By digitally expanding your machine shop, you can become more competitive, efficient and profitable. A digital machine shop provides powerful advantages , including:

Reduce turnaround time by connecting people, equipment and the entire process with a digitalized process.

Deliver high-quality parts on time by predicting and eliminating errors using a digital twin of your part, resources and the entire process, and

Expand and grow your business by implementing new automation technologies, such as On-Machine Probing

In this presentation we will discuss how NX CAM On-Machine Probing (OMP), a target-oriented solution for NC programming, with the extensions for post-processing and simulation, can help you benefits a digital machine shop.

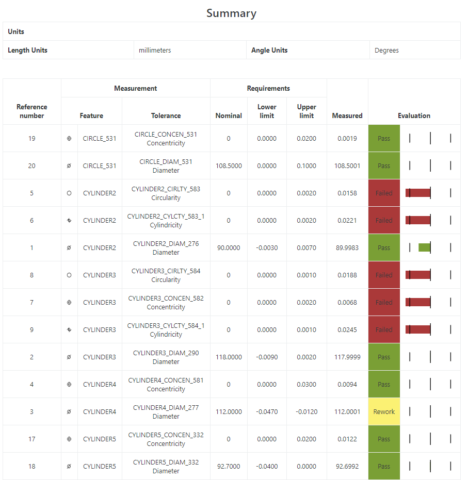

The NX Metrology solution provides tools to automate CMM measurement programming for any CNC machine or measuring machine, including key functions:

- Offline Inspection Programming

- Online Inspection Execution

- Hardware agnostic environment

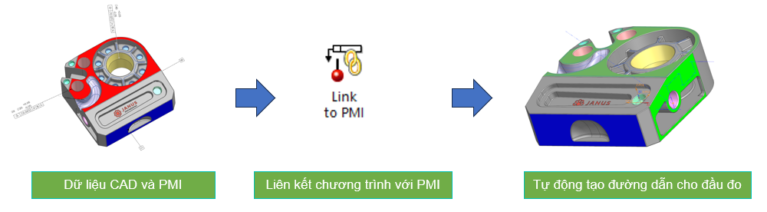

- Automatic program generation by PMI or MBD

- Capture company best practices with configurable machine templates & rules

- NX and Teamcenter, complete PLM integration

- Automatic collision avoidance

- Automatic program update to geometry change

- Up to 80% programming time reduction with automation of program generation via PMI or MBD

- Based on Industry standard DMIS 5.2

NX Metrology solution has increased compatibility with most measuring machine brands such as MCOSMOS, Mitutoyo, Renishaw, Hexagon, Zeiss, CMMEdiator…

Allows connecting, operating and monitoring the product quality assessment process through the open UI port, can export reports into HTML, PDF, CSV, DML formats.

Source: Siemens

Contact us for free and detailed advice