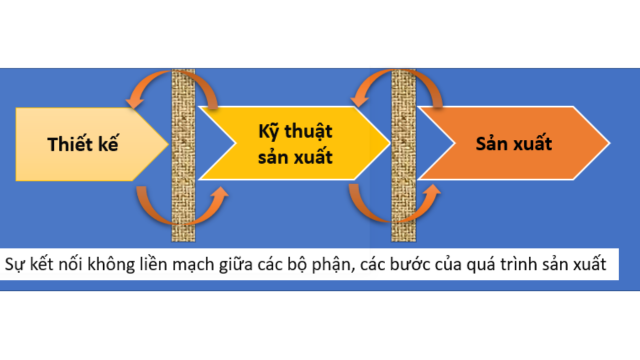

Why PLM in manufacturing? In the globally connected world of manufacturing, keeping information up-to-date and in sync throughout the product lifecycle—from design to manufacturing planning, to the factory floor, to maintenance – is a constant challenge for manufacturers.

Join Vietbay to learn detailed information about SaaS PLM below!

PLM in Manufacturing

Without efficient data management, communication of changes, and collaboration between domains and throughout the supply chain, your business could be at risk. Product lifecycle management (PLM) can help.

PLM, of course, is not new. The technology has been around for quite a while now, and it is a key driver of digitalization and market success for product developers and manufacturers. The benefits to PLM are clear. However, for many product manufacturers, deploying a PLM solution that must cross-over multiple domains and locations, could seem to be a daunting and expensive task, something they may feel is out of reach.

What’s Changed?

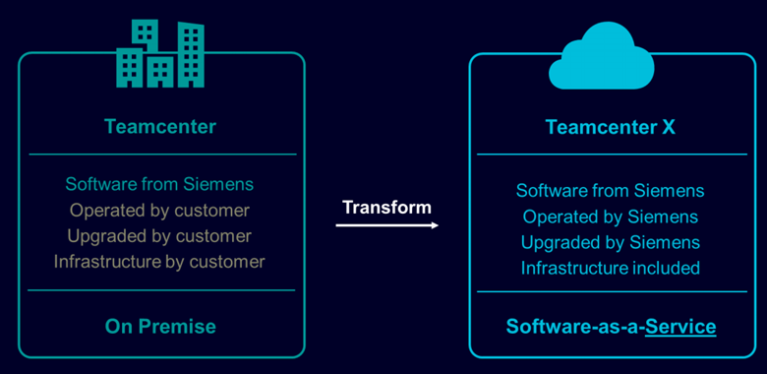

A modern, comprehensive PLM solution that can address tough manufacturing challenges, without the time and expense required to deploy it, and get users up and running fast, has arrived. Imagine the value of PLM realized in days, vs. months, with an easy-to-use, cloud environment with years of manufacturing and industry best practices built into it. Watch this video to learn about the latest addition to the Siemens SaaS PLM offering.

Quick-start PLM in Manufacturing

Teamcenter X Manufacturing is an industry-tailored solution with built-in best practices and role-based authoring capabilities, delivered in an optimized and proven cloud environment to help you get started fast.

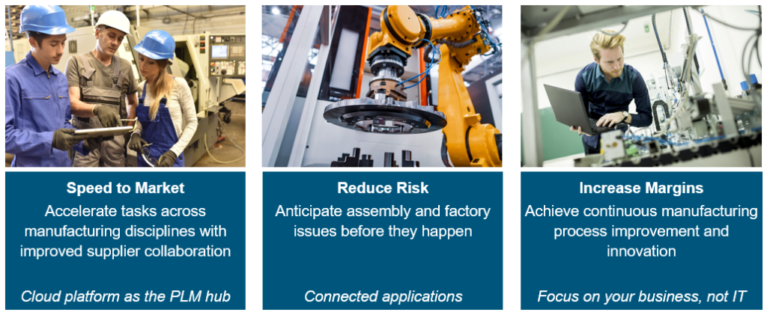

With Teamcenter X Manufacturing, you accelerate time to market by streamlining collaboration across manufacturing disciplines, both internal and external to your organization. You get continuity of data by connecting suppliers and partners in a controlled environment.

You reduce risks by anticipating issues before they happen using proven, integrated manufacturing planning applications. And Siemens does the heavy lifting for you—to reduce your costs and limit your IT resource needs. This lets ‘s you focus on your business for continuous manufacturing process improvement and innovation, leading to increased margins. With Teamcenter X Manufacturing, you can:

- Enable information flow across planning, simulation, and design

- Connect to manufacturing authoring applications

- Collaborate and exchange data with your suppliers and end customers

Source: Siemens

Read more:

- Teamcenter X on Cloud – Top 6 reasons to choose to use product lifecycle management solutions

- What’s new in Teamcenter Quality 2312

- Siemens PLM Data Management Solution – Teamcenter

Contact us for free and detailed advice: