Complete engineering solution for PCB assembly and test

Introduction about Valor Process Preparation

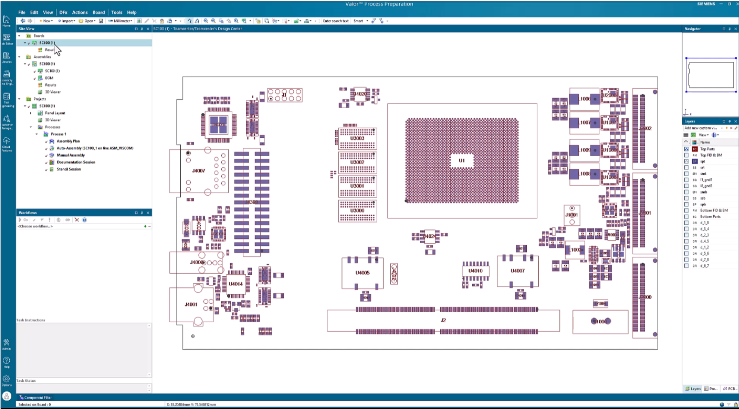

Valor® Process Preparation solution provides manufacturers with everything they need to accurately and efficiently run the manufacturing process while saving costs. Valor Process Preparation offers a unique approach that creates a single, central database of all manufacturing process definitions (MPD) and engineering data, leveraging ODB++ Design and bill of materials (BOM) files.

The true client-server application

The true client-server application reduces work in process (WIP), increases overall equipment effectiveness (OEE) and enables you to achieve a streamlined flow in your production process. Surface mount technology (SMT), through-hole technology (THT), stencil design, hand work, box build, electrical test and both optical and X-ray inspections are all supported for maximal advantage. It is easily configured for your specific workflows, including data preparation, design-for-assembly (DFA) analysis, documentation, SMT programming, test and inspection engineering, and stencil design – all in one seamless, cohesive solution.

Valor Process Preparation helps you improve yield by promoting an error-free manufacturing process. It gives you the flexibility to move between machine vendors and different manufacturing sites and to optimize your SMT programs, which is essential for optimized productivity and manufacturing

Ability of Valor Process Preparation

- A single engineering tool for error-free manufacturing

- A single data model for all processes and vendors

- Design anywhere, build everywhere

- Preserve knowledge for the future

- Optimized SMT program portability

- Valor Parts Library

- Increased efficiency with intelligent line utilization

- NPI acceleration

- Process documentation guidelines template

- Set and maintain DFT guidelines

- Single process engineering solution

Benefits of Valor Process Preparation

- Increases engineering efficiency by using a single tool for all process engineering tasks

- Eliminates preparation work with auto-generation (AG) machine component libraries

- Increases work instruction authoring (documentation) efficiency through automation and use of templates

- Maximizes offline preparation to eliminate online trial-and-error delays

- Preserves manufacturing know-how, including manufacturing best practices, libraries and customer data preparation flows

- Increases product portability by seamlessly moving production between lines and factories using portable production data

- Reduces inspection programming times with comprehensive and accurate component model outputs

Vietbay, an authorized distributor of Siemens EDA and a comprehensive strategic partner of Siemens DISW in Vietnam, is proud to be the coordinating unit to organize this important event. With more than 20 years of experience in the field of consulting, providing, and training technology transfer, Vietbay is committed to providing comprehensive IC and PCB design and manufacturing solutions with services and added value. From there, Vietbay helps customers master technology, develop quickly and sustainably in the digital age.

Read more:

Valor NPI Manufacturing Solutions

Valor NPI Software – Optimize PCB Design, Assembly & Testing

Contact us for free and detailed advice