Leonardo utilizes Xpedition, HyperLynx, and Valor to create complex electronic systems for military and civilian applications.

About Leonardo

Leonardo, based in Rome, Italy, serves a wide range of clients, including private companies, public organizations, governments, and the military. The company designs integrated products and systems for use in various environments, such as aerospace, land, naval, and cyberspace. Leonardo invests significantly in advanced technology to ensure that its products, like radars, electro-optical systems, and especially AESA (Active Electronic Scanning Antenna) radars, meet customer requirements.

Challenges in Product Design

Leonardo faces design challenges such as:

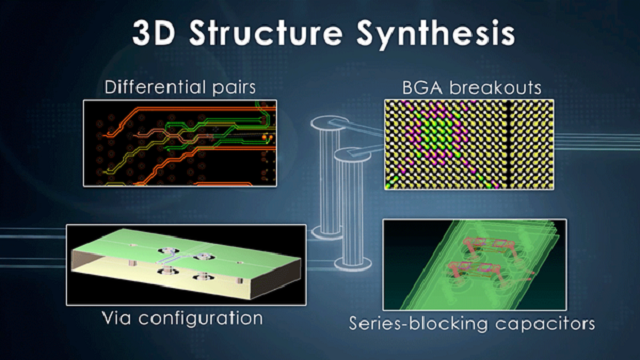

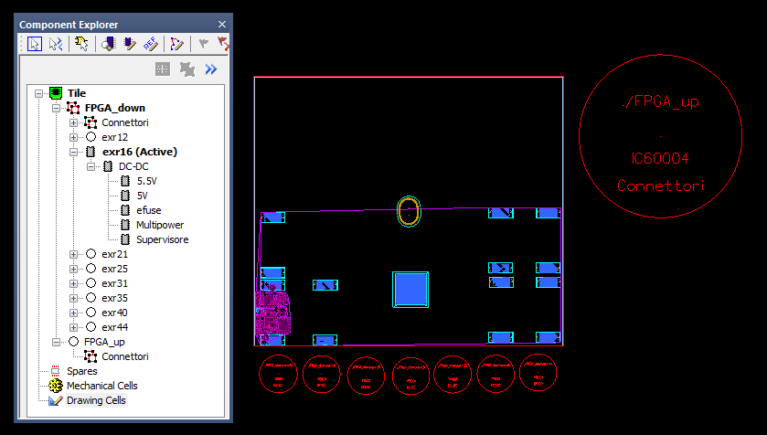

- Performing complex routing for high-speed networks to FPGAs.

- Analyzing signal integrity and ensuring alignment with the design development process.

- Simultaneously analyzing power integrity across layers and decoupling capacitors, as well as verifying boards through thermal analysis.

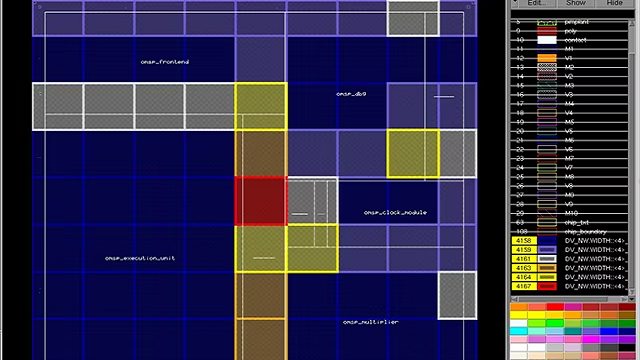

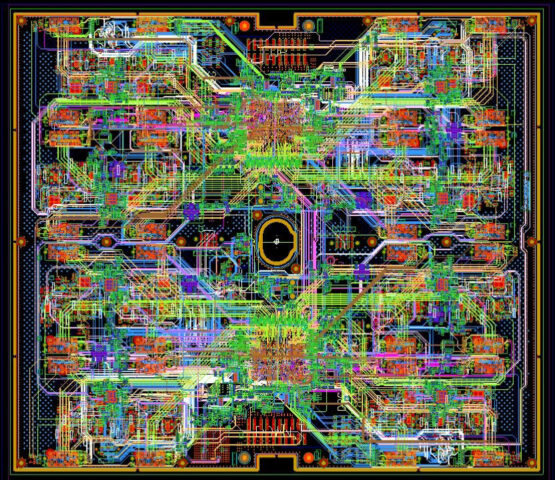

Since Leonardo’s products include many complex boards with programmable digital devices and high-efficiency DC/DC converters, each board typically has 14 to 22 layers, with board sizes ranging from 7,200mm² to 106,000mm², and high-speed interfaces up to 5Gbps. The board designs include thousands of connections, using protocols such as SRIO, JESD204, or PCIe.

Siemens Solutions and Results

Leonardo uses tools from Siemens to overcome these challenges. The solutions include:

- Xpedition: Assists Leonardo in performing hierarchical development, enabling the design of the company’s largest and most complex boards in history. The software also supports IP reuse, reducing schematic drawing time by one-third and cutting board layout design time in half.

- HyperLynx: Supports signal integrity (SI) and power integrity (PI) analysis, ensuring the boards align with design requirements. Leonardo uses HyperLynx to create and verify custom design rules (DRC) to keep electrical characteristics under control during routing.

- Valor: Provides design for manufacturability (DFM) checks to ensure that the boards can be produced with the highest quality and efficiency.

Leonardo’s Experience

- Multidisciplinary Collaboration: Leonardo uses concurrent development and performs electro-mechanical and thermal checks at different stages of the design process.

- Meeting Time Objectives: To meet time objectives, Leonardo implements clear planning and performs simulations and checks throughout the design process. This enables Leonardo to complete complex boards without requiring multiple revisions.

- Reduction in Design Revisions: Thanks to the use of Siemens tools, Leonardo has significantly reduced the number of design adjustments, from 2-3 previous iterations to completing designs on the first try.

The Future of Leonardo

Leonardo plans to continue developing thermal analysis tools and FPGA I/O optimization at a technical level, using Siemens tools to further optimize its design and manufacturing processes.

Conclusion

The use of advanced tools like Xpedition, HyperLynx, and Valor has enabled Leonardo to create advanced products that ensure high quality, withstand harsh working environments, and meet the high technical requirements of their customers. This positions Leonardo as a leader in the aerospace and defense sectors, while maintaining a competitive edge in the industry.

Read more:

Contact us for free and detailed advice: