PADS Professional Premium DFM. Here are some frequently asked questions

1. Is this a new product? What’s included?

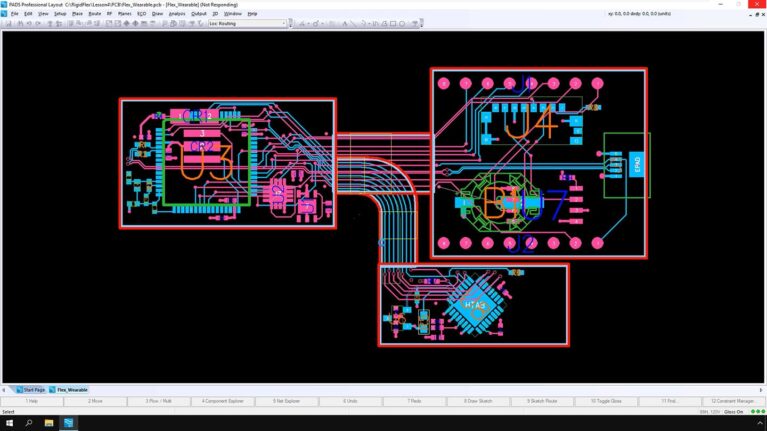

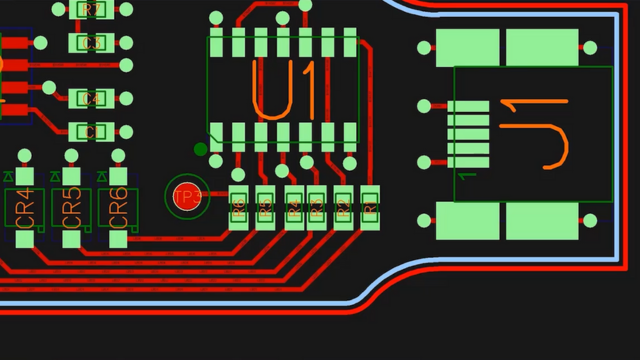

PADS Professional Premium DFM is a solution that includes all the functionality of PADS Professional Premium with the addition of DFM capabilities.

2. If I purchase PADS Professional Premium DFM, can I also run DFM directly from PCBflow.com or do I have to purchase that separately?

When you purchase PADS Professional Premium DFM, you can run the DFM checks directly from PADS Professional Layout. This is our recommended fully-integrated flow. That said, you can also use the same login information that we provide to log in to PCBflow.com and run Design for Fabrication analysis there. PCBflow is a Siemens cloud-native tool dedicated to DFM. However, because it is an independent login, you will lose the ability to sync with your on-premises PADS Professional layout tool – you will have to upload your design directly to the PCBflow platform and review the results there or download them to an Excel/PDF format rather than reviewing them directly within your layout tool.

3. Do you check my component placement?

Currently PADS Professional Premium DFM includes only fabrication checks, no Bill-of-Materials (BOM) information is used for these analyses. If you have a BOM and you need to run assembly checks such as component spacing, footprint compliance etc, you will need to run that separately from PCBflow.com

4. Can I create my own DFM rules?

Absolutely. If you log in to PCBflow.com, you will find an area called Manufacturer Tools. Use the tool found there to create customized DFM profiles for your own use. However, before you do that, I suggest that you try running with our default profiles to get an idea of how the checks work and then you can use them as a base for customization. I’d also suggest that if you don’t find your fabricator in PCBflow.com, PLEASE reach out to us and let us know and we can try to get them onboarded instead of having you double the work.

5. Is there a limit to how many times I can run DFM?

You can run these DFM checks as often as you like throughout the 12-month subscription period to PADS Professional Premium DFM. We provide an unlimited number of DFM runs because we believe DFM is best applied as part of an iterative process during layout.

6. Where can I read more about data security for PADS Professional Premium DFM?

First, there is a White Paper titled, “Modern day security practices safeguard a digital transformation” that reviews all of our Siemens EDA security practices. Second, there is a Siemens Trust Center website that is a one-stop resource for our policies, compliance, and global data security standards. You can also go to the pcbflow.com website and in the resources section you will find an entry for data security.

7. Is there a list of DFM checks I can look at before I purchase?

On the pcbflow.com website, you will find a button right there at the top called “DFM Check List”, which shows you a searchable list of all the checks PCBflow can perform. As well, the list is available from within the software.

8. What is the difference between these DFM checks and our regular DRC checks in the CAD tool?

In general, DRC checks are designed to see if your board is compliant with electrical limitations like interference, whereas the purpose of DFM checks is to determine if the board can be manufactured well or even at all. As well, there are several checks available in the DFM family that are not the focus of DRC, for example: copper spacing vs copper slivers, or netlist analysis.

9. Do we have corporate licenses for your products? My company already uses of HyperLynx mostly for Signal Integrity and Power Integrity analysis and Validation.

If you already have Siemens tools, we suggest contacting your Account Manager for details of how best to add DFM capabilities to your existing corporate licenses.

10. Can PCBs created from other tools be loaded in PADS and then carry out the PADS flow analysis

Yes. You can import PCB designs from other tools into PADS Professional Premium DFM and then you can run DFM analysis on it.

11. Is the format for the DFM rules that the manufacturer has to provide, PADS proprietary, i.e. do they also need a PADS license?

Manufacturers who want to provide customized DFM rules (we call them “DFM profiles”), can do so FOR FREE, with NO LICENSE REQUIREMENTS.

12. Can client and manufacturers communicate over the platform? If need some changes in the design or EQ (Engineering Queries) can they be discussed in this tool?

Yes. PADS Professional Premium and PADS Professional DFM include full collaboration capabilities. So, a product development team can fully collaborate between team members (design/file management, sharing designs, 2D and 3D visualization, markup, notifications, etc.). Also, a development team can also collaborate with external 3rd party stakeholders using the same collaboration capabilities. We have gone to great lengths to manage this process in a secure manner.

13. Hello, how do you define the edge between a “good” or a functional/practical DFM Model and a over-engineered tool?

Excellent question! A functional DFM profile will contain rules that pertain to real-life production capabilities. It will give you actionable information about real problems that prevent manufacturing or make it expensive. An over-engineered profile will return results that are irrelevant to the manufacturing environment, or do not reflect a true ‘digital twin’ of the factory.

Learn more about PADS:

1. PADS PCB design software & collaboration tools

2. PADS Professional Premium Edition

4. PADS Standard and PADS Standard Plus

For more information, please contact: