The Development of CNC Factory

The highly automated motion control systems always include three main components as same as pervious systems. They require a command controller (whether a digital or analog system or a handle) to activate, a driving system such as an engine or cylinder or valve or clutch; and a response system such as an encoder.

The role of traditional mechanical engineers is fading in the 21st century because technology is developing rapidly. In order to meet higher need of specialist in CNC machining, many companies or orgianizations such as Institute of Commercial Engineering recommend to have more training programs of technology knowledge and digital skills for the mechanical engineers. As recorginized issue, jobs regarding to CNC technology shall increase upto 40% of total offered jobs in various industries in near future.

As the global trend, CNC technology is upgrading to new generation with higher automation, precision and productivity. Futher more, manufacturers now are interested in applying new connected, integrated and synchronous solution which helps manage and maintain CNC machines, monitor CNC process at real time. New technology such as IoT allows machines can talk to each other through LAN, wifi, Rs232 etc or by an industrial software. Application of digital technology will assist manufacturers to optimize machining efficiency, reduce time and risk, cost-effective, and especially reduce depending on operating resources. Nowadays, digitalization for CNC machining is the critical trend of the manufacturers.

What is Digitalization of CNC Machining Process?

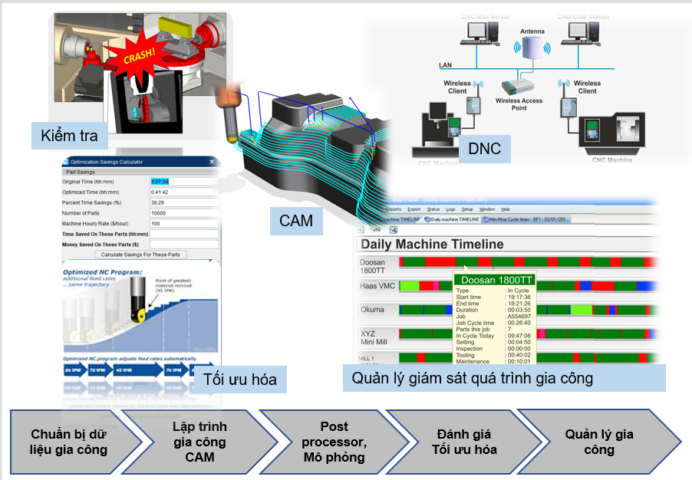

The CNC machining process digitalization is the process of application of technology on machining processes to automate, synch and convert data digitally. The CNC digitalization can perform in the whole of machining process that includes programming, managing data, export and manage work order data (Shop document – CAM sheet), send the data directly to CNC machines, collect digital data and monitor the CNC machining processes as well as create reports of errors and performance. All data will be connected and managed on the local server or cloud platform. The CNC machining process digitalization allows users easily access the system to manage and monitor data but also simulate CNC machines.

Picture 1: Digitalizing Process of CNC Machining

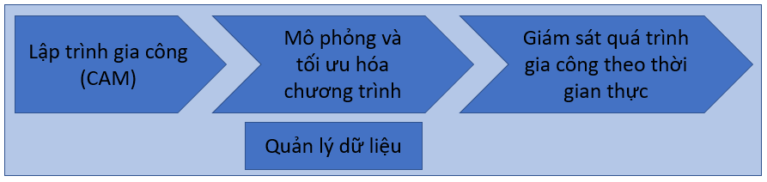

Digitization for total CNC machining process

Picture 2: Stages of Digitalization of CNC Machining

Picture 2: Stages of Digitalization of CNC Machining

Automately CNC Programing: This solution using CAM software which support programming based on 2D and 3D drawing of the product, then post NC toolpath to NC code and create a Shop document (CAM sheets). The NC code data is transferred to the next stage by software that popular using such as Siemens NX CAM, MasterCAM, Cimatron, PTC, or WorkNC.

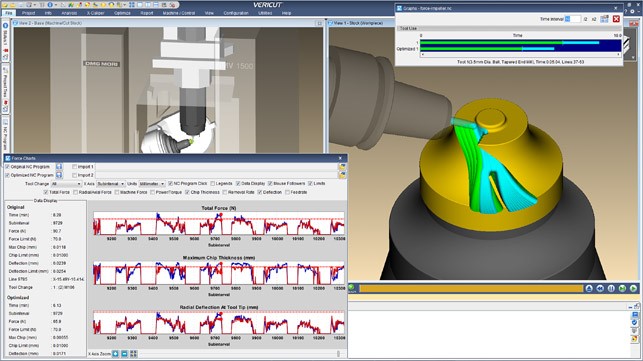

Simulation and Optimization of CNC Machining: After the NC program is posted from the CAM software, we need to evaluate and verify the program to avoid collisions as well as maximize the machining program. The evaluated and optimized NC program will be sent directly to CNC machines through different protocols such as RS232 or LAN or wifi which depending on technology capability of the CNC machine. VERICUT is considered as the most optimized solution of CNC machining.

Picture 3: Digital Twin of CNC Machine in Verficut software

Picture 3: Digital Twin of CNC Machine in Verficut software

Real-time Monitoring of CNC Machine: After being transferred to the CNC machine to run machining program, the entire of actual machining processes of CNC machines can be monitored and reported at real time by software to evaluate schedule and productivity, tools or machine status. Management levels can remotely access and supervise by computer or smart display devices. The popular software for this activtity is CIMCO MDC.

Picture 4: Real time Management of CNC Machining

Picture 4: Real time Management of CNC Machining

Data management and machining processes: The manufacturers can use software to manage all machining processes and its data effectively. All data of programming data, documentation, approval processes, plans and schedules can be monitored without using paper documents. This data management solution integrates and connects all applications of machining programming, simulation, and supervisory teams together.In summary, the CNC machining process digitalization helps to increase productivity, improve quality, and add competitive advantages to the manufacturers. However, this solution still is not received much interests because many manufacturers do not recognize these benefits. Its not easy for digitalizing all the entire manufacturing process, thus the enterprises should start from the critial stage as CNC maching as soon as better if they want to set their value in the global supply chain.

For more information, please contact:

Phone/Viber/Zalo/Whatsapp: 091929 5520

Email: [email protected]

Webisite: www.vietbay.com.vn * www.cadcamcae.vn * www.vietbay.edu.vn