Automotive stamping dies and press lines are high-cost, long lead-time investments. To maximize return on investment (ROI), it’s important to streamline development and commissioning of new lines, while flexibly adapting existing lines to new designs. Your fully functioning press line’s ROI depends on the time required for die engineering, optimization, building and setup as well as press line commissioning and production ramp-up. ROI also depends on the press line’s throughput while running in production. In addition, because of the complex nature of today’s press lines, the success of your stamping process is never fully deter-mined until the commissioning process is complete.

As you plan, design, validate, manufacture and commission your press line equipment, you can leverage Siemens Digital Industries Software’s complete suite of CAD, CAM, CAE and PLM solutions and Siemens production equipment (which includes controllers and drivers) to:

- Reduce the time needed for production ramp-up

- Achieve greater throughput without sacrificing quality

- Meet material waste reduction objectives

Introducing Siemens automotive stamping solutions

Siemens automotive stamping solutions are used by leading companies to optimize operational efficiency and reduce time, cost and errors in design, planning and production of sheet metal parts and dies.

Best-in-class software applications and production equipment

Siemens provides a comprehensive and integrated foundation of CAD/CAM/CAE/ PLM applications for planning, designing, simulating and manufacturing complete stamping die press lines. Siemens SIMOTION controller and drives deliver stamping line equipment that facilitates production reliability, intelligent energy management and maintenance cost reduction.

Complete and integrated solution set from planning to commissioning

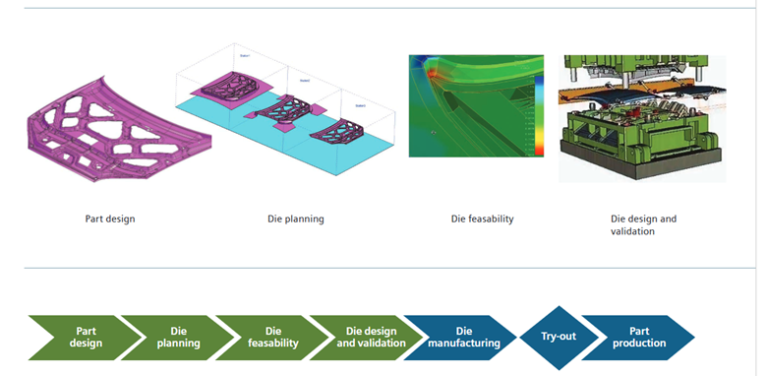

The stamping process plays a major role in determining the efficiency of auto-motive body part production. Ever-increasing requirements for shorter production times are met by leveraging Siemens’ specialized planning, design, manufacturing and simulation solutions.

Process planning and data management

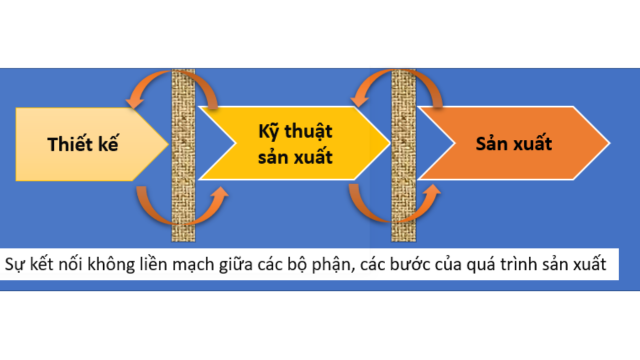

Stamping process development is a highly collaborative activity requiring effective communication across multiple disciplines including product design, tooling design, manufacturing engineering, industrial operations and production teams. Siemens solutions provide process planning, data management and configuration control, as well as flexible reporting, to ensure the availability of the right data, when and where it’s needed.

Business value

Whether you need to improve a specific phase of die set development or optimize the entire integrated process chain, Siemens automotive stamping solutions are scalable and can be implemented to your specific requirements. Siemens automotive stamping solutions are designed to generate immediate value for turnkey operations and press line manufacturers while providing press line suppliers with a higher degree of confidence in a proposed press system. In addition, these solutions deliver advantages to automotive OEMs, including higher return on capital investment, faster time-to-market and improved plant productivity.

Increase speed to production: You can shorten overall die engineering and press line commissioning time by utilizing Siemens’ integrated applications for die design automation, documentation, analysis, simulation, NC programming and press line programming capabilities.

Maximize throughput: You can engineer the optimized combination of transfer motion and stroke rate. Siemens stamping die solutions interface the digital model of the working press with the actual press controller software to generate realistic motion curve data, calculate holding forces for cups and grippers and eliminate potential bottlenecks while optimizing overall throughput

PROVEN VALUE

- Die design time reduced by 20 percent

- Die modification time reduced by 40 to 45 percent

- Reduction in modification costs

According to MUSCO Stamping, a division of Mahindra Ugine Steel Co.LTD

Consistently achieve quality: You can optimize and validate the full working design of press line equipment long before it is built and installed. Siemens automotive stamping solutions enable engineers to eliminate design errors and maintain a quality product by providing a full working digital model of the press, its associated tooling equipment and behavior

Boost productivity and reduce cost: You can achieve significant gains in manufacturing productivity and cost reduction by reusing industry best practices to reduce errors and rework. Siemens automotive stamping solutions are built with proven automotive stamping know-how and packaged into a set of process-based applications streamlined to address the most complicated die development projects.

Manage complexity: You can manage the data and processes associated with the stamping die design through commissioning process chain. Siemens automotive stamping solutions enable you to leverage product change, updates and dependencies throughout the development process, resulting in improved quality and a shortened time to production

PROVEN VALUE

- Design time reduced by 50 percent

- Lower die costs

- Reduced rework

- NC programming time cut by 50 percent

- Machining 30 percent faster

According to Rasandik Engineering Industries India LTD

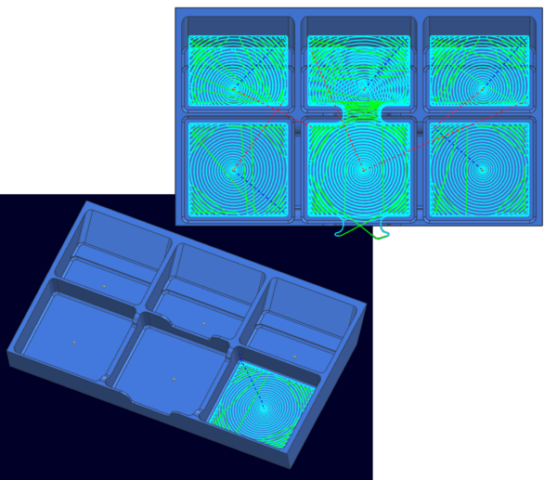

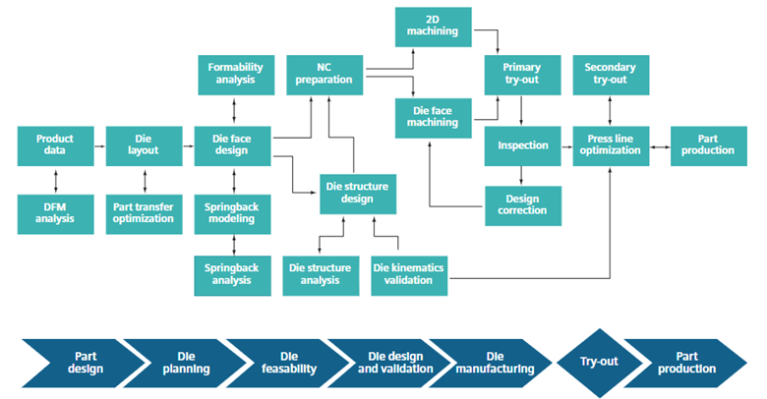

Siemens total die design solution diagram

Siemens total die design solution diagram

Read more:

- Increase loading capacity of scissor-lift by 50 percent with Simcenter

- Part Manufacturing Data Management With Tomorrow’s CAM

- Integrated Data Management With NX X

Contact us for free and detailed advice: