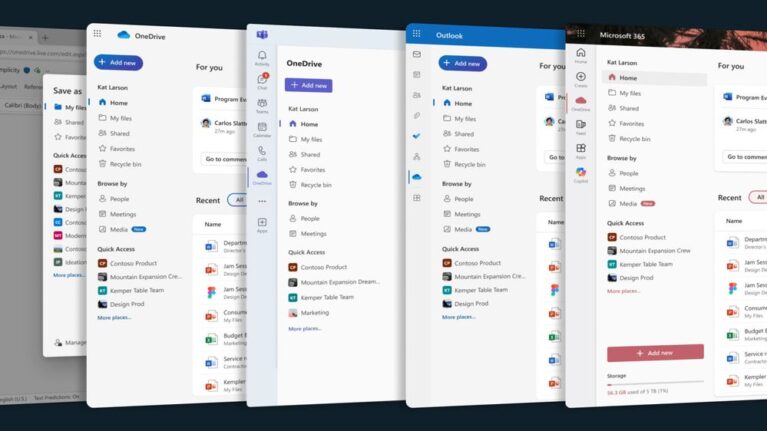

Microsoft Cloud for Manufacturing brings the best of Microsoft and our partners together to jointly accelerate the digital transformation in manufacturing, unlocking engineering and design innovation with cloud computing and AI, building a more resilient supply chain to anticipate risks, enabling intelligent factories, and helping modernize the customer experience with the latest digital technologies.

Manufacturers rely on an ecosystem of many different industry solutions from different vendors. Microsoft Cloud for Manufacturing orchestrates this complex ecosystem of solutions, delivering transparent, efficient, and interoperable processes, to democratize data insights, and foster collaboration across the value chain.

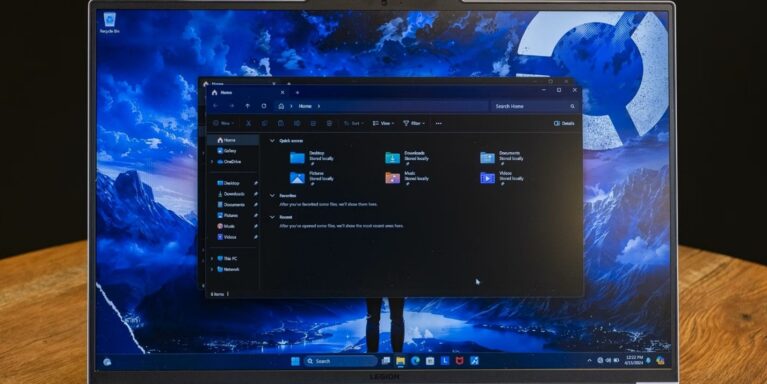

Enable intelligent factories

Enable the intelligent factory of the future by using the Internet of Things (IoT), data analytics, AI, and cloud connectivity to extract critical data from across operational technology (OT) and information technology (IT) to drive improvements in overall equipment efficiency, operations visibility, and sustainability. Implement AI-driven cost optimization use cases like predictive maintenance or autonomous machine optimization at scale. Improve the quality of your products by rolling out computer vision models to detect defects, analyzing machine data for root cause analysis, and sharing real-time production insights back to design and engineering. Connect your frontline workers with communication and collaboration tools to onboard and upskill them faster.

Resilient manufacturing supply chain

Build a resilient and sustainable manufacturing supply chain by holistically analyzing your organization’s production and operations data, your multi tier supplier data, and market signals with the advanced analytics and AI capabilities embedded into the Microsoft Dynamics 365 Supply Chain Management platform. Gain real-time visibility into the supply chain to better predict and manage potential risks. Optimize planning processes end-to-end, use data and AI to improve demand forecasting models, and optimize inventory levels. Increase customer service and satisfaction levels with warehouse automation and intelligent fulfillment systems, all of these while tracking and reducing the carbon footprint.

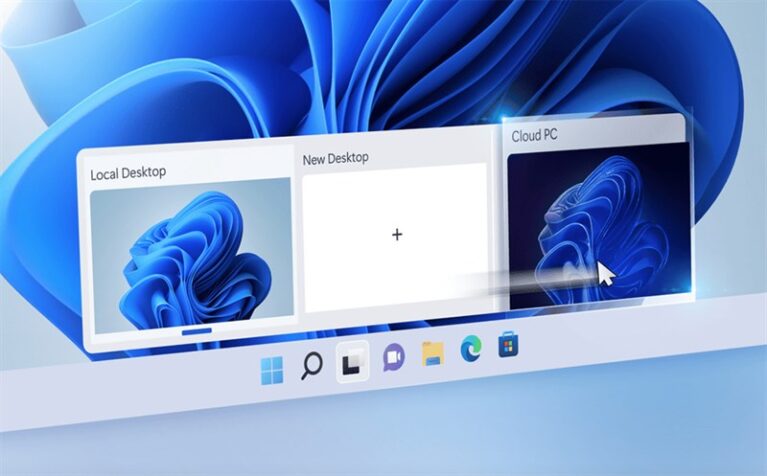

Unlock innovation and introduce new products

Unlock innovation and introduce new products more efficiently reducing costs without sacrificing quality and function. Evolve your technology roadmap to adopt industrial metaverse capabilities like AI, mixed reality, digital twins, and edge-to-cloud, creating a digital loop of your assets and operations. Streamline product development through cloud-based computer-aided design and product lifecycle management applications, use high performance computing to power simulations for digital verification and validation, and roll out generative AI to augment your design and engineering processes. Use software-defined products to create digital feedback loops, gather usage insights, and open new business models with a digital services ecosystem.

Modernize manufacturing customer experience

Modernize the overall customer experience by helping your organization’s marketers, sellers, and service agents better understand customer needs and create delightful digital experiences with data analytics, conversational AI, remote collaboration, and mixed reality. Empower sales teams to close new and recurring revenue with speed and predictability with a flexible and comprehensive cloud-based customer relationship management (CRM) platform. Attract new customers, qualify high-value prospects, and build knowledge of your most impactful personas by gaining a 360-degree view of your customers. Turn your service operations into a profit center and expand the reliability of your product lines with cutting-edge mixed reality and remote collaboration capabilities.

Source: Microsoft

For more information, please contact: