Variant management in the PCB design process with PADS Professional Premium software. It’s typical for today’s electronic products to have different producible versions or variants. This is because a product may need to change based on where it is being sold – different regions of the world have specific requirements and standards that must be adhered to.

The product may also be changed slightly to meet specific price points. Regardless, this means that a differently populated printed circuit board core design, or variant, for each of these instances is required. The ability to easily make these kinds of modifications, and manage them, is an important part of your electronic design process.

Let’s find out with Vietbay below!

Integrated variant management

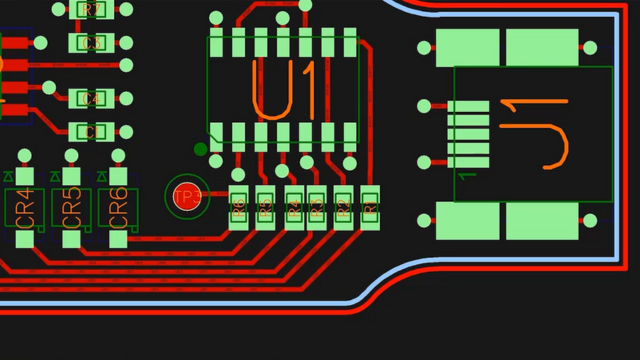

Variant management and definition must be driven from the schematic, and tightly integrated with layout, where a change or modification made is automatically updated in the layout. Once multiple variants are created, if a change is made to the core design, this must instantly update all variants as well.

Core capabilities of variant management should include the ability to define as many variants as you need, with the ability to substitute, remove, or add different components. While hardware engineering is searching for part substitutions during schematic creation, the PCB design tool should have the intelligence that only package equivalent parts are available for selection.

Documentation that supports variant management

Required documentation, such as the bill of materials (BOM), should be easy to create for each variant. The automatic generation of BOMs from the variant management tool eliminates the error prone process of managing variants via spreadsheets – the traditional way of handling variants. In addition, the ability to do a comparison of BOMs between variants should be created to simplify reviews and verification.

The creation of all final documentation should be easy. For the front-end, the required documents include:

- Unique bill of materials

- PDF files of the schematic

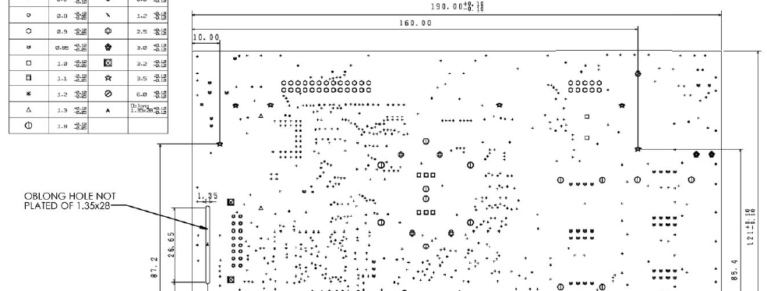

On the layout side, each variant would need unique manufacturing outputs such as:

- Assembly drawings

- Placement information for assembly

- Final artwork or ODB++ files for fabrication

Variant management with PADS Professional Premium

PADS Professional Premium’s Variant Manager delivers this and much more. If you’re looking to increase the efficiency in your design process regarding variants, take a deeper look into PADS Professional Premium by contacting us for free and detailed advice.

Source: Siemens