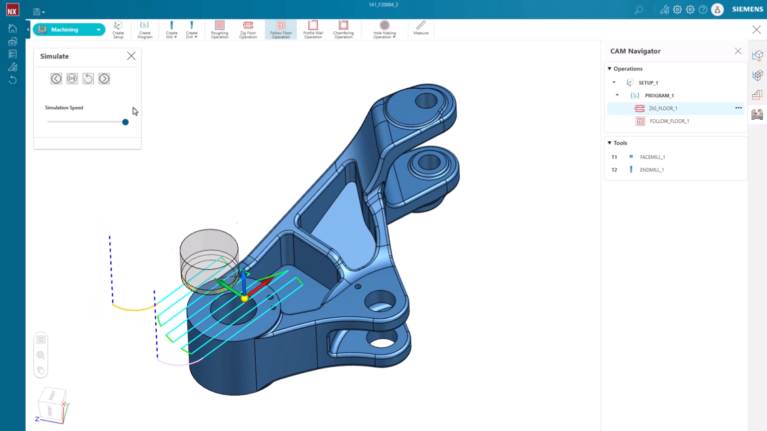

NX CAD/CAM leverage the flexible turning solution to quickly program simpler jobs as well as the most challenging multi-spindle, multi-turret applications. Program A-axis and B-axis turning operations.

Program advanced turning operations

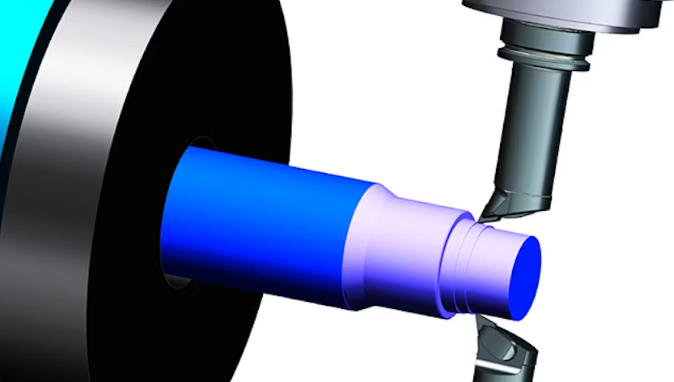

Use either 2D part profiles or full solid models to program roughing, multiple pass finishing, grooving, thread cutting and centerline drilling operations. Innovative turning methods, such as PrimeTurning, can accelerate machining and improve productivity by up to 50%.

Automatically track turning volumes with the In-Process Workpiece (IPW) technology, enabling 3D visualization and efficient handling of design changes.

Design with integrated CAD

Model parts, blanks, fixtures and complete machine setups using integrated CAD for modeling and assembly. Prepare part models for NC programming using synchronous technology.

Output validated programs

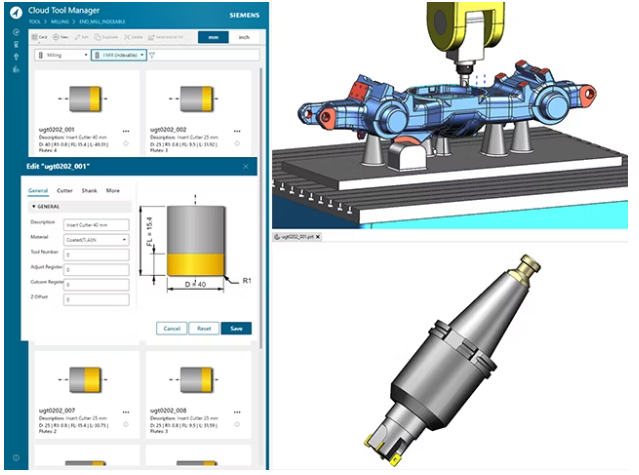

Generate validated, production-ready NC programs, using the cloud-based postprocessing solution and integrated machining simulation. Digitally connect planning and production with associative shop documentation, including tool lists and setup sheets.

Featured capabilities

Pinch turning

Pinch turning, an advanced cutting method, enables simultaneous machining by two opposing cutting tools.

It balances the cutting forces of two opposing cutting tools and minimizes parts deflection, allowing deeper cuts and faster machining. Additionally, one of the tools can perform a semi-finishing operation while the other, slightly trailing the opposing tool, performs the finishing operation.

Pinch turning operation in NX CAM provides two modes for higher throughput:

- Balanced: the opposing tools are aligned and cut the same diameter

- Merged: one of the tools trails the opposing tool and the tools cut different diameters

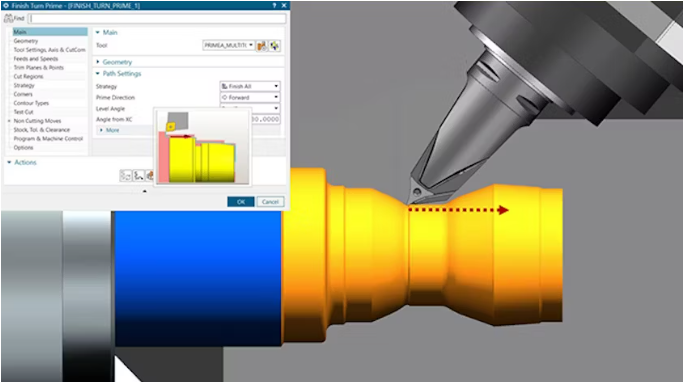

PrimeTurning

PrimeTurning™ is an innovative machining method, implemented in cooperation with Sandvik Coromant. High-performance CoroTurn Prime inserts are used for this high-performance machining operation.

The tool enters the workpiece at the chuck and removes material as it moves toward the end of the component, away from the chuck. This enables use of a small entering angle and more aggressive cutting parameters. Additionally, you can use the CoroTurn Prime inserts for conventional turning – from part-end toward the chuck.

PrimeTurning can be used for a dual roughing operation and continuous B-axis too.

For certain applications, PrimeTurning offers increased productivity by more than 50% compared to conventional techniques, while extending tool life by two times.

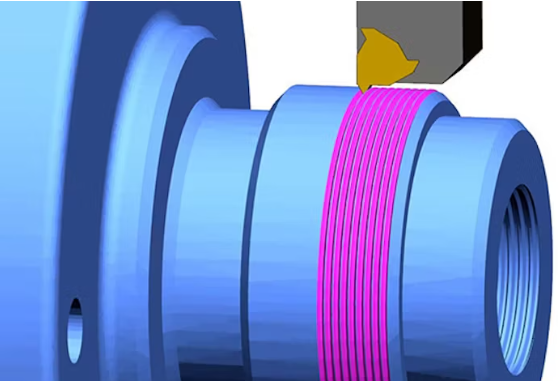

Automated threading

The thread turning automates the programming of this machining cycle, which can be time consuming and prone to errors if traditional methods are used.

NX automatically retrieves the relevant information (for example: pitch, start and end of thread) from the 3D part model, and it creates the threading toolpath. Program straight and tapered threads.

Multiple infeed methods are available, including radial, front and rear infeed. The infeed method defines how the insert is applied to the workpiece to create the desired thread form.

The IPW capability enables realistic 3D material removal simulation for quick and accurate validation.

This automated programming method for threading operations helps you minimize manual input, eliminating errors and accelerating programming.

Source: Siemens

Vietbay – with more than 20 years of professional experience in the field of consulting and technology transfer of IT platform software and industrial software technology solutions supporting digital design optimization (CAD) processes, Machining programming (CAM), simulation analysis evaluation (CAE), data management (PDM), machining management (CNC) and product lifecycle management (PLM) solutions for customers operating Active in industries: electronic components, cars and motorbikes, molds, consumer goods, industrial machines… We commit that with extensive experience and dedication, Vietbay will bring good solutions most advanced for customers in this era of rapid digital transformation.

Learn more:

Contact us for free and detailed advice