Vericut is one of the world’s leading software for simulating and optimizing CNC machining programs, it is especially useful for the process of verifying the production of highly complex, high-cost parts. or mass-produced products with the desire to optimize machining time as well as tool life.

Last October, CGtech launched a new version of Vericut 9.4 with many improved outstanding features, giving users many useful and optimal experiences. Outstanding new features include the ability to connect to users. Connecting monitoring of the machining process on real machines (CNC Machine Monitoring), improving the simulation component assembly feature (Assembly Manager), improving the tool management tool (Tool Manager), improving the inspection window. Optimize control window, improve the material definition function of machining on the Stock window.

Let’s find out the detailed information with Vietbay below!!!!

1. CNC Machine connect and Monitoring

A new CNC Machine Monitoring module in 9.4 live streams data from CNC machines connected to VERICUT. This connection enables users to monitor current active NC program or subroutine, active NC program line (block), which cutting tool is in use, active tool and work offsets and offset values. CNC Machine Connect’s “Precheck” has a redesigned main window which displays more information and enables users to select more features to get data for CNC Machine Connect licensed users can now run standalone Precheck application from VERICUT. This enables CNC machinists and operators to perform precheck operations before pressing “Cycle Start” on the first part to be run in a new machine setup.

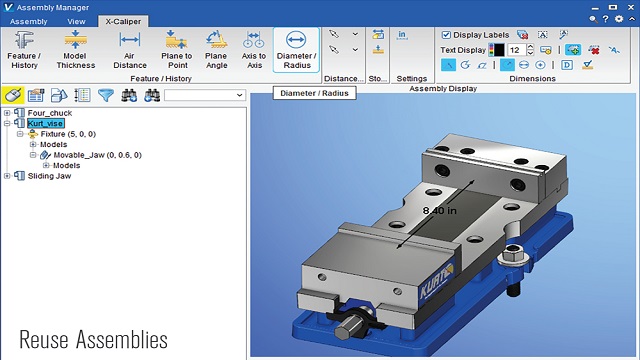

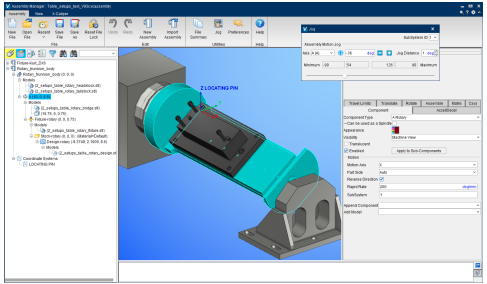

2. Assemnly Manager

The Assembly Manager window has several new features including File Summary button, Jog button (Similar to MDI button in VERICUT), and Preferences button to better utilize Assembly features.

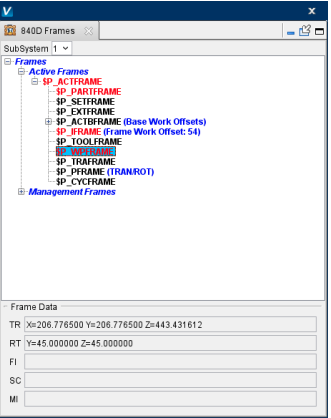

Siemens 840D Control Emulator

VERICUT’s Siemens 840D control emulator has received enhanced support for Frames, TOFRAME and TOROT handling. The 840D Frames window has been completely redesigned to make debugging Siemens Frames even easier. Frames are displayed in a tree format. $P_ACTFRAME is the sum of all Active Frames. Similarly, $P_ACTBFRAME is the sum of all $P_NCBFRAME’s and $P_CHBFRAME’s. For the Management Frames, $P_UIFR, $P_NCBFR, and $P_CHBFR are tables. All entries that are set will be displayed under their corresponding variable name.

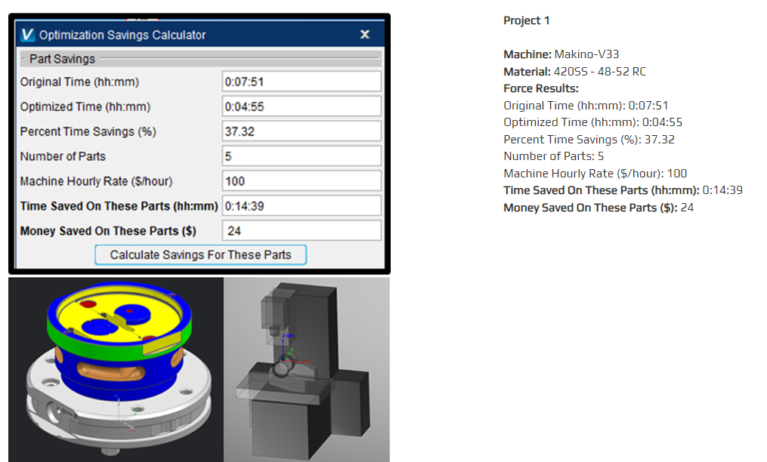

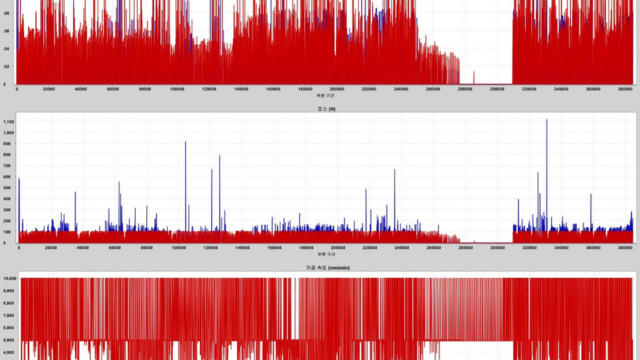

3. Graphs window and Graphs Preferences

The Graphs window has been updated with new features enabling users to toggle cutting conditions, change Graphs display preferences, and show “Peak” or “Average” Force Graph measurements for Force conditions. To see average Force condition graphs, the “Record Average Force Condition” Graphs preference must first be turned on to collect averaged data, as described below.

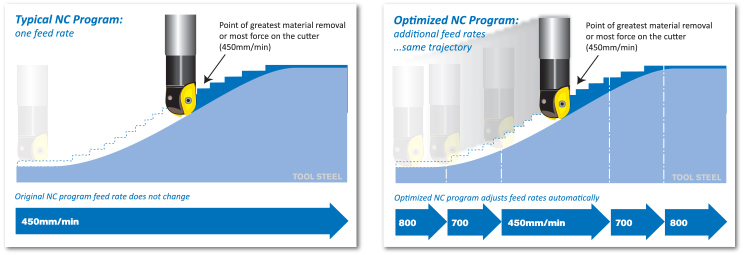

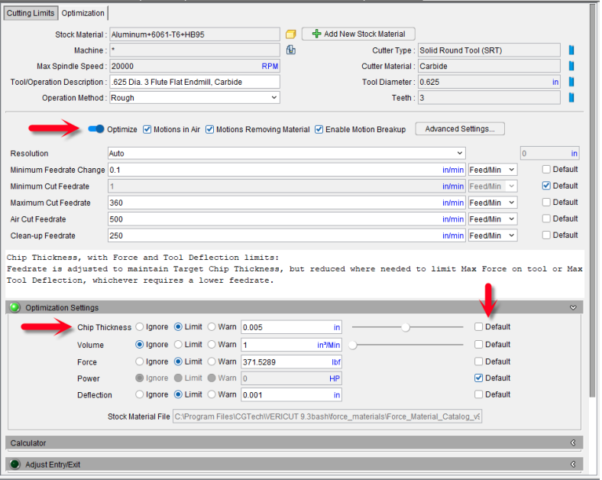

Tool manager

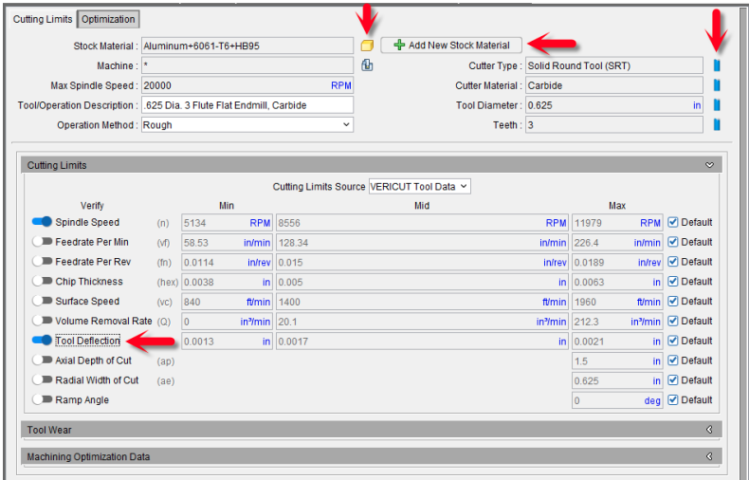

Tool Manager Cutting Limits tab and Optimization tab contain several new features for more granular control of tooling and to improve ease of use. Cutting Limits tab has a Tool Deflection toggle to control deflection during simulation, an Add New Stock Material button to quickly modify the Stock Material Record, and the top panel has been expanded with more information on the tool and materials being used along with an Operation Method to specify whether the simulation should be Rough or Finishing. The Optimization tab has been given an Optimize toggle to activate optimization quickly and easily without opening the Optimize Control window. There are also options to check for Chip Thickness as well as Default checkboxes for all settings to save the positions they have set for their Optimization Settings.

Specifying Stock Material

Stock Material can now be set from the Project Tree, Configure Component: Stock panel. All Stock components use the same stock material so it is only necessary to specify the material for one Stock component. The stock material specification is referenced by VERICUT to generate cutting analytics (e.g., Force conditions), by VERICUT Tool Data to recommend appropriate feeds/speeds and limit ranges, during optimization, and by reports that include the identity of Stock Material from which the part is being made. A Change Stock Material icon () is provided in several locations to guide users to the Project Tree Stock location, such as the Stock Configure Model panel, Optimize Control window, and Stock Material records in VERICUT’s Tool Manager. In prior VERICUT releases these features were only located on the Optimize Control window

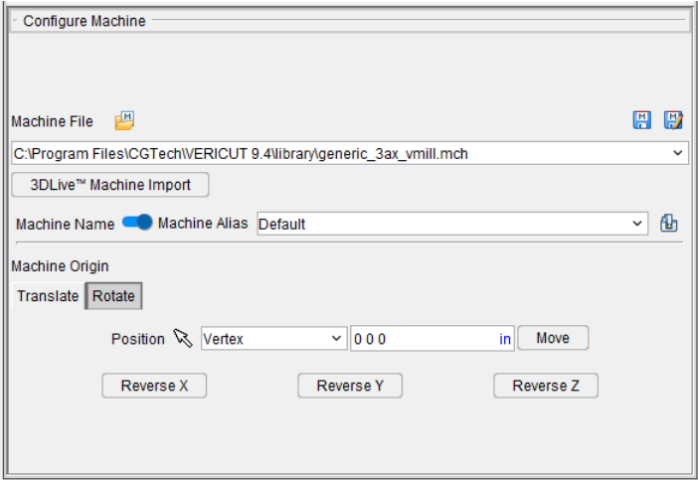

Specifying Machine Name

.The Configure Machine panel has been updated to toggle between the official machine file name and an alias (nickname) you can specify for it. When the toggle is set to “Machine Name”, the Change Machine icon () next to this field enables users to edit the name of the machine specified via the Machine Settings window.

Contact us for free and detailed advice: