The latest version of Zel X was released in June and brings a wealth of new features and improvements across operations, manufacturing, collaboration, design and simulation to help businesses and departments of all sizes to achieve greater efficiency and precision in their workflows.

Operations

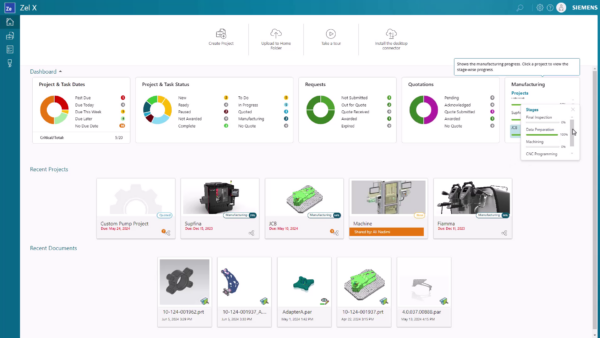

Real-time monitoring capabilities have been added, allowing users to instantly access manufacturing progress and Request for Quote (RFQ) statuses directly from the dashboard. Displayed as tiles at the top of the Zel X dashboard, these additions allow you to stay up to date with live manufacturing statuses and outbound RFQs at a glance.

Design

A new material library lets users to assign physical properties like density and Young’s modulus to models or create custom properties. Material properties can be leveraged in mass calculation, simulations, parts lists, NX collaboration and more. The material library is essential for precise simulations and detailed parts lists. Additionally, new tools for calculating physical properties, such as volume, mass, and inertia, enhance design accuracy.

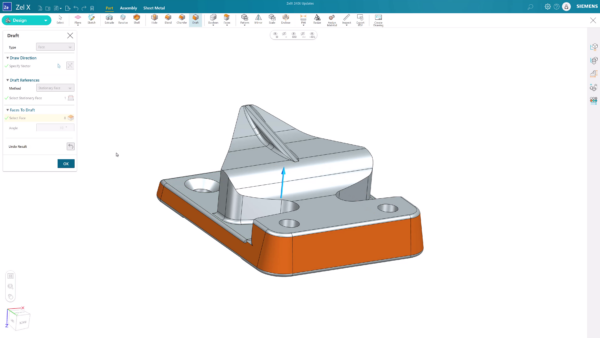

Custom model views and section views have been added, allowing for precise visualization of internal part details, crucial for both manufacturing and drawing applications. Draft features have also been added to allow users to design for injection molding and casting. Draft features allow users to create and edit tapers on faces for easy part removal from molds.

Zel X continues to expand its roster of CAD file types supported for import and edit. New additions for the June 2024 release include, Solid Edge assemblies and STEP parts and assemblies.

Other enhancements and additions to Zel X’s design capabilities include…

- Double-click features or sketches in the tree for fast editing.

- Precisely move and rotate sketch elements with the move handle.

- Easily create copies of sketch elements with a simple Ctrl+ drag operation.

- Edita sketch’s plane including on-the-fly sketch edit.

- Get clear feedback of an under or fully defined sketch through entity color.

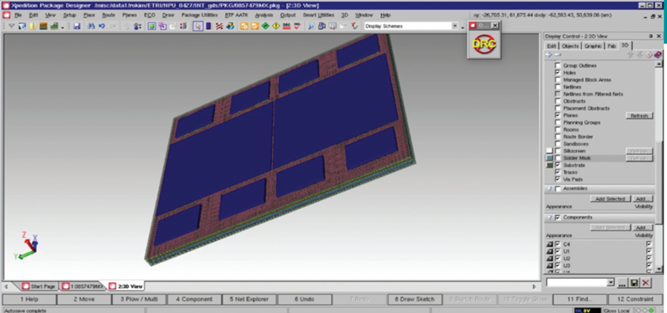

Assemblies

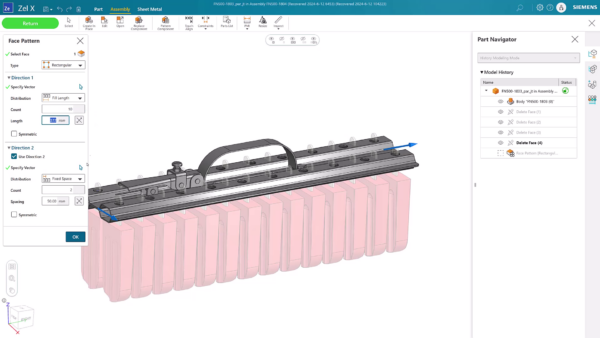

With component replacement, users can replace single, multiple or all instances of a component in a single operation, improving efficiency. Associative pattern enables the use of modeling-level patterns as references to create patterned components. The ability to drag components within an assembly for positioning helps in validating mechanisms and understanding degrees of freedom.

Users can now also create planes, enclose and replace parts in the assembly environment with any level modeling. Edit extrude, revolve and plane commands at any level.

Detailed Drawings

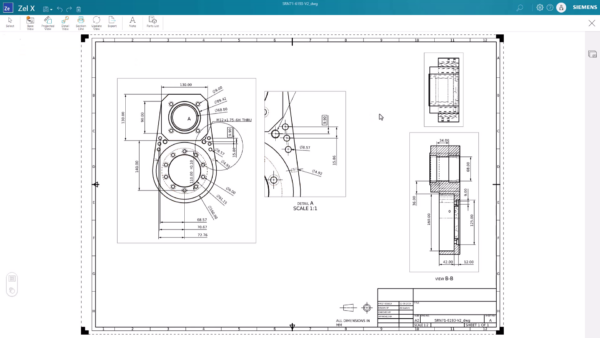

Detailed and section views are now available allowing for better visualization of designs in detailed drawings. Detail views display an enlarged portion of an existing drawing view to illustrate details. Section views created in the model with section lines can be leveraged to visualize and dimension the internal details of parts.

Parts lists of the components in an assembly can now be created and placed anywhere in the drawing sheet.

ANSI or ISO settings can be defined as the default design standard for use in PMI. An administrator can set this for all users of the account. Users can select the design standard or use the default setting when creating a new design.

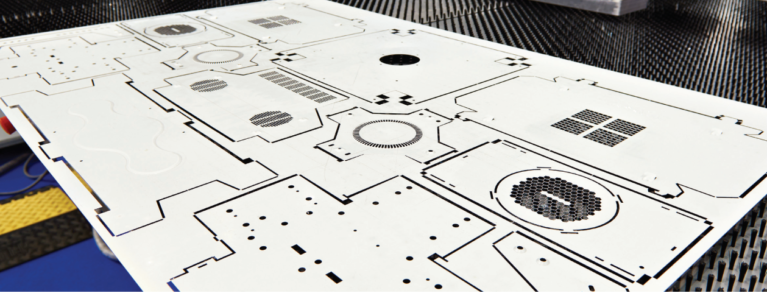

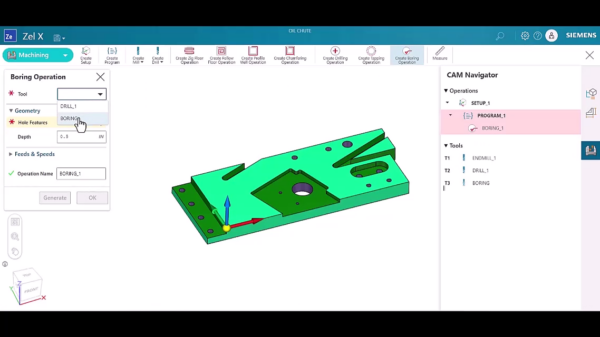

Manufacturing

Manufacturing processes are optimized with the ability to select precise start points for cutting tools in milling operations. Toolpath optimization features reduce stress on cutting tools, extending their lifespan. New chamfer and hole operations streamline editing and selection, improving efficiency in hole-making processes.

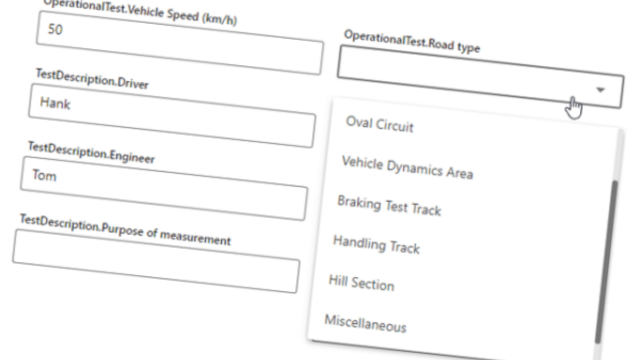

Simulation

New result measure capabilities allow users to extract specific measurements from analysis. The color bar widget has been enhanced and now displays result interpretation in a gradient for easier reading and interpretation.

Collaboration

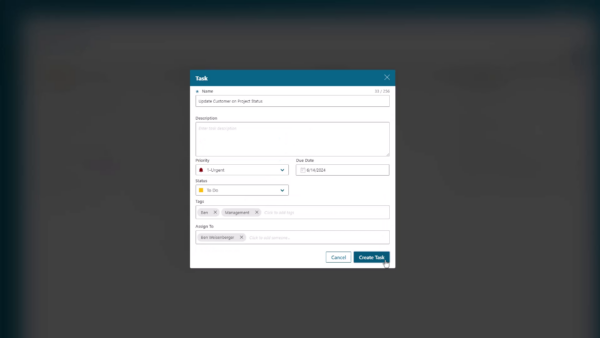

Task tagging and management improvements highlight the June 2024 collaboration enhancements. Tags can be added to tasks for effective filtering, and task cards can be rearranged in Kanban View for personalized management. Enhanced multi-user support provides automated guidance when other users work on CAD models, ensuring seamless collaboration.

The support Solid Edge assemblies, STEP parts and assemblies, and CATIA parts and assemblies, give users the ability to view and markup additional CAD file types.

An all-in-one solution designed for small businesses and departments

Zel X, from Siemens Digital Industries Software, is an integrated collection of tools in a single browser-based app, designed to help smaller businesses and departments improve and consolidate their manufacturing, collaboration, operations, design and simulation processes.

The continuous release cycle of Zel X ensures delivery of those tools and functionalities as soon as possible, allowing small businesses to move faster.

Affordability and scalability

Zel X is offered via cost-effective, tiered subscription plans tailored for small businesses — Zel X Standard and Zel X Advanced. This allows businesses to select the functionalities and capabilities best suited for them and their customers.

Siemens Xcelerator is a comprehensive, integrated portfolio of software, services and application development platform designed to help companies become digital enterprises. Zel X and other cloud-based solutions are available via Siemens Xcelerator as a Service to make digital transformation happen faster.

Built on established Siemens Xcelerator platform technologies, Zel X allows users to easily interact with other companies using Siemens software and allow seamless scalability beyond Zel X. Users can maintain their design data and leverage it across the entirety of the portfolio, including NX Design, NX Manufacturing and Simcenter 3D.

Source: Siemens

Contact us for free and detailed advice