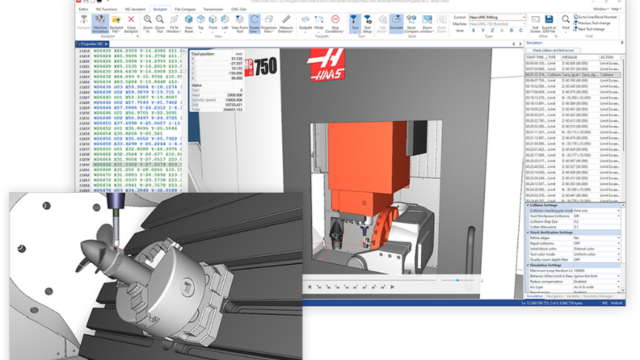

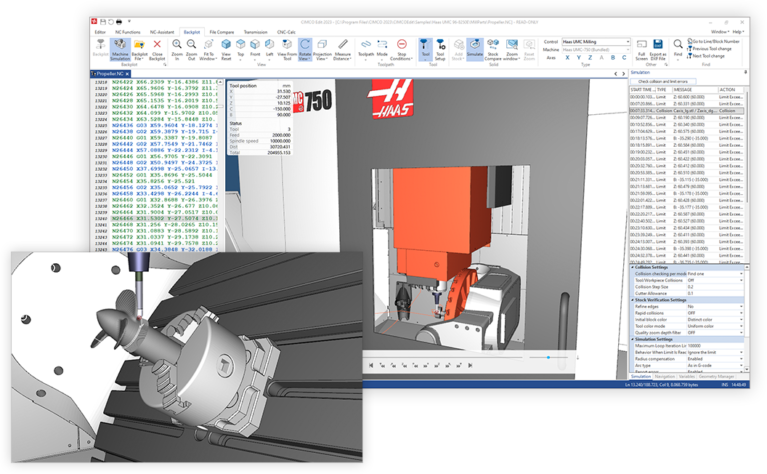

When it comes to Cimco software, most CNC machining technicians are familiar with Cimco Edit. This is a popular software that allows CNC machining technicians to edit NC code, simulate tool paths, and evaluate the safety of CNC machining programs.

However, Cimco’s CNC machining solution does not stop at software that supports editing and simulating NC code machining programs, but Cimco offers a comprehensive solution for CNC machining, including support for pre- and post-processing stages of CNC machining in real time. Let’s explore some features you may not know about:

Cimco’s Comprehensive CNC Machining Solution

Cimco MDM (Machining Data Management)

- CNC program management and permission control: The software efficiently manages CNC data, allowing access permissions based on each individual’s role.

- Team collaboration support: This feature enhances coordination between CAM programming engineers, CNC machine operators, and other related departments.

- Traceability: Easily track the history and machining process of each product, supporting quality management and error analysis when needed.

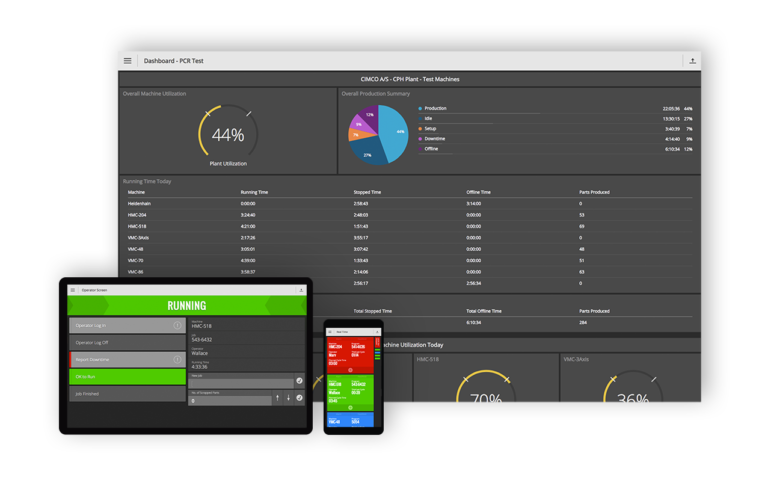

Cimco MDC (Machining Data Collection)

- Connect to CNC machines and collect real-time production data: This feature allows managers to monitor the operational status of machines, including states such as running, stopped due to errors, or halted for tool and workpiece setup.

- Generate summary reports: Cimco MDC enables the creation of reports on the operational status of all machines in the workshop, helping to optimize production processes and improve efficiency.

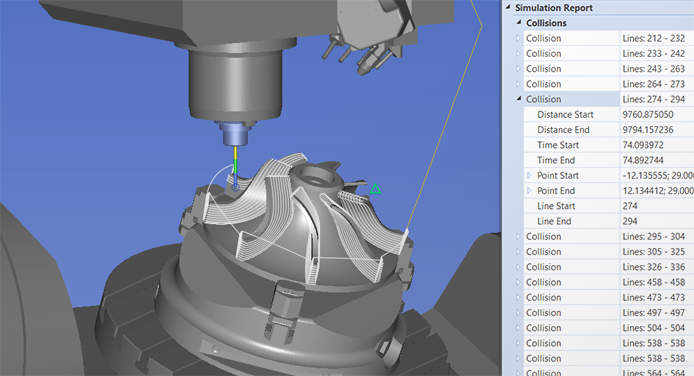

Cimco Machine Simulation Module

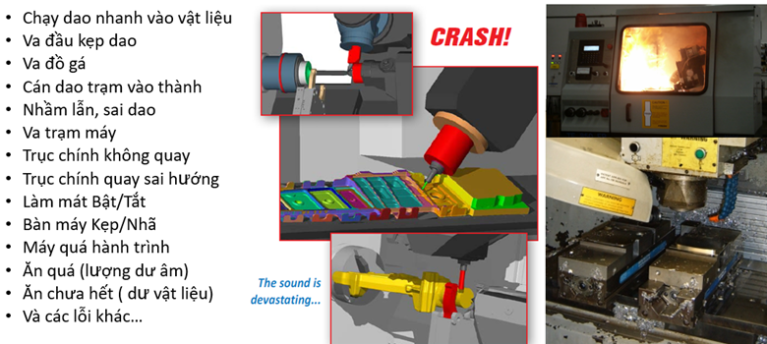

- Configure and simulate machining with 3D models of CNC machines, fixtures, tools, and workpieces: This feature is particularly useful in complex machining environments, such as multi-axis machining or mill-turn combined machining.

- Validate machining programs before actual implementation, minimizing risks related to collisions during machining.

Technical Requirements for Implementing Cimco’s Connection Modules

To deploy and use Cimco’s connection modules between Cimco software and CNC machines, several connection requirements are needed:

- CNC machines must have RS232 ports or Internet connectivity.

- Depending on the customer’s existing system, additional Moxa adapters and a database server system may be required.

- The implementation of connections requires the provider to have sufficient technical expertise and knowledge of CNC machines to ensure accurate connection setup and configuration.

Vietbay is proud to be the official distributor of Cimco in Vietnam, providing comprehensive support from solution consulting, implementation, to software training. With an experienced technical team in the field of CNC machining, we are committed to delivering the best service and complete solutions to optimize production processes for our customers.

Read more:

Contact us for free and detailed advice: