While ZWCAD has proven to be a powerful general-purpose CAD platform, MFG is an advanced CAD solution you can’t miss if you are from the manufacturing sector. Packed with a suite of mechanical toolsets, it is intended to help mechanical engineers create standardized designs easier and faster.

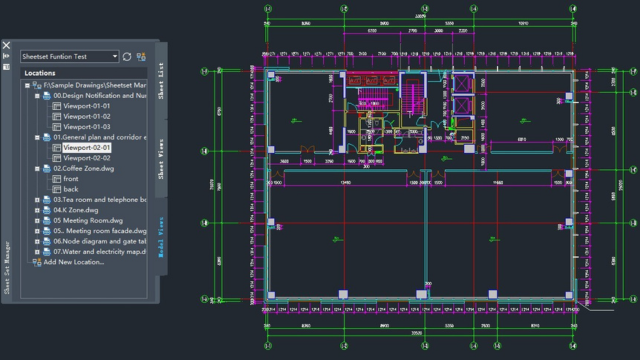

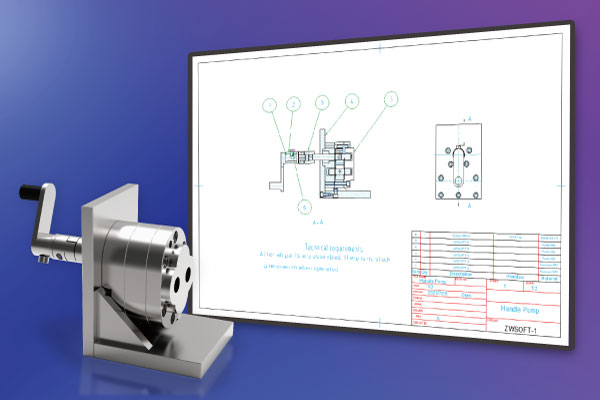

To demonstrate how MFG can take your design efficiency to the next level, we recently conducted a comprehensive comparison test between ZWCAD and MFG, using a hand pump as an example to perform common design tasks from drafting to detailing. The results revealed that it significantly boosted productivity by 51% compared to ZWCAD.

Let’s take a look at these tasks in detail to see how MFG achieved these efficiency gains.

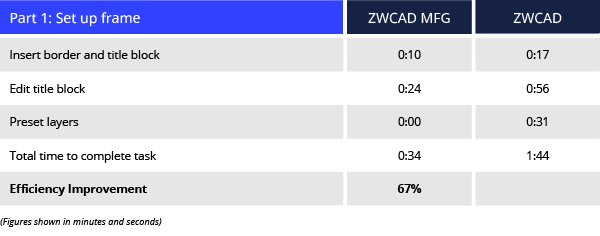

Part 1: Set Up Frame

Before starting any design, it’s essential to set up a drawing frame according to company standards. Here are the steps involved and time taken for this part:

The result showed that MFG boosted efficiency by 67% compared to ZWCAD in frame setup.

Setting up frames in ZWCAD requires manual tasks, which can be time-consuming and prone to errors. MFG supports over 10 national and international standards such as ISO, DIN, and ANSI, ensuring that your team can deliver standard-compliant documentation. It allows for easy setup of drawing borders and title blocks, with the ability to customize them to fit specific requirements. Additionally, it automatically generates layers for different objects and assigns them to corresponding layers, saving you time and effort.

Part 2: Modify Design

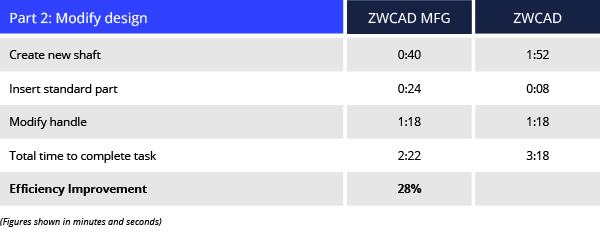

In the design phase, it’s common to change the design according to requirements. In this case, we modified the connecting shaft and the handle. Here are the steps involved and time taken for this part:

The result showed that MFG boosted efficiency by 28% compared to ZWCAD in design modification.

Drawing parts in ZWCAD is not a difficult task, but it requires many manual tasks. MFG offers an extensive library of standard parts, a powerful shaft generator, and more so you don’t have to draw everything from scratch.

Part 3: Create Part Drawing

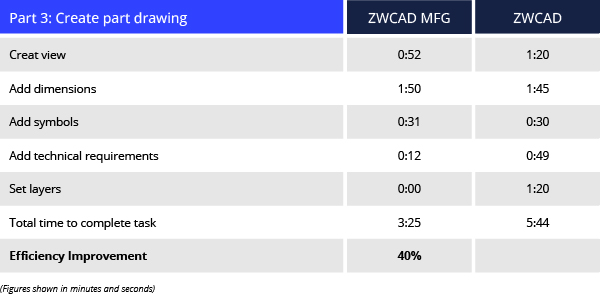

After finishing the modification of the design scheme, it’s essential to create a part drawing for production. Here are the steps involved and time taken for this part:

The result showed that MFG boosted efficiency by 40% compared to ZWCAD in part drawing drafting.

MFG offers a handy view creation tool, a blend of annotation functions and options, such as Power Dimension and Geometric Tolerance, and a library of technical requirements. All these features can help you create part drawings faster and more accurately.

Part 4: Create Assembly Drawing

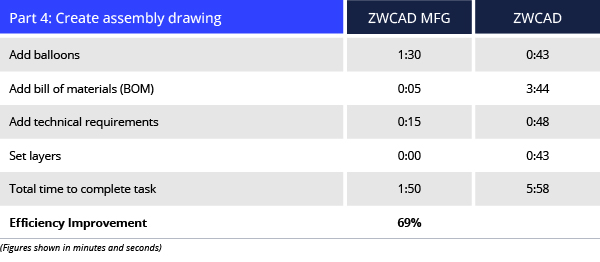

After creating the part drawing, it’s necessary to create an assembly drawing for material preparation and installation. Here are the steps involved and time taken for this part:

The result showed that MFG boosted efficiency by 69% compared to ZWCAD in assembly drawing drafting.

Adding balloons and BOMs in ZWCAD is labour-intensive, and errors might occur due to manual manipulation. MFG provides automatic BOMs associated with balloons and part properties, greatly improving efficiency and reducing errors.

Conclusion

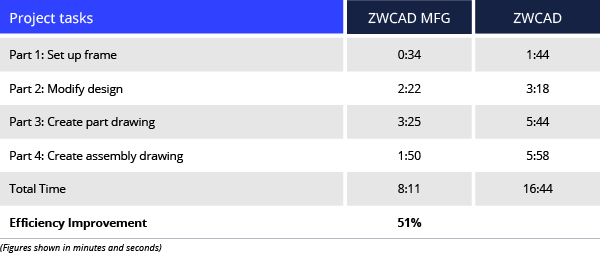

Here’s a complete look at the time taken for the complete project:

According to the study, MFG can boost efficiency by 51% compared to ZWCAD in performing common design tasks. It offers standardized, intelligent, and customizable functions. This not only helps mechanical engineers improve design and accuracy, but also enables companies to enhance team collaboration, save costs, bring better products to market faster, and stay ahead in their industry.

(Source: ZWSOFT)

Read more:

- ZWCAD 2025: Game-Changing Features in 2D and 3D CAD

- Introducing ZWCAD MFG 2025: Advanced 2D CAD for Manufacturing

- Discover the Power of a More Flexible Workspace in ZWCAD 2025

Contact us for free and detailed advice: