The latest version of NX CAM includes automation enhancements and machine-powered programming, enabling faster programming, greater efficiency, and improved part quality.

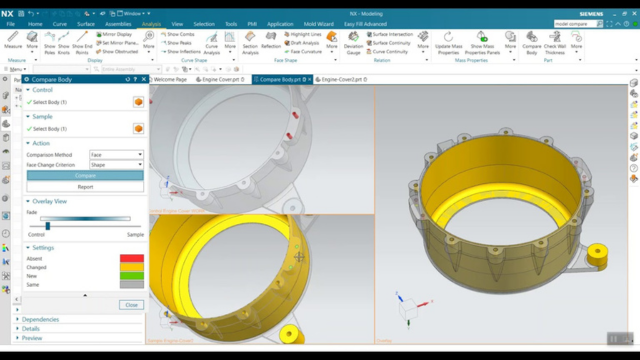

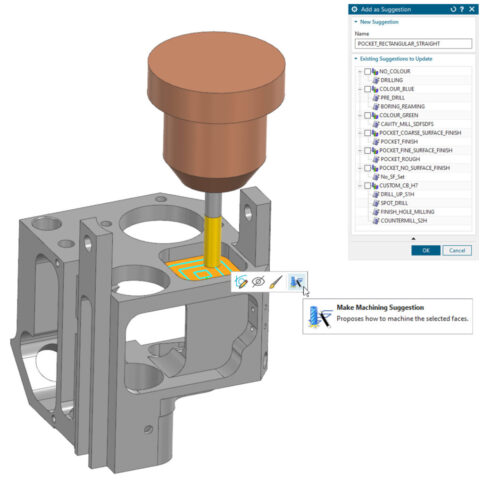

Make Machining Suggestions

Create a complete machining process for a feature with just a click on a component’s face. The latest Make Machining Suggestion feature in NX CAM simplifies toolpath creation, automatically suggesting pre-defined machining processes with an optimized sequence of operations. For example, by selecting the floor face of a pocket you can automatically program the entire pocket using multiple operations and tools.

Additionally, capture your preferences and offer suggestions for future use, helping you program faster, while enabling higher standardization.

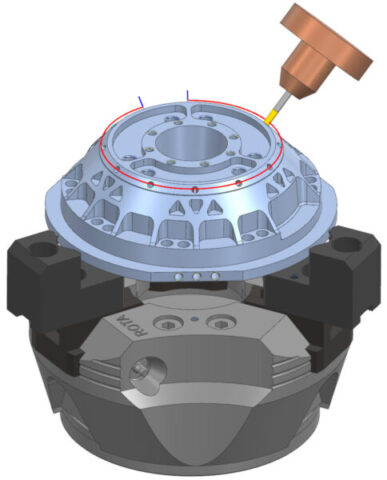

Automatic Hole Machining

Holemaking now includes enhanced automation capabilities. The newly introduced Automatic Holemaking feature allows you to fully utilize the power of Feature-Based Machining (FBM) when programming holes. You can select one or multiple faces with holes and NX automatically detects all holes of various sizes and complexities, groups them, and creates optimized toolpaths to effectively machine them.

Machine Powered Programming

Machine Powered Programming (MPP) integrates machine tool capabilities directly into the programming process. Programmers can use the exact settings and parameters of the selected machine, simplifying the creation of efficient and error-free toolpaths, even for the most challenging multi-axis CNC operations.

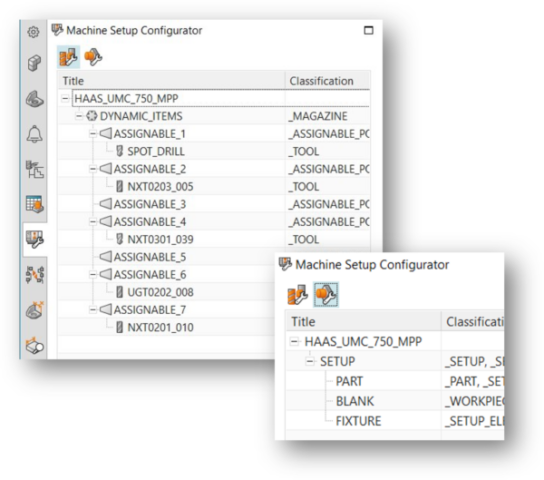

With the new Real Machine Job Commissioning feature in NX CAM, you can efficiently commission tools, devices, parts, and fixtures using an intuitive graphical interface.

The Machine Setup Configurator Navigator transforms commissioning tasks by introducing a dedicated view for part and tool setup.

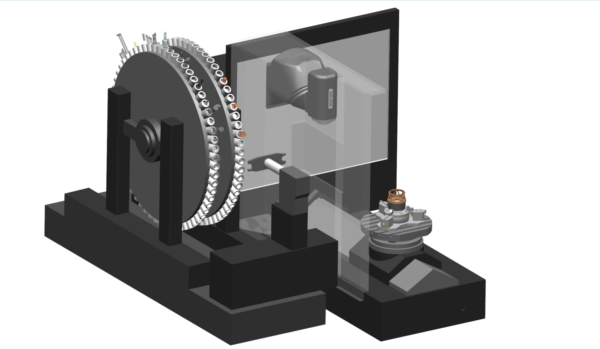

Machines with specified kinematics in the Machine Tool Builder can now be defined with turrets or magazines featuring static pockets. This enhancement ensures that tools are accurately positioned during CAM programming, improving setup efficiency.

With turret support, you can now program lathe machines while fully leveraging all MPP advantages, including the tool-in-machine display functionality, making programming more streamlined and precise than ever.

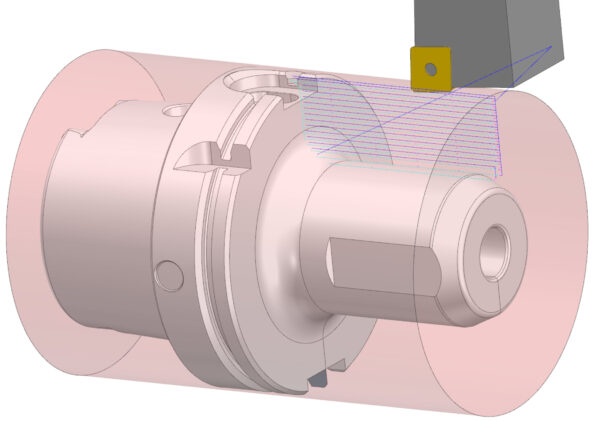

The latest “Display Tool in Machine” feature in NX MPP allows you to verify turning and mill-turn operations with ease. By previewing machine motions during programming, you can optimize toolpaths and prevent collisions. This enhancement supports both single-channel lathes and complex mill-turn machines with B-axis or turn-mill configurations (e.g., DMB FD or Heller CT/CP), with updated axis and kinematics chain definitions in the Machine Tool Builder. With an instant preview for advanced turning technologies like Y-axis turning and dynamic tool orientation, this feature not only streamlines programming and improves accuracy but also enhances overall workflow efficiency by enabling faster verification and optimization of toolpaths while reducing the risk of collisions.

The latest chip breaking option for turning toolpaths provides an efficient solution for managing long, stringy chips during machining. You can now control the tool’s engagement with the workpiece to break chips into smaller, manageable lengths. This improvement enhances chip evacuation, minimizes entanglement, and promotes cleaner machining environments. It also reduces downtime, improves surface finishes, and extends tool life.

These features not only reduce programming and machining time but also enhance accuracy and product quality, meeting the demands of modern manufacturing.

(Source: Siemens)

Video 1: New in NX CAM 2412 – Machining Suggestion Feature

Description: The Make Machining Suggestion feature in NX CAM allows you to complete machining for a feature by simply selecting the part’s surface. Once activated, NX provides predefined machining process variants as out-of-the-box (OOTB) solutions.

Video 2: New in NX CAM 2412 – Machine Setup Configuration in NX CAM

Description:Set up stock and cutting tools using the Machine Setup Configurator. CAM configurations for machine programming enhance productivity and efficiency for CAM programmers by improving consistency.

Video 3: New in NX CAM 2412 – Defining Tool Magazines or Turrets with Machine Powered Programming

Description: Machine Powered Programming now supports tool magazines and turrets with static pockets, defined for machine kinematics in the Machine Tool Builder.

Video 4: New in NX CAM 2412 – Advanced Chip Control in Turning – Chip Breaking Option

Description: Advanced chip control in turning operations enables chip breaking position control to improve process safety, machined surface finish, and product quality.

Video 5: New in NX CAM 2412 – Automatic Hole Machining

Description: Leverage the full power of Feature-Based Machining for simple hole machining without needing to be familiar with the Feature-Based Machining process by using the Automatic Hole Machining feature.

Read more:

- Integrated Data Management With NX X

- Automating Wire EDM Programming with NX CAM Advanced Wire EDM (OptiCAM)

- What’s new in NX: Core Design

Contact us for free and detailed advice: