“PLM runs on the cloud. ERP also runs on the cloud. MES is gradually moving to the cloud. So what about CAM?”

Now, CAM is joining that trend. In today’s fast-paced manufacturing environment, on-premises CAM solutions slow down collaboration, limit scalability, and prevent teams from accessing, sharing, and processing production data in real time.

Manufacturers are constantly seeking new ways to streamline operations, increase efficiency, and stay ahead of the competition — and moving to cloud-based CAM systems is the next logical step.

Cloud CAM systems are changing the game entirely — providing secure access, real-time process planning, and the flexibility modern manufacturing demands.

In this article, we’ll explore why moving your CAM software to the cloud makes sense, how to transition effectively, and how Siemens can support you throughout the process.

1. The Rise of Cloud-Based CAM Solutions

In recent years, the manufacturing industry has undergone a major digital transformation, with cloud computing at its core. Cloud-based CAM software — also known as CAM-as-a-Service (SaaS) — is gaining popularity as manufacturers recognize its advantages over traditional on-premises CAM tools.

Cloud CAM solutions allow users to access their software and data anytime, anywhere, from any internet-connected device. This eliminates the need for local installations and hardware, reduces IT workloads, and enables distributed teams to collaborate effectively.

Additionally, cloud CAM solutions often feature automatic software updates and seamless integration with other cloud tools, ensuring manufacturers always have access to the latest features and capabilities. This helps maintain a competitive edge and enables faster adaptation to market changes.

2. Benefits of Moving CAM Software to the Cloud

- Improved accessibility and collaboration: Cloud-based CAM software allows users to access design, simulation, and production data anytime, anywhere, on any device. This supports remote collaboration and enables teams to work on the same project from different locations. By removing distance barriers, cloud CAM solutions boost productivity, speed up decision-making, and enhance communication among stakeholders.

- Flexibility and scalability: Cloud CAM platforms are inherently scalable, allowing manufacturers to easily add or remove users, storage, and computing power as business needs change. This flexibility helps companies quickly adapt to market fluctuations, seasonal shifts, or sudden demand spikes without heavy investment in hardware or software installations.

- Reduced IT burden and total cost of ownership: With cloud-based CAM, software updates, security patches, and infrastructure maintenance are handled by the cloud provider. This significantly reduces the internal IT workload, allowing teams to focus on strategic initiatives. The subscription-based pricing model also provides lower upfront costs and predictable operating expenses.

- Enhanced data security and disaster recovery: Cloud providers invest heavily in advanced security measures, including encryption, access control, and backups, to protect sensitive manufacturing data. In case of hardware failure, natural disasters, or unexpected incidents, cloud CAM offers superior data recovery, minimizing downtime and data loss.

- Automatic updates: Cloud CAM solutions deliver the latest features, performance enhancements, and security improvements automatically — no manual installation required. This minimizes downtime and ensures users always operate on the most advanced version.

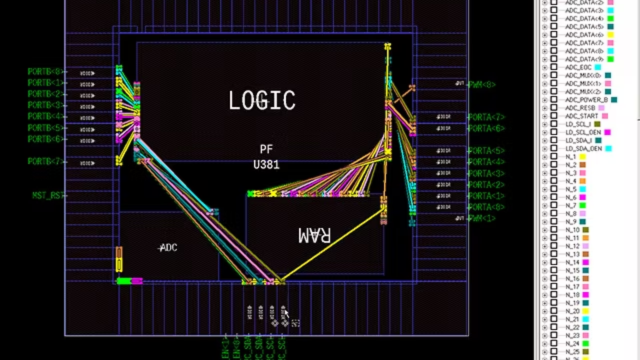

- Access to advanced technologies: Cloud solutions often integrate AI, machine learning, and advanced simulation tools. By leveraging these modern capabilities, manufacturers can optimize workflows, improve product quality, and enhance competitiveness.

3. How to Transition to Cloud-Based CAM

Transitioning CAM software to the cloud can be transformative but requires careful planning and execution. Key steps include:

- Assess your current CAM system: Begin by evaluating your existing CAM software, hardware, and infrastructure. Identify the features, integrations, and performance requirements essential to your operations. This helps determine the best-fit cloud CAM solution for your needs.

- Evaluate cloud CAM options: Research and compare available cloud CAM solutions, such as Siemens NX X Manufacturing. Consider scalability, security, usability, and integration capabilities to ensure the chosen platform meets your organization’s needs.

- Plan the migration: Develop a detailed migration plan outlining steps, timelines, and resources needed. Include data transfer, user training, and system integration with existing tools.

- Ensure a smooth transition: Collaborate closely with your cloud provider to ensure a seamless migration. Support user adoption by offering training and technical assistance, and establish clear communication channels for troubleshooting.

