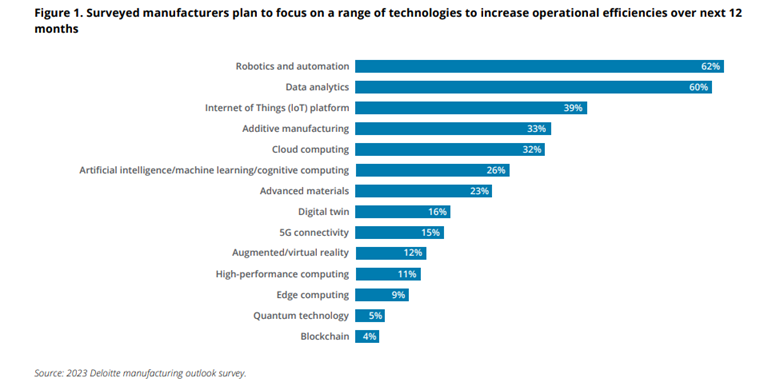

This large percentage indicates that the manufacturing industry recognizes there is still work to be done before being able to fully reap the benefits of the Industry 4.0 technologies. This also validates that cloud-based digital manufacturing solutions, like Process Simulate Collaborate, will help accelerate manufacturers’ plans to implement their Industry 3.0 journeys quickly and cost-effectively.

Architected for the cloud, Process Simulate Collaborate is a SaaS solution that enables users to work from any device, at home, in the office or on the shop floor. Cloud-based solutions like this provide a new level of flexibility and scalability that aligns well with the forecasted trends for robotics and automation.

Robotics processes and automation are top of mind for Siemens, especially with digital manufacturing solutions like Process Simulate, which helps companies facilitate simulation, validation, optimization and commissioning of complex manufacturing processes. From concept, engineering, and commissioning to production and continuous improvement, Process Simulate empowers manufacturers’ operations with process verification in a virtual 3D environment.

The innovation doesn’t stop there. Just as manufacturers continue to invest in advanced technologies, we continue to invent the right mix of technology to strengthen and complement the core of our digital manufacturing portfolio. For example, Process Simulate users can now experience an unprecedented level of collaboration with the most recent launch of Process Simulate Collaborate, Siemens’s latest SaaS offering. Experience the free trial today and discover how the 3D cloud-based simulation application now enables easy sharing, communication, and collaboration on Process Simulate studies. Because it is architected for the cloud, this solution simplifies the deployment and enables users to securely connect everyone, wherever they work. Stakeholders require only internet access to participate and new users can be invited quickly and easily.

Built for Process Simulate engineers, line builders, OEMs, and system integrators, Process Simulate Collaborate helps to improve productivity and communication among internal and external teams so users can dynamically visualize, review and analyze factory production lines and workcells authored in Process Simulate without the need for a software installation, making simulation studies easily accessible from anywhere, at any time.

Vietbay CAD/CAM/CAE/PLM Team

Phone/Viber/Zalo/Whatsapp: 091 929 5520

Email: [email protected]

Website: www.vietbay.com.vn * www.cadcamcae.vn * www.vietbay.edu.vn