In the dynamic world of engineering, Simcenter Physical Testing solutions support your journey toward engineering success, as they bridge the gap between reality and simulation. Our goal is to help you navigate the complexities of your products, improve the accuracy of simulation models and maximize the efficiency of physical testing.

Our solutions enable the integration of your team’s activities with the broader development organization, ensuring that vital test performance data informs decision-makers and benefits other teams.

Introducing Simcenter Testlab 2306

The year 2023 brings a host of exciting enhancements to both Simcenter Testlab and its next-generation counterpart, Simcenter Testlab Neo. On the data acquisition hardware front, the Simcenter SCADAS RS, designed for rugged environments, now boasts expanded capabilities.

Simcenter Testlab 2306 helps you:

- Model and measure the complexity of your products with the latest advancements on Virtual Prototype Assembly now supporting multi-level assemblies and virtual instrumentation.

- Explore the possibilities of sound evaluation with the Simcenter Testlab NVH Simulator long before a prototype exists and gain deeper insights into the prototype’s acoustic and vibrational responses.

- Enhance your testing and simulation processes through a further refined data management accounting for consistent descriptive annotation and enabling the Desktop efficiency tools also for centralized data.

- Make your measurement campaigns go faster with simplified and automated processes in Simcenter Testlab Neo, streamline instrumentation and remotely acquire data with the latest Simcenter SCADAS RS enhancements.

Innovate your products faster and explore how models accelerate your physical testing processes with Simcenter Testlab 2306.

Check out the video below for an overview of what’s new in the 2306 release: https://youtu.be/hoVCjhtsJYQ?si=R3VAN7Pf0Mecau2t

Vehicle NVH prediction & simulator

Vehicle NVH prediction & simulator

Vehicle NVH prediction

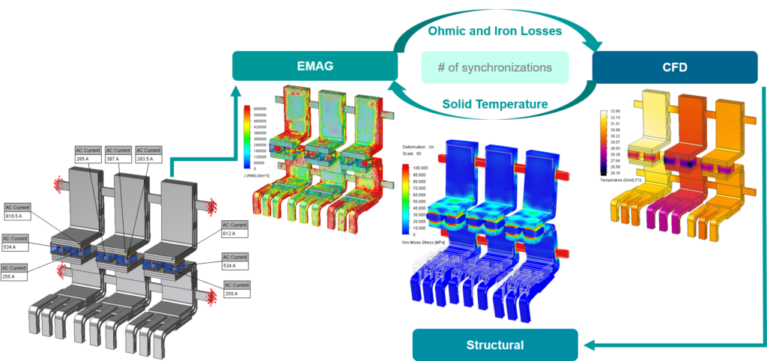

Vehicle NVH prediction is a critical early-stage process for assessing noise and vibration in mechanical systems. Simcenter Testlab Virtual Prototype Assembly offers a virtual system representation, enabling performance prediction prior to physical prototyping.

NVH simulation is often complex due to strong vibro-acoustic coupling among system components, limiting component reusability. Blocked Forces technology overcomes this hurdle, facilitating the reuse of vibro-acoustically characterized components in different configurations. Blocked Force technology demands precise measurements, often in hard-to-reach locations. Utilizing a CAD drawing facilitates sensor placement, enhancing accuracy and reducing errors.

This technology enables system breakdown into reusable components, fostering centralized component libraries accessible to simulation and test teams. Stored in a well-annotated central database, these components become easily shareable among users. Direct access within Simcenter Testlab VPA streamlines full system assembly for efficiency.

Simcenter Testlab NVH Simulator

The 2306 release extends capabilities to predict noise and vibration in complex multi-level assemblies, providing deeper insights. But what about the sound? The Simcenter Testlab NVH Simulator lets you audibly experience your vehicle long before it’s built. Seamless data transfer between the Vehicle NVH Prediction solution and the Simcenter Testlab NVH Simulator in this release allows efficient iteration between component updates and sound evaluation.

Productive NVH performance evaluation

Productive NVH performance evaluation

Productivity in NVH testing

The latest 2306 release brings significant improvements to the collection, processing, and evaluation of operational NVH data, all with a focus on productivity and user-friendliness.

Key features in this release include the ability to edit meta-data to rectify earlier errors and usability enhancements like property-based curve coloring. Simcenter Testlab Process Designer allows for graphical programming and automation of various processes, including specialized scenarios.

Functional extensions encompass the calculation of Hand-Arm and Whole-body vibrations in compliance with ISO norms. Calculated blocks can now serve as input for the calculator and Average Run functions in Simcenter Testlab Neo.

Usability improvements for defining complex processes are also incorporated, ensuring seamless execution on diverse data formats. Process Designer maintains traceability and integrates Audio & Replay functionality for efficient Psycho-acoustic evaluations.

Additionally, the release introduces new psycho-acoustic metrics, real-time order filtering enhancements, and Off-zero filtering to eliminate electric vehicle PWM signatures. FRFs can be used as filters for time data.

Productive workflows

Simcenter Testlab Process Designer now integrates directly with Simcenter Testlab Time Data Acquisition, enabling streamlined data acquisition, processing, visualization, and reporting in a single workflow. This integration saves time and eliminates the need for re-testing.

For SCADAS XS users, a new Event Marker App is available for tablet use, simplifying event marking during recording and annotation for streamlined data processing in the lab.

Scalable and productive collaboration

Scalable and productive collaboration

Efficient collaboration

Efficient data centralization and reuse are top priorities for test engineers seeking to enhance collaboration across departments and development sites. The challenge lies in managing data from various sources and multiple PCs, which often leads to time-wasting data searches.

Simcenter Testlab Data Management, seamlessly integrated into Simcenter Testlab Neo, resolves these issues. The deep integration offers powerful efficiency tools and the same user-friendly experience, whether working with local or centralized ASAM-ODS database data.

Digital thread

Simcenter Testlab also connects to Teamcenter through Teamcenter Simulation, ensuring traceability and relationships between test processes and other product data. This facilitates a seamless digital thread from product definition to physical evaluation.

Additionally, the Simcenter Testlab Desktop supports Teamcenter Share for convenient cloud-based collaboration between OEMs, suppliers, and departments.

Productive testing in harsh environments

Simcenter SCADAS RS 2306

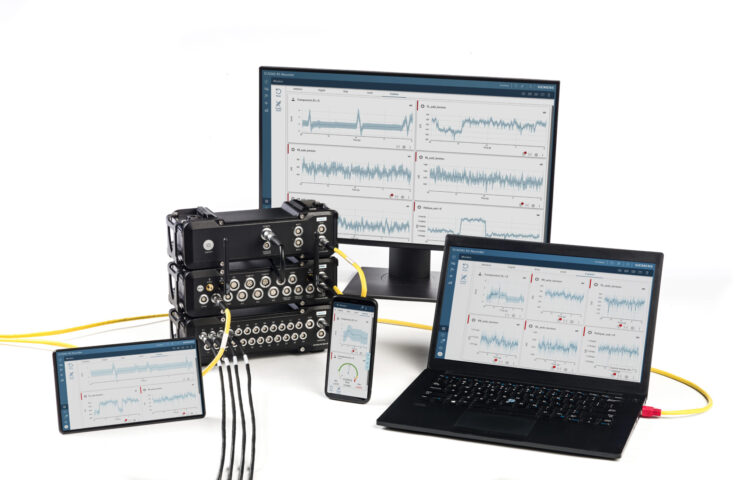

Outdoor testing can be challenging due to harsh environmental conditions. Introduced two years ago, Simcenter SCADAS RS is a rugged data acquisition system built to thrive in these conditions. Its flexibility supports centralized or distributed configurations with various signal conditioning options.

Simcenter SCADAS RS offers remote data acquisition via an embedded web app or the Simcenter Testlab platform, making it ideal for outdoor testing in tough environments. Over time, Siemens has enhanced its capabilities in functionality, reliability, and usability.

Additional modules

In revision 2306, additional modules include the TC20-unit for thermocouple inputs, the DI-unit for CAN, CAN-FD, or XCP inputs, and the ECAT-unit for EtherCAT integration in closed-loop RIG testing. The U12-E-unit with increased bandwidth is suitable for operational NVH data acquisition.

Streamline instrumentation

To streamline instrumentation, the Simcenter SCADAS RS Configuration builder allows offline configuration creation, keeping hardware available for other users. Simcenter Testlab Neo introduces scope functionality for setup validation, enhancing efficiency.

For off-highway equipment testing, Siemens offers an autonomous data acquisition solution. Data is offloaded in the field via a Siemens Scalance device, sent to the cloud, and easily retrieved for validation without disturbing end-customers.

Supporting release highlights

Supporting release highlights

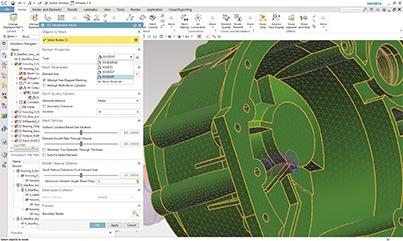

CAD-Centric Impact Testing

To reduce physical prototypes and testing time, Simcenter Testlab Neo now integrates CAD functionality into Impact testing workbooks. This integration improves measurement accuracy for calculating Blocked Forces and provides visual feedback to operators, reducing testing time and errors while enhancing precision.

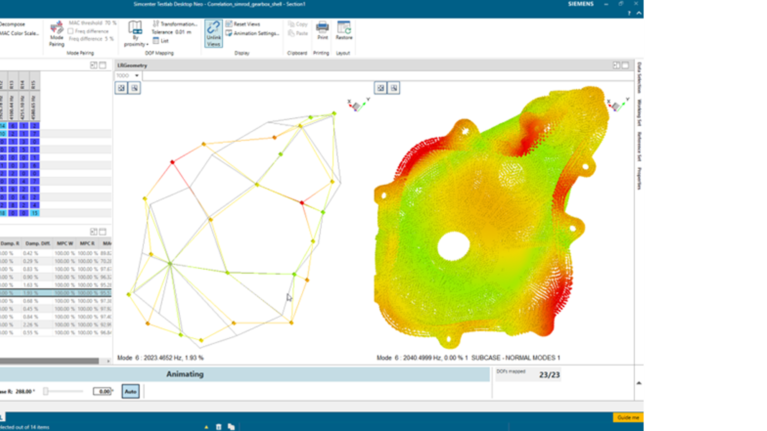

Modal Correlation

Manufacturers seek closer collaboration between Test and Simulation teams for shorter development cycles. Simcenter Testlab Modal Correlation workbook facilitates this by allowing Physical testing engineers to perform modal correlation, aligning mode sets from Test, Simulation, or both, even with differing geometries. The 3D driver offers seamless access to critical simulation formats.

Shock Control

The latest release extends Environmental Testing’s Shock control capabilities. It introduces MIMO Shock control for Multi-axial shaker testing and enhances SISO Shock control for large-stroke low-frequency hydraulic shakers.

Test subscription

Test subscription

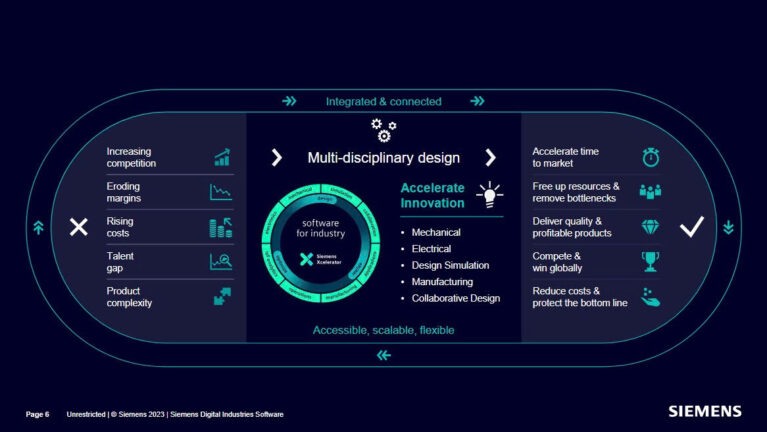

For both small and large companies, outfitting testing laboratories with data acquisition hardware and software can be a significant upfront investment.

Simcenter now offers Test Subscription, a flexible option granting access to Simcenter SCADAS hardware and Simcenter Testlab software on annual terms. This approach allows you to adapt physical testing to your budgetary constraints.

Source: Siemens

Contact us for free and detailed advice: