December is here, and with it comes the excitement of the holiday season, the anticipation of the new year and a new release of NX CAM software. We are excited to announce the latest version of NX for manufacturing With the addition of powerful new capabilities and enhanced functionalities to your part manufacturing solutions, you can achieve higher levels of productivity using the NX software.

What’s new in NX CAM

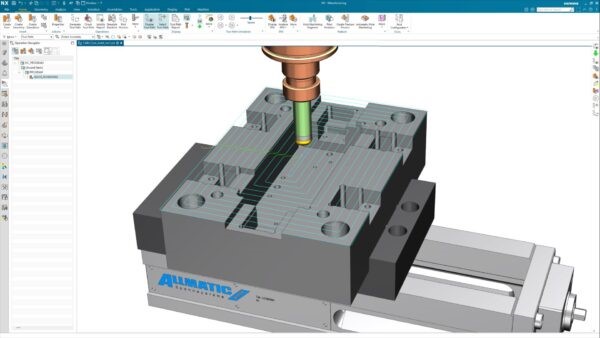

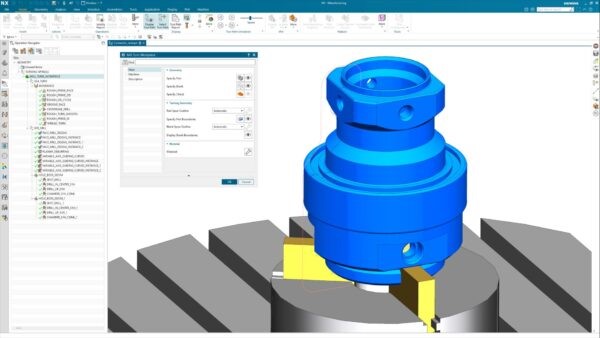

Quick Roughing

The new Quick Roughing operation in NX CAM software offers a swift and easy-to-program offset roughing process with a user-friendly interface and streamlines the creation of roughing operations with minimal input, saving valuable programming time. It is ideal for programming simpler components, such as prismatic parts and less complex molds, cavities, and cores, dies, castings, and forgings with contoured shapes using planar cut levels. The new roughing method automatically applies the most efficient cutting strategies to different region types, such as open and closed regions. The improved quick roughing feature ensures robust holder collision avoidance while maintaining the right holder clearance v

alues, enhancing not only the safety and reliability of the machining process but also the overall efficiency and quality of the produced parts.

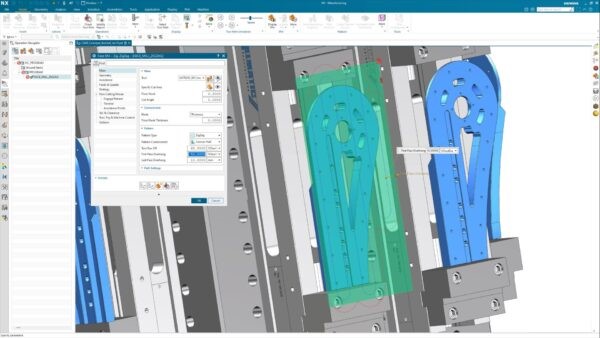

Face Milling

The new Face Milling operation provides modern programming techniques to interactively adjust toolpath parameters, improving your programming efficiency. Face Milling operations have been significantly improved. The new Face Milling operation, featuring zig and zig-zag patterns now makes it easier for users to program face milling toolpaths. The interactive on-screen UI allows users to effortlessly specify path parameters like Cut Angle, Run Off, First Pass Overhang, Blank Thickness, Start Point, and Floor Stock, providing them with automatic toolpath previews and ensuring faster toolpath generation.

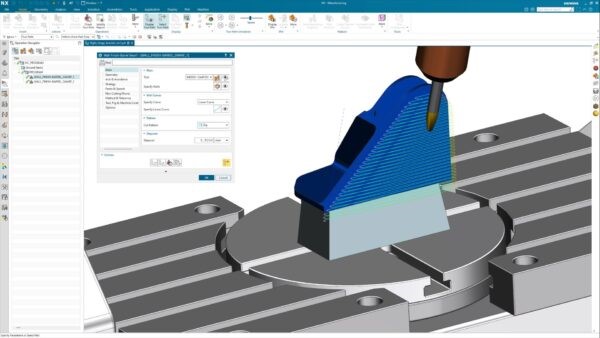

Wall Finish Barrel Swarf

The latest Wall Finish Barrel Swarf operation helps you reduce machining time and improve surface finish using advanced settings to generate optimized toolpaths easily. You can now use taper barrels for parts with straight walls and tangent barrels for parts with curved walls. With the newly introduced 5-axis Wall Finish Barrel Swarf operation subtype, you can also swarf deep planar or contoured walls using a 5-axis tool motion with tangent barrel, taper barrel, and standard barrel tools.

Holemaking enhancements

The user-friendly and enhanced Holemaking features now make it easy to manage control points during drilling and pilot drilling, especially when working with depths less than the In-Process Workpiece (IPW) stock. The new control point option called “Use initial” ensures the tool consistently positions itself above the Initial Programmed Workpiece (IPW) for each operation, preventing sudden movements into the previously drilled hole.

Mill Turn Workpiece

This results in safer toolpaths with increased control, minimizing the risk of tool breakage and better control for entry into the hole. Users can now choose the clearance depth from the bottom of a hole or boss, reducing the depth a tap or thread mill goes into a threaded feature. This solution gives users complete control over how far the threading tool stops from the bottom of the feature.

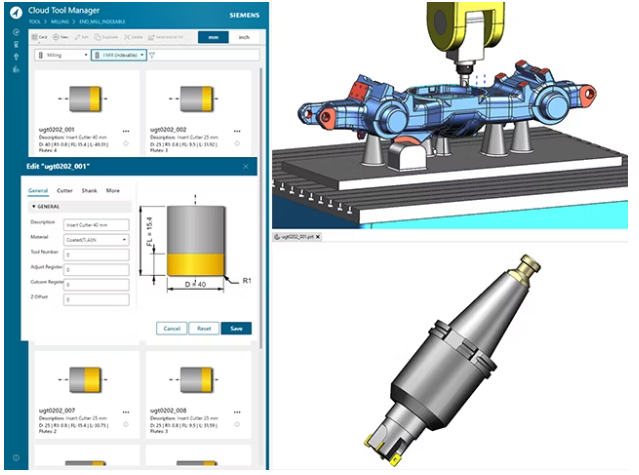

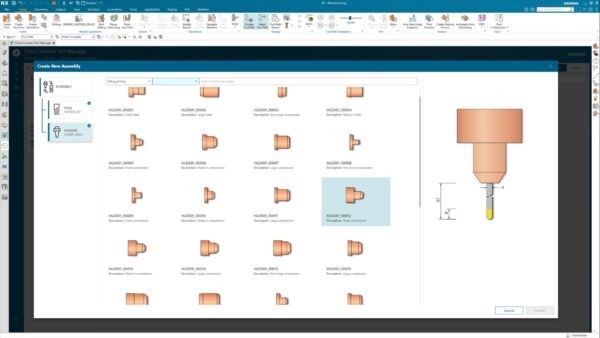

With the upgraded Cloud Connect Tool Manager, you can effortlessly generate entire tool assemblies using the dynamic assembly tool preview. With the inclusion of tool holders in the latest release, you can seamlessly create tool assemblies with tool holders and cutting tools. The module supports several search functions for added convenience.

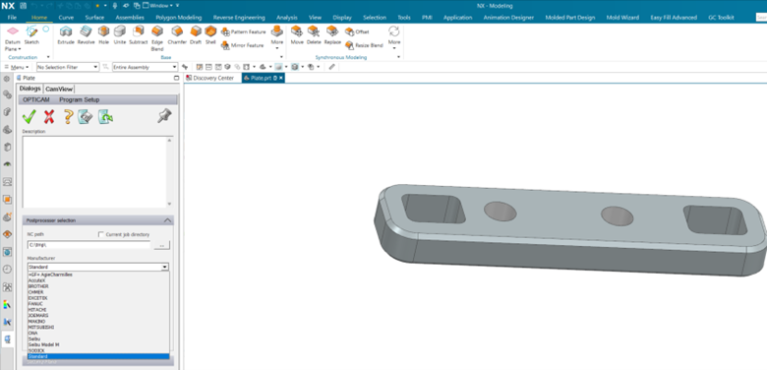

The latest Mill-Turn Workpiece feature offers a more intuitive and faster creation of advanced mill- turn CAM setups. This enhancement, available for use only when a machine tool is loaded, has reduced the need for additional setup efforts. It achieves this by combining the definitions of Milling and Turning Workpieces into a single geometry object, streamlining the programming process, and simplifying the geometry tree for more user-friendly mill-turn setups.

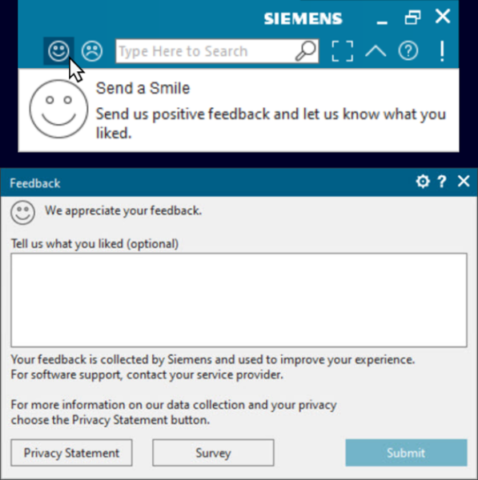

NX CAM feedback

Your software feedback is extremely valuable to us, That is why we actively incorporate your input. to improve the overall CAM experience by turning your feedback into new features and improvements. Now within NX CAM, you can provide feedback anonymously using a simple survey submission process without difficulty. Share detailed insights, ensuring your input is delivered directly to the NX CAM Product Owner for a thorough review.

“Quick Roughing in the latest version of NX CAM is extremely practical for NC programmers. First, it’s simple to use. I can create great roughing operation with just a few clicks. Plus, it’s very fast! Compared to other methods, Quick Roughing can cut the toolpath calculation time by up to 50%.”

Andre Luis , Director, Cadcamnx Worldwide

Source: Siemens

Vietbay has 20 years of professional operation in the field of consulting and technology transfer of IT software and technology solutions for optimal design, processing, simulation, analysis, evaluation and life cycle management solutions. products (CAD-CAM-CAE-PLM). Vietbay is the first Distributor and Gold Partner of Siemens Industries Software in Vietnam, the main Partner of Autodesk, Vericut , CIMCO, WorkNC… Especially VTC – Vietbay Training Center is an Authorized Partner of Siemens Industries The software trains according to the company’s standard curriculum and issues certificates according to international standards from Siemens or prestigious certifications from Vietbay throughout Vietnam.

Contact Vietbay for direct advice on smart manufacturing technology solutions , comprehensive factory digitization, integration and synchronization in accordance with the 4.0 Industrial Revolution trend in the electronic and automotive components industries . motorbikes, molds, consumer goods, industrial machines…