In the process of CNC machining, machining engineers and machine operators often encounter many challenging problems such as how to minimize machining time, optimal cutting mode for materials. hard, soft, thin-walled machining, high-cutting hair, increased tool life, poor surface quality, optimized cutting processing by “ears” … Most of the above problems are solved based on the experience of the machining programmer or machine operator.

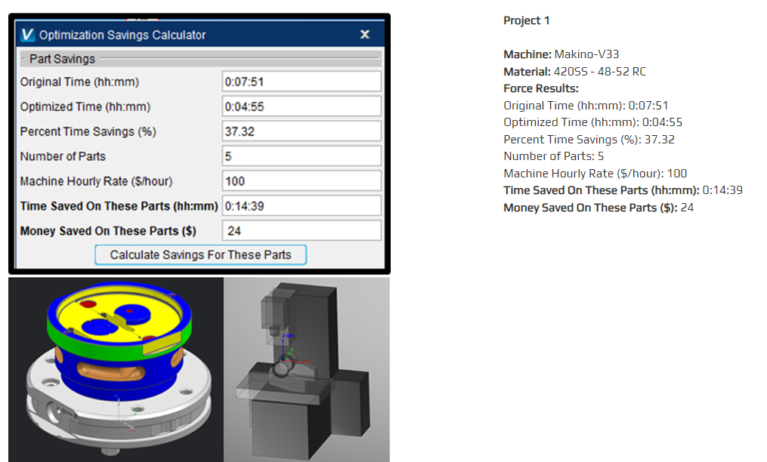

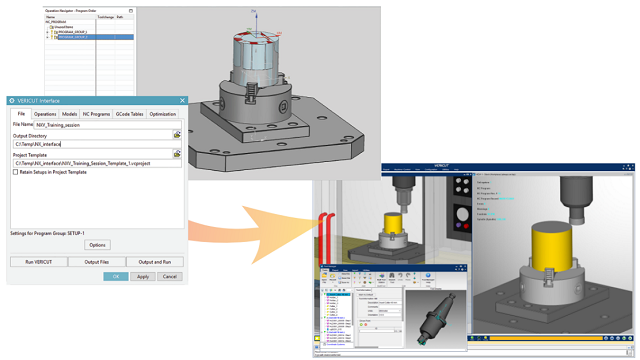

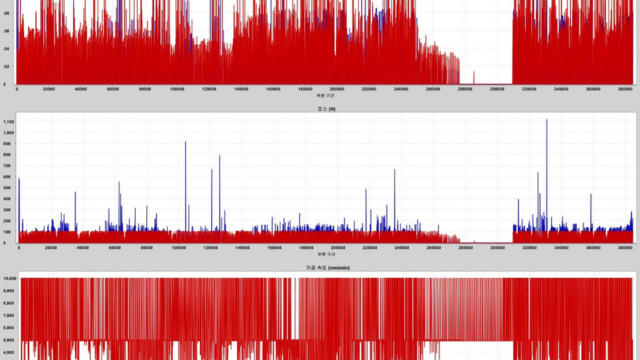

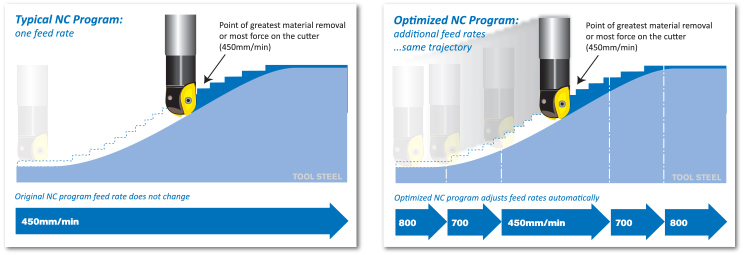

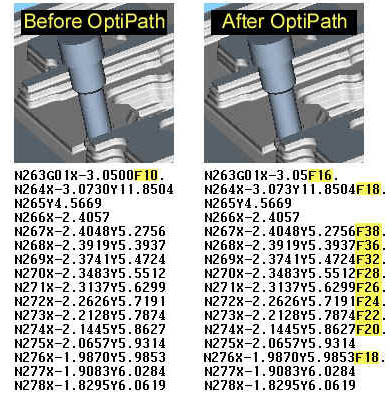

VERICUT is a true knowledge-based machining system: through the simulation process, it learns the exact depth, width, and angle of each cut. And it knows exactly how much material is removed by each cut segment. With that knowledge, OptiPath divides the motion into smaller segments. Where necessary, based on the amount of material removed in each segment, it assigns the best feed rate for each cutting condition encountered. It then outputs a new tool path, identical to the original but with improved feed rates. It does not alter the trajectory.

As the cutting tool encounters more material, feed rates decrease; as less material is removed, the feed rates speed up accordingly. Based on the amount of material removed by each cut segment, OptiPath automatically calculates and inserts improved feed rates where necessary. Without changing the trajectory, OptiPath writes the updated feed rates to a new NC program.

P1. Optimization principle of Vericut optipath

You input ideal feed rates for a number of predetermined machining conditions. OptiPath automatically combines them with factors such as machine tool capacity (horsepower, spindle type, rapid traverse speed, coolant, etc.); fixture and clamp rigidity; and cutting tool type (material, design, number of teeth, length, etc.), to determine optimum feed rate for each segment of each cut. OptiPath also considers factors dependent on the nature of the tool path such as:

● Cut depth

● Volume removal rate

● Entry feed rate

● Cut width

● Cutter wear

● Cut angle

In most CAM programming software, it is not possible to divide toolpaths into small segments and assign corresponding cutting speeds to those toolpaths. Typically CAM software operates on geometry-based toolpath generation in terms of workpieces, tool geometries, and toolpath strategies. The tool speed set on the software is fixed for each program (can adjust the tool engage, retract, some corner running…) but do not subdivide the toolpath to add more speed. individual cutting for each section of the toolpath. With Vericut Optipath helps to add those limitations from CAM software to create the most optimal CNC program. Normally it can reduce product processing time by 12-15%.

Businesses that are necessary and suitable for Vericut Optipath software such as: manufacturing aerospace components, mass processing of automobile and motorcycle components, complex mold processing, … or any other mass production by CNC machine.

For more information, please contact:

Vietbay CAD/CAM/CAE/PLM Team

Phone/Zalo/Whatsapp: 091 929 5520

Email: [email protected]

Website: www.vietbay.com.vn * www.cadcamcae.vn * www.vietbay.edu.vn