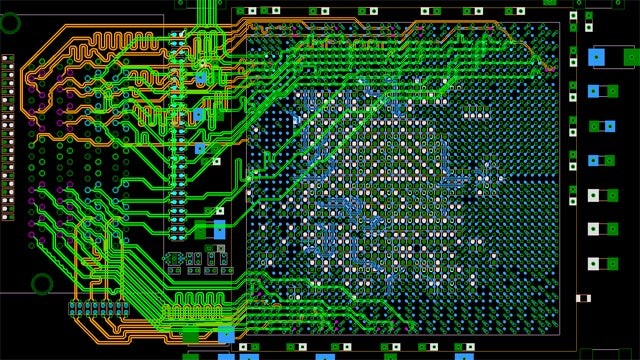

Xpedition Enterprise is the industry’s most innovative PCB design flow, providing integration from system design definition to manufacturing execution. Its unique technologies can reduce design cycles by 50 percent or more while significantly improving overall quality and resource efficiency.

Multi-Discipline Systems engineering

Xpedition delivers integrated, collaborative, co-design systems connecting IC packaging, multi-board, RF, harness, FPGA and MCAD to ensure teams have the flexibility and intuitive technologies they need:

- Multi-Board design: The Xpedition multi-board systems design flow is a fully-parallel, collaborative design environment where global teams can work on the same design in real-time, providing the flexibility and intuitive technologies to develop innovative and competitive products

- ECAD/MCAD Co-Design: Efficient collaboration between ECAD and MCAD domains enables both to optimize their electronics designs within tight form-factor constraints while still meeting quality, reliability, and performance requirements

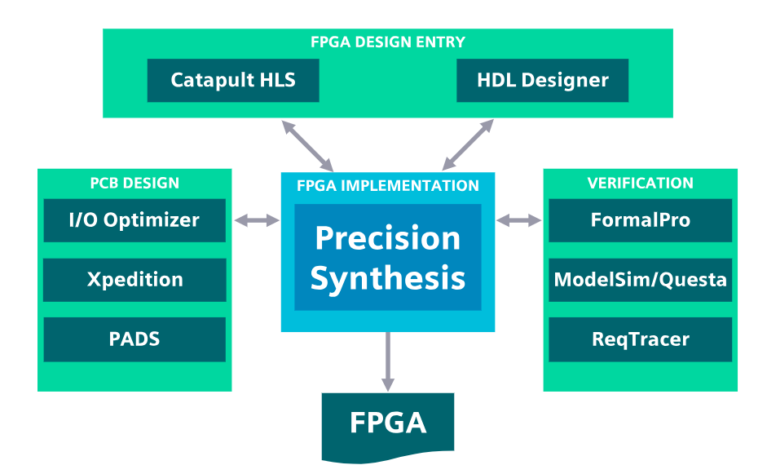

- FPGA/PCB Co-Design: Xpedition I/O optimization technology provides an extensive set of functionality to ease the FPGA-on-board integration process

- IC packaging design & verification: Monolithic scaling limitations drive the growth of 2.5/3D multi-chiplet, heterogeneous integration that enables PPA targets to be met. Our integrated flow addresses prototyping challenges to signoff for FOWLP, 2.5/3D IC, and other emerging integration technologies

- A/D/RF Co-Design: Context with the rest of the PCB. Engineers can enter schematics, optimize layout, and prepare for manufacturing when designing with RF circuits. Integrations with external RF design and analysis tools ensure RF circuit quality

- PCB/Harness Co-Design: Ensure accurate connectivity in systems interconnected via cables by co-designing them with the multi-board hardware. Optimize cabling to ensure optimal performance of the complete system

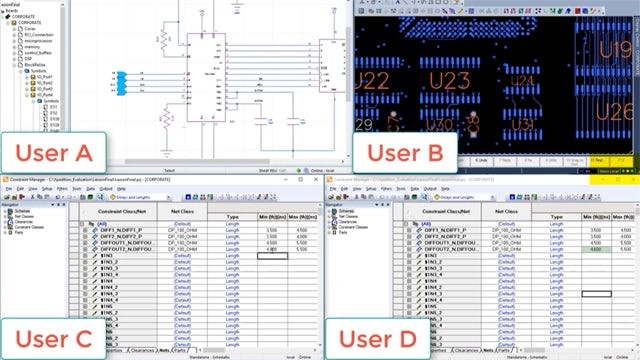

Concurrent Design

Xpedition supports multi-user, multi-site, tool and flow based concurrent engineering throughout the product development process, helping teams dramatically reduce design cycles and improve product quality

- Concurrent Schematic and Layout: Xpedition supports multi-user, multi-site tool based and flow based concurrent engineering throughout the product development process

- System Design Concurrency: Concurrently define a multi-board system with multiple engineers and start defining individual associated boards while the system definition is still in process

- Concurrent Verification: Virtually prototype a design in-process with concurrent verification of performance and manufacturability. Results are visible within the authoring tool for faster review and design updates

Process Automation

Xpedition combines ease-of-use and highly automated functionality to deliver industry-leading advanced technologies for creating today’s most complex PCB designs

- Connectivity Planning and Routing: Powerful automated routing technology enables extraordinary efficiency during PCB layout. Achieve high completion rates while maintaining quality. Automatically unravel complicated net paths and pin escapes to minimize net lengths and quickly and easily identify the best routing strategies

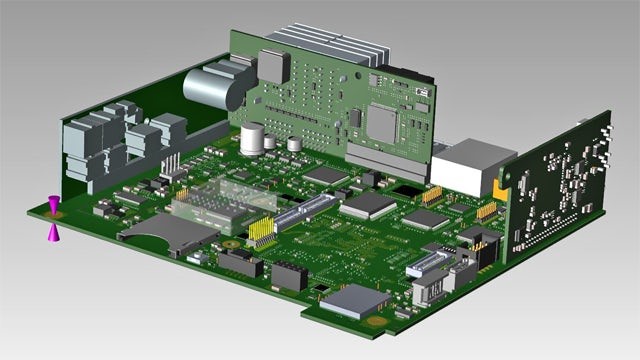

- Component Planning & Placement: 3D component planning and placement provides correct-by-construction placement while taking into account electro-mechanical constraints

- Flow Scalability: Add technology to address product, organizational and process complexity challenges as your needs increase over time

Design Data Integrity

Xpedition engineering data management facilitates the creation and management of engineering components, library, and design data to ensure quality, integrity, and security at all stages of product development

- Managed Design ReuseXpedition EDM facilitates design reuse through enterprise-wide data management of reusable circuit blocks from both the library and design perspectives. Reusable circuit blocks provide teams with an efficient process to leverage a library of ‘certified’ circuitry during new product development

- Model-Driven Part Creation: A powerful component and ECAD library management solution helps librarians speed up the process of researching and selecting parts

- Library Management: Leverage a central library to manage all aspects of the logical to physical part data required in complex PCB systems. The library management solution is scalable, supporting simpler requirements for smaller companies, up to more complex requirements incorporating full component management

- Design Data Management: Integrate and manage Xpedition design data through the entire PCB design lifecycle

- PLM Integration: Manage access and security in each step of the design release process to avoid costly risks

- Web-based Design Review: Optimize collaboration across the larger enterprise with a web-based platform that increases management visibility into projects and facilitates design reviews

Design Verification

Xpedition performs verification during design to ensure zero-spin products while optimizing designs for performance and manufacturability, increasing product quality, and reducing design errors and rework for a more efficient, speedier flow

Schematic Analysis: Xpedition schematic analysis fully inspects all nets on a schematic using an extensive, intelligent model component library and supports performing schematic analysis in parallel with design capture

Vietbay CAD/CAM/CAE/PLM Team

Phone/Zalo/Whatsapp: 091 929 5520

Email: [email protected]

Website: www.vietbay.com.vn * www.cadcamcae.vn * www.vietbay.edu.vn