Cam solutions optimized for your needs

Easy to deploy and easy to learn

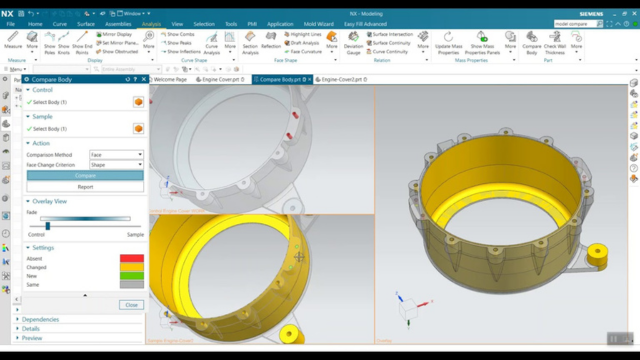

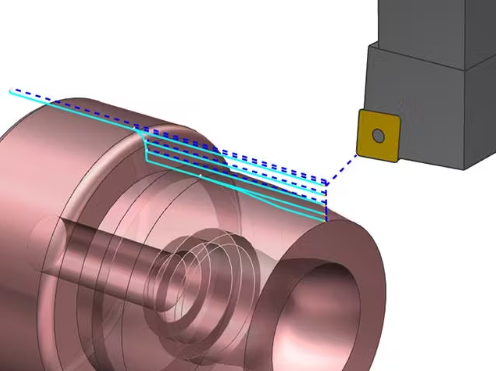

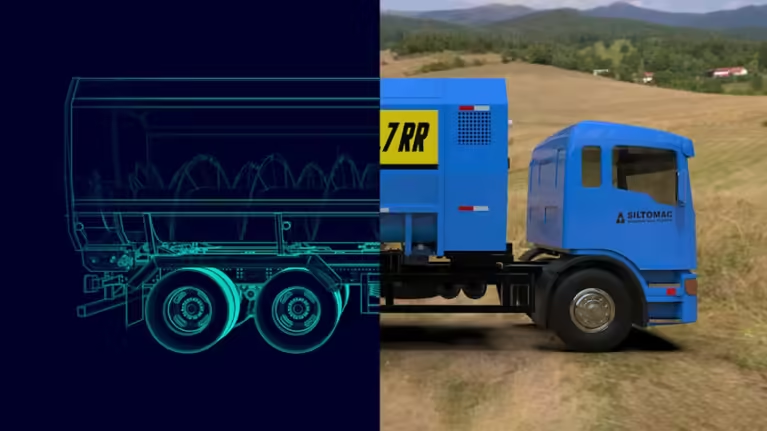

Solid Edge CAM Pro helps manufacturers define and execute a wide range of manufacturing processes, including milling, turning, and feature-based machining, with comprehensive machining simulation.

CAM Pro ensures accurate and efficient manufacturing processes working directly with Solid Edge parts and assemblies. Sending files from Solid Edge to CAM Pro is as easy as one click, and the data retains associativity so that late-stage design changes can be easily incorporated into the manufacturing plan.

Check out some of the additional benefits of Solid Edge CAM Pro

-

- Scalable solutions offer wide-ranging capabilities, including turning, milling, and feature

- based machining

- Maximize shop floor efficiency with a single unified CAM system-Postprocessing, including a searchable, online database of postprocessors ready for you to download and use

- Low cost of ownership, and easy to deploy, learn, and use

Minimum system requirements

-

- Windows 10 Enterprise or Professional (64-bit only) version 1809 or later

- 16 GB RAM-65K colors

- Screen resolution: 1920 x 1080

- 8.5 GB of disk space required for installation

For more information, please contact:

Vietbay CAD/CAM/CAE/PLM Team

Phone/Zalo/Whatsapp: 091 929 5520

Email: [email protected]

Website: www.vietbay.com.vn * www.cadcamcae.vn * www.vietbay.edu.vn