Collaborative Engineering

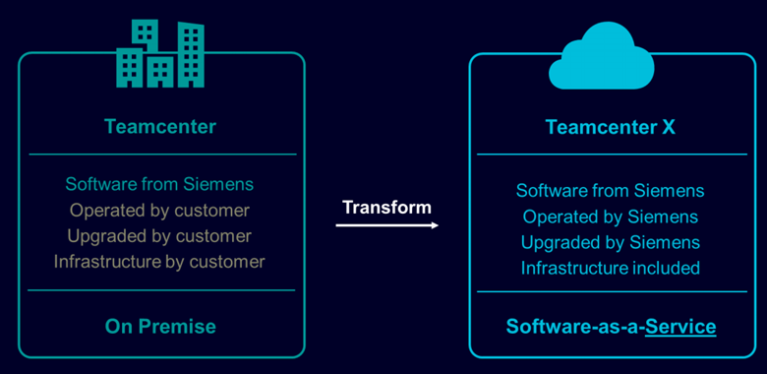

Today’s products are changing faster than ever before, and innovations and technologies continuously drive and accelerate those changes. Smarter, connected, adaptable products are far more complex to design, engineer and manufacture, and require a collaborative engineering approach to be successful. Too often, members of a product team are segregated by tools and software, increasing risk, errors, and frustration. A seamless, data-driven digital transformation can enable and accelerate how companies create products that fundamentally change our lives.An integrated PLM system enables users to collaborate on all product data, including specification, intellectual property, validation, and verification information. With all electrical, mechanical, software, design, and manufacturing activities they increase efficiency and productivity. The result is a robust collaborative environment powered by a single source of truth that enables teams to get the product right the first time.

Digitally Transform Your Business with Collaborative Engineering Tools

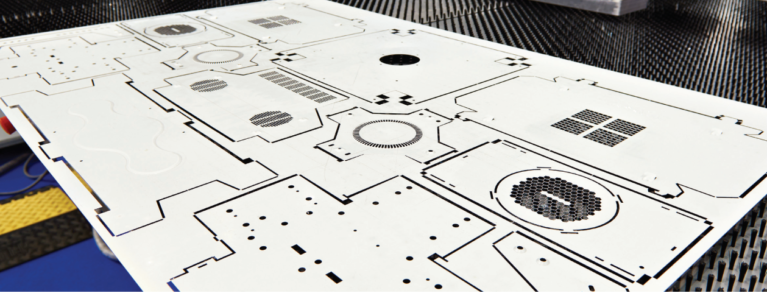

Today’s electronic devices are a synthesis of multiple designs—mechanical, electrical, electronics, embedded software, and application software. Many hardware features remain unexplored and undermanaged because of rapid development, resulting in sub-optimal integration between hardware and software. The disadvantages of operating in different single-discipline platforms and the increasing role of global suppliers in the early stages of design drive engineering organizations to invest in multi-domain integration strategies to ensure the system works flawlessly.

Benefit From a Robust Collaborative Environment

All electronics companies including; Industrial, consumer, and electronics manufacturing service (EMS) companies of all sizes can benefit from a multi-disciplinary approach to engineering lifecycle management that leverages integrated requirements management, secure supplier collaboration, and a single harmonized design, verification and testing environment across multiple engineering platforms. It allows you to find issues as early as possible in the design lifecycle of the system while providing industry-leading performance and platform scalability.

The Benefits of Electronics Lifecycle Management

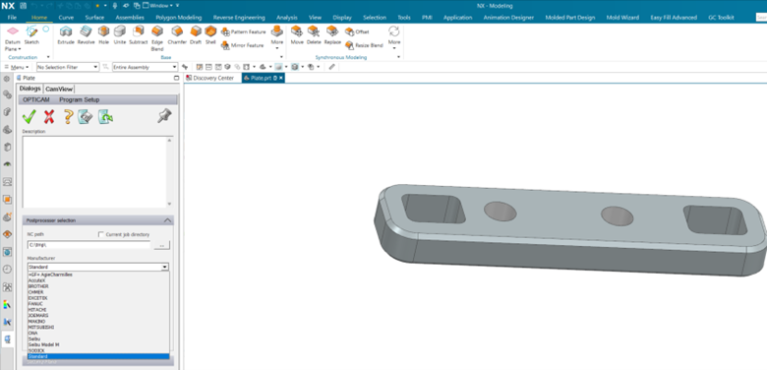

An integrated PLM system that includes application lifecycle management (ALM) enables users to collaborate on all product data, including specification, intellectual property, validation, verification information. With all electrical, mechanical, software, design, and manufacturing activities, they increase efficiency and productivity. Also, electronics companies must maintain efficient ECAD/MCAD co-design and collaboration between the ECAD and MCAD domains to optimize electronics designs within tight form-factor constraints while still meeting quality, reliability, and performance requirements. The result is a robust collaborative environment powered by a single source of truth that enables teams to get the product right the first time:

- Reduced redundancy and data entry

- Reduced design re-spins

- Higher probability of design success

Electronics businesses of all sizes need integrated lifecycle management as their core of digital transformation. To innovate by leveraging the industry’s most comprehensive digital twin.

(Sources: Siemens)

For more information, please contact:

Vietbay CAD/CAM/CAE/PLM Team

Phone/Zalo/Whatsapp: 091 929 5520

Email: [email protected]

Website: www.vietbay.com.vn * www.cadcamcae.vn * www.vietbay.edu.vn