Hanoi University of Industry uses Siemens solutions to improve student education and enrollment while reducing costs

“Leveraging the Siemens Xcelerator business platform, the Smart Factory Research Center became a key development for improving the university’s training quality.”

Dr. Tran Duc Quy, Rector

Hanoi University of Industry

Keeping up with engineering education standards

Established in 1898, Hanoi University of Industry (HaUI) was one of Vietnam’s first technical schools. With a focus on delivering a comprehensive education and supporting Vietnam’s national industrial revolution, the university envisions becoming an institution of applied scientific research and training since many of their students aim for a career in either engineering or manufacturing. This has led the university to continually improve and develop its academic offerings to keep up with industry standards.

HaUI gradually built a series of modern laboratories to provide students with comprehensive, real-world training. For this, the university investigated solutions within the Siemens Xcelerator business platform.

Solving outdated technology limitations

As engineering and manufacturing industries shift toward smart factories and digital software solutions, such as using a digital twin for product development, the university found that graduates needed extensive on-the-job training.

To prepare students for Industry 4.0, the university needed a digital overhaul. Thus, they examined a range of potential digital tools and chose to implement Siemens Digital Industries Software solutions.

The university enlisted Vietbay, a Siemens partner, to collaborate on updating its training laboratories, leveraging their consultation, installation, integration and training services.

Creating the Smart Factory Research Center

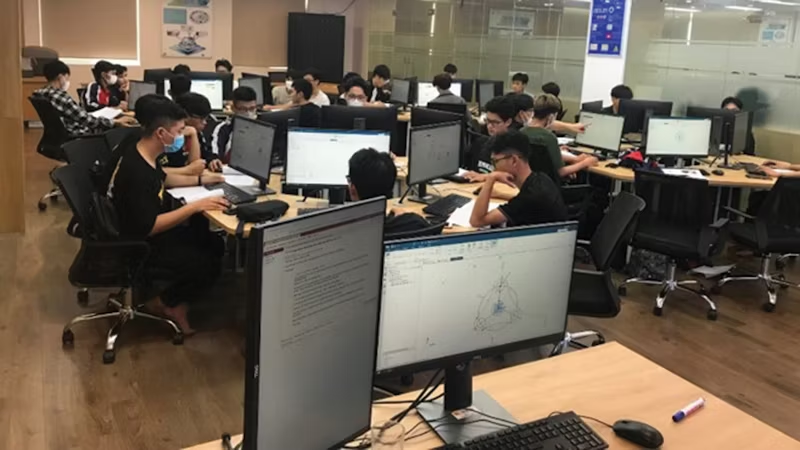

By collaborating with Vietbay, HaUI was able to create the Smart Factory Research Center, which includes five research and practice labs, all connected using the Teamcenter® portfolio. These labs allow students to gain experience in all areas of production before graduation, with each corresponding to a specific product development stage, including research and development (R&D), mold and die, digital manufacturing, basic automation and advanced automation.

One of the biggest challenges was integrating the university’s requirements, such as its 3-axis and 5-axis computer numerical control (CNC) machining centers, with advanced technology. However, leveraging the user-friendly design of Teamcenter and Vietbay’s expertise, they were able to fully onboard the university’s machinery to facilitate information sharing across all production stages.

Vietbay also offered extensive training as part of its support package to the university. This included 40 courses delivered over 170 working days and introductions to tooling design in NX™ software, advanced planning and scheduling (APS) in Opcenter™ APS software, the internet of things (IoT) and low-code programming in the Mendix™ platform and application lifecycle management (ALM) in the Polarion™ portfolio. Teamcenter, NX, Opcenter, Mendix and Polarion are all part of the Siemens Xcelerator business platform of software, hardware and services.

Students and instructors participated in this training, paving the way for future course improvements.

“Leveraging the Siemens Xcelerator business platform, the Smart Factory Research Center became a key development for improving the university’s training quality,” says Dr. Tran Duc Quy, rector at Hanoi University of Industry. “Thanks to Siemens and Vietbay, we can provide thousands of lecturers and students the opportunity to practice using the latest technologies prevalent in Industry 4.0.”

“The Smart Factory Research Center, using the Siemens Xcelerator business platform, provides a powerful set of tools for teaching, researching and training engineering students,” says Hoang Tien Dung, head of the Faculty of Mechanical Engineering.

Digitalizing to improve student education

By collaborating, HaUI and Vietbay were able to revitalize the university’s hands-on training while eliminating the need to invest in new equipment. For example, using 3D computer-aided design (CAD) tools such as NX, students were able to practice using a digital twin without needing access to physical machinery. This shift toward virtual spaces resulted in budget savings of an estimated 15 percent since the university was able to reduce its outlay on electricity and miscellaneous upkeep.

With the Vietbay training courses, combined with increased accessibility to technology, the university expanded its educational offerings to over 200 courses, making use of the Smart Factory Research Center.

“Lecturers are now trained to use the Siemens Xcelerator business platform,” says Trinh Van Long, director of the Smart Factory Research Center at HaUI. “This means educators can access a treasure trove of the most advanced technology currently available for teaching students.”

By improving access to high-quality testing environments and tools, students can pick increasingly complex topics for their graduation theses and essays, reducing the need for post-graduation training. These improvements are also attracting new students, with student enrollment increasing year-over-year (YoY) by 10 percent since finalizing the Smart Factory Research Center.

“Thanks to Siemens and Vietbay, we can provide thousands of lecturers and students the opportunity to practice using the latest technologies prevalent in Industry 4.0.”

Dr. Tran Duc Quy, Rector

Hanoi University of Industry

Source: Siemens