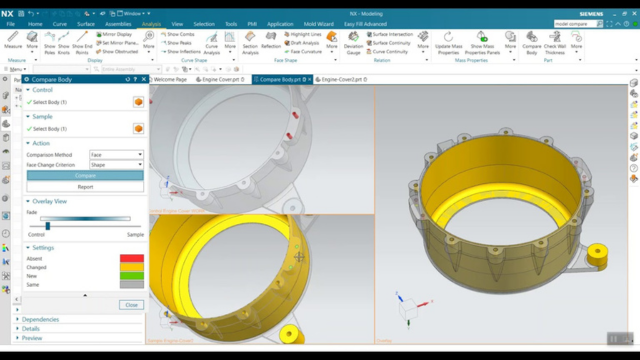

- Leverage Siemens expertise: As a global leader in CAM software and cloud manufacturing solutions, Siemens can be your trusted partner in digital transformation. Siemens’ NX X Manufacturing platform provides a powerful, cloud-based CAM solution integrated with Teamcenter Share, forming a complete cloud manufacturing ecosystem.

Siemens experts can guide you through every step — from assessing your current CAM system to implementation and optimization — while offering training and support to help your teams maximize the platform’s potential.

4. Manufacture, Collaborate, and Scale with NX X Manufacturing

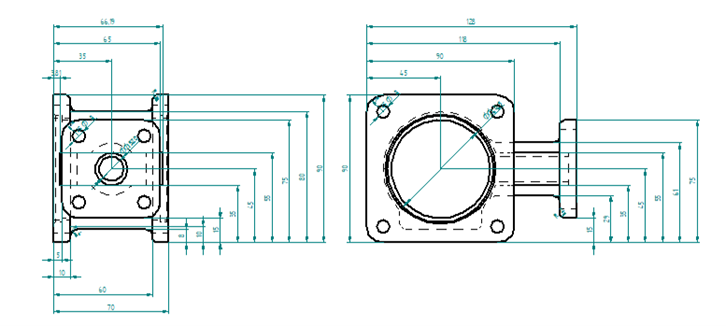

Modern cloud-based CAM solutions like NX X Manufacturing bring the full power of NX for Manufacturing to the cloud — integrating CAD, CAM, probing, and collaboration tools in one platform.

With NX X Manufacturing, manufacturers can:

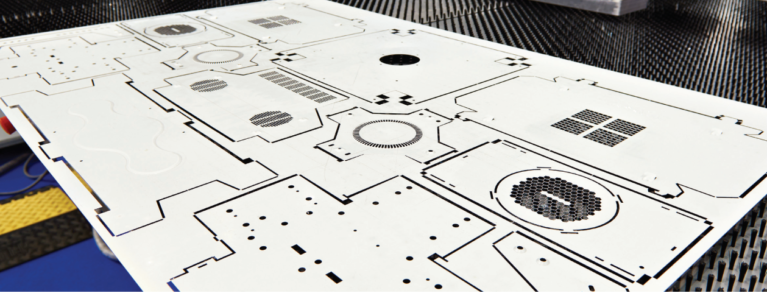

- Increase productivity: Generate toolpaths and machining strategies using scalable cloud computing for complex parts, and simulate CNC programs virtually to reduce errors, scrap, and rework.

- Optimize processes: Shorten production cycles and streamline operations with advanced planning and process validation tools.

- Collaborate securely: Work seamlessly across teams and locations while maintaining data integrity and version control.

- Flexible access: Use the software via desktop installation or stream directly from the cloud using the Remote Add-on, supporting hybrid workflows. Cloud deployment also simplifies IT management and licensing while reducing costs.

- Centralized license management: Simplify administration and lower operational costs.

- Cost efficiency: The SaaS model lowers total costs by eliminating hardware investment and reducing IT maintenance. Value-based licensing enables flexible spending per project, ensuring cost-effective resource use.

- Automatic updates: Keep all teams up to date with the latest features and enhancements.

- Value-based licensing: Scale features as needed and access key functionalities through add-on packages.

Built on the same foundation as NX for Manufacturing, NX X Manufacturing connects design and production, enhances collaboration, and delivers a secure, flexible, and scalable cloud-based manufacturing solution — enabling businesses to move confidently from design to production with minimal risk.

5. The Future of Manufacturing Is in the Cloud

As the manufacturing industry continues to evolve, cloud-based software is becoming an inevitable trend. Features like virtual machining validation and knowledge-based machining enable continuous process optimization and adaptability to new challenges.

The integration of PLM and CAD systems — along with error-free simulation and production-ready data generation — makes cloud-based CAM solutions essential for modern manufacturing operations.

By harnessing the power of cloud computing, manufacturers can achieve:

- Better accessibility and collaboration

- Greater flexibility and scalability

- Reduced IT burden and predictable costs

- Access to cutting-edge technologies for smarter, faster production

By moving your software to the cloud, your business positions itself for long-term success — staying ahead of the competition and leveraging the latest advancements in manufacturing technology. The future of manufacturing is collaborative, scalable, innovative, and sustainable.

Read more:

- Post Processor Service for NX CAM

- Professional Reverse Engineering Service – An Optimal Solution For Product Development

Contact us for free and detailed advice: