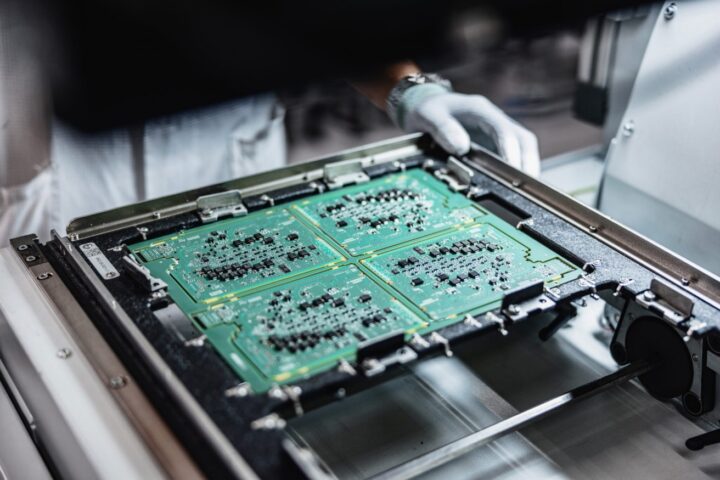

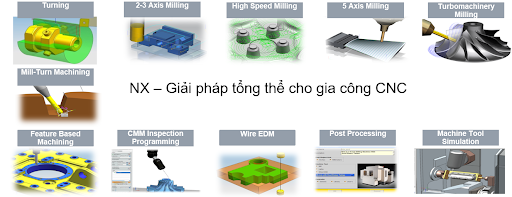

Siemens NX CAM is a CNC machining solution that is being used very popularly today in the world and in Vietnam also. This is a comprehensive CAM programming solution from 2.5-axis to 5-axis machining, machining programming for robots, lathe, Mill-turn, wire-cutting machining, 3D printing… NX CAM integrated with NX CAD – powerful design and editing tools which empower NX is the most powerful software today and chosen by many enterprises who are from various industries of automotive, electronic and semiconductor, consumer products etc.

The advantage of Siemens NX CAM

How does NX software help you make better parts faster? What NX advantages make part manufacturing more productive?

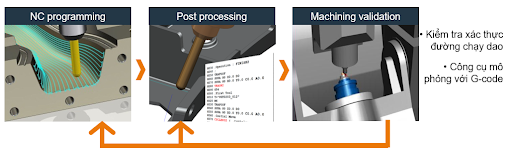

Siemens NX CAM delivers real differences through key capabilities such as its advanced programming, postprocessing and simulation functionality with NC code.

NX provides a complete set of NC programming capabilities in a single CAM system as well as integrating a suite of other applications for manufacturing. Those applications are product design, mold design, measurement programming … all on the same common platform of NX.

Siemens NX has been adopted across a wide range of industries, delivering proven capabilities for manufacturing in aerospace, automotive engines, medical devices, molds and machine components… NX is also suitable for all types of businesses from small workshops with a few CNC machines to large factories with many CNC machines.

When the right design and manufacturing software is matched with the latest controllers, machine tools and other shop floor equipment, you can implement a process chain that delivers maximum performance for your business. Siemens is an established leader in advanced machine tool controller technology and drive equipment. This combination of software and manufacturing equipment expertise enables us to develop part manufacturing solutions that provide you with unique and powerful advantages

Key Capabilities in NX CAM

Advanced programming capabilities

NX provides comprehensive and flexible total capabilities for all your CNC machining needs from simple to complex including:

- 2.5-axis, 3-axis machining: With high-speed manufacturing (HSM), optimize roughing with Adaptive machining toolpath strategies, create finish toolpaths with synchronized strategies streamline toopath, auto-computing inheritance of machining residuals for semi-finishing operations, flexible toolpath strategies with fast toolpath creation time. NX CAM also includes federate optimization that improves machining productivit

- Multiaxis programing: NX CAM Multiaxis provides powerful multi-axis programming with flexible toolpath creation features, easy tool direction adjustment and control, machining simulation with virtual modeling of the combined machining center with NC code program allows to reduce risks in machining, especially in complex machining centers

- In addition to the ability to program milling machining, NX also fully supports programming tools for machining centers for turning, wire cutting, programming for CMM machine, 3D printing or even for machining robots

Programing automation

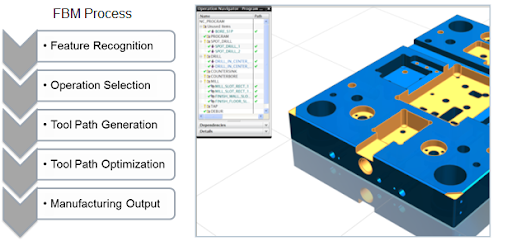

- Automating machining programming with feature base: Including the automatic programming functions of machining for feature base geometry such as holes, grooves, etc., through the feature base function module to reduce 33% up to 60% of programming time. Ability to integrate with PMI to automatically generate machining programs to the required tolerances

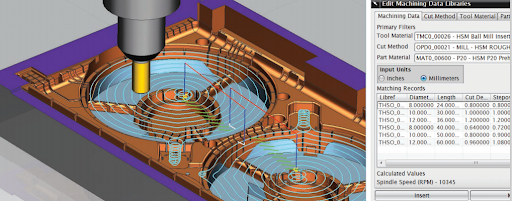

- Create and reuse a machining library data: The Machining data library function allows creating and reusing a library of cutting modes in accordance with the machining standards of each enterprise, minimizing errors and training new engineer during use, optimizing the cutting mode according to the appropriate cutting mode. proven fusion

- Support to create a template to perform automatic machining programming for the same parts repeatedly

- Create and reuse tools library: can create tool libraries in different ways that suit the requirements and usage habits of engineers

- Create sequence machining programs through Machining wizards

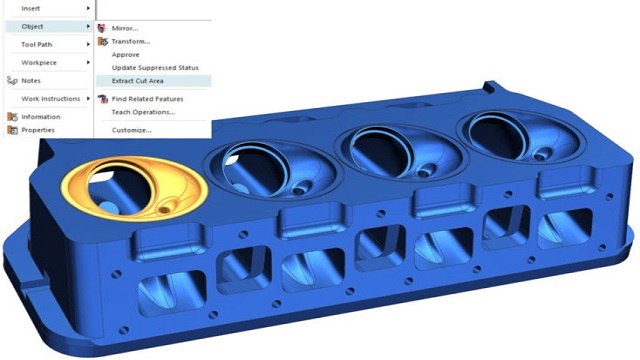

Post processor and machine simulation with NC code

Siemens NX has built-in libraries and applications that help users to reuse or create new post processors that are compatible with most types of CNC controllers such as Siemens. Fanuc, Haidenhai, Okuma, Professional, … NX CAM also provides post processor optimization for the Siemens Sinumerik controller

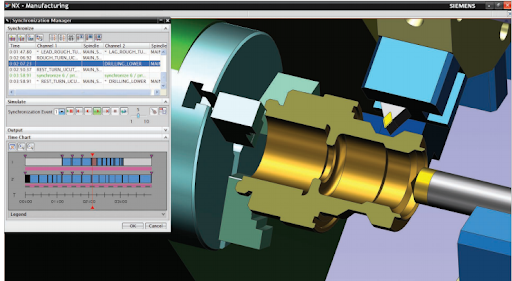

Siemens NX CAM provides the ability to simulate machining with CNC machine model and NC Code instead of simulation with toolpath like other CAM software, which makes CAM machining process safer and more accurate. This process is implemented as the use of a digital copy of the CNC machine on NX CAM, allowing simulation and evaluation before actual machining, helping to reduce machining risks, especially in complex product machining and high expenses

Ease of use

Intuitive interface, allowing users to interact on the graphic screen, easily select, display and adjust tools. Programming productivity can be increased through creating process-specific technical interfaces for new users. Easy program management in a variety of ways, allowing access and management of machining programs.

Integrated and comprehensive solution

Siemens NX includes a comprehensive integrated solution that helps businesses solve all business requirements on a single software platform. With the integration of CAD design environment, programmers can actively edit, reduce or add auxiliary geometric components for the machining programming process. At the same time, it is also possible to expand other applications including jig design, molds, CMM measurement programming, integrated product life cycle management ….

Benefits for businesses

- Improve product quality through flexible, highly customizable toolpath strategies

- Increase machining productivity through high-speed machining strategy with adaptive machining toolpath

- Speed up machining programming with proven automation, library reuse, and process programming tools

- Safety with the machining system by simulating and evaluating the machining program

- Comprehensive CAD/CAM/CAE/PLM extensive integration to suit all business needs with the same single software platform.

Please take a look of NX CAM at the video: https://youtu.be/M8HjvEvAi8c

|

Vietbay has consulted, provide software licenses and training NX CAM for a hundred of customers in Vietnam that such as: 5 axis for Honda Việt Nam, Nakashima (Japan), Intop (Korea), Cosmos và Foshan (Vietnam) , Ha Noi University of Industry; for basic programing of 2.5-3 axis for Samsung companies, Jangwontech, Daegwang (Korea), Foster Electric (Japan)… All customers are happy with the solution as well as Vietbay services. Contact us for further information and support: Mobile/Whatsapp/Zalo: 091 929 5525 (Sales) – 091 929 5520 (Tech)* Email: [email protected]; Website: www.cadcamcae.vn ; www.vietbay.com.vn; www.vietbay.edu.vn |