In the context of the increasingly intense global competition, businesses are required to continuously change and improve their products to meet the ever-growing demands of the market. One of the key factors that need improvement is the performance, durability, and safety of the products. Below is how Haulotte, a company specializing in lifting equipment, improved the performance of its equipment by 50% using the Simcenter simulation and calculation software.

Challenges in Designing and Operating Lifting Equipment

Take a look at any construction site and you’ll see lots of scissor lifts being used for a variety of tasks. From indoor paint jobs to outdoor renovations, this type of construction lift with its elevating platform needs to perform well in a variety of challenging conditions.

Outdoor projects can be especially hard on this type of equipment. The ground can be muddy, uneven and tough to navigate. Muddy steep slopes require good traction perfor- mance to get the job done. Another key driver is noise and emission regu- lations. Lifts may not emit exhaust and can’t exceed certain decibel levels for operator and overall crew safety, especially indoors. This means engineers need to reduce the overall noise generated by the engine and the actua- tion systems as well as meet the ever-stricter standards applied to internal combustion engines (ICEs). As more urban areas adopt low-emission zones, manufacturers are being forced to accelerate innovation and produce alternative-energy equipment. In many cases, electric is the most viable way to go.

Finally, safety is paramount when it comes to construction equipment and lifts in general. These machines operate at heights above the ground, which means stability is the highest priority for both manufacturers and end users.

Simcenter Solutions – The Key to Optimizing Performance and Safety

Haulotte, one of the world’s leading manufacturers and sup- pliers of lifting equipment based in Lorette, France, has developed Pulseo, a range of next-generation, all-terrain electric scissor lifts. Suitable for both indoor and outdoor work, the all-electric Pulseo platforms offer superior performance compared to previous combustion engine models.

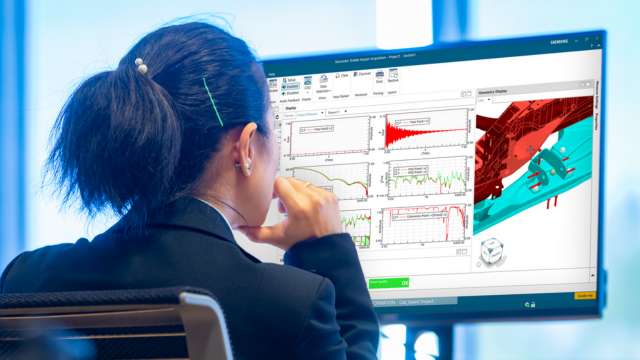

To develop these new models, Arnaud Chaigne, head of the simulation and digital validation division at Haulotte, and his team of engineers used simulation to study design possibilities and predict machine performance.

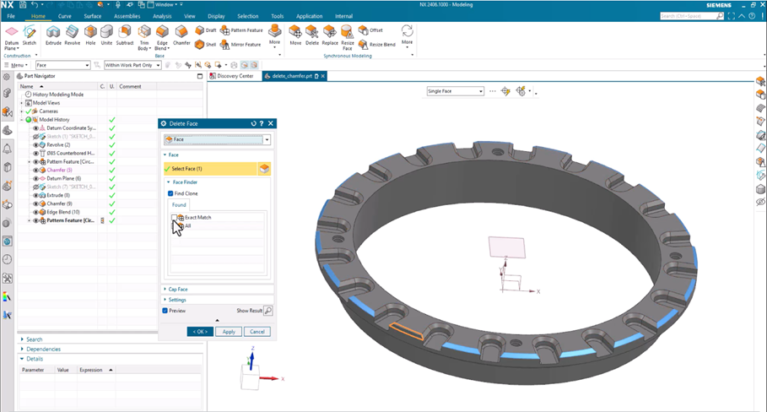

Haulotte uses Simcenter™ software tools for system and mechanical simulation. Simcenter is part of the Siemens Xcelerator business platform of software, hardware and services. Using these simulation tools, the engineers at Haulotte developed a line of market-ready, 12-kilowatt (kW) electric motor scissor lifts. The new lifts delivered better performance compared to the previ- ous model, which featured a 23kW internal combustion engine (ICE). Not only are the new electric scissor lifts pollution-free and quiet, but they also deliver better overall per- formance, including a maximum working drive height of 15 meters (m) instead of 12m and a load capacity of 750 kilograms (kg) instead of 500kg.

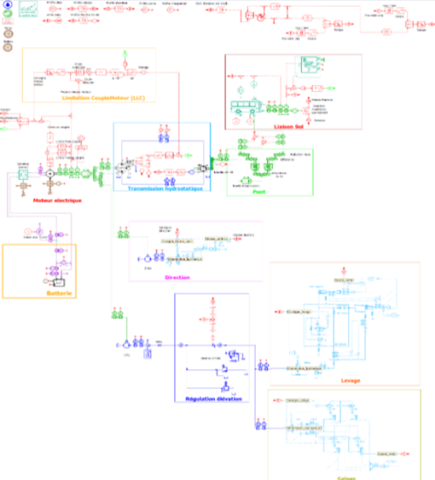

To determine the optimal architecture for future all-terrain Pulseo scissor lifts, Chaigne used Simcenter Amesim™ software for sys- tem simulation. One of the toughest parts of the task was optimizing the electric motor performance. Unlike conventional ICEs, to obtain the required power from the electric motor the team had to deal with many more design issues and constraints. To start, Chaigne identified the energy losses on all levels: from the engine throughout the entire structure, including hydraulic distribution

.

.

Broad Applications of Simcenter in Various Industries

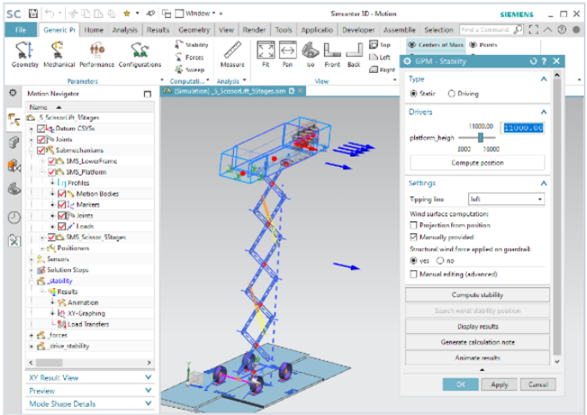

Regulations in various countries stipulate ele- vating lifts must remain stable, whether they are moving into position on a job site or standing still; for example, with the operator or workers on the platform. To be able to anticipate all possible scenarios, Chaigne and his team used Simcenter 3D Motion software to study the dynamic behav- ior of the scissor lift.

When working on the electric Pulseo series, the engineering team co-simulates Simcenter 3D models used for structure and stability analysis with Simcenter Amesim system sim- ulation models used for energy analysis and battery sizing.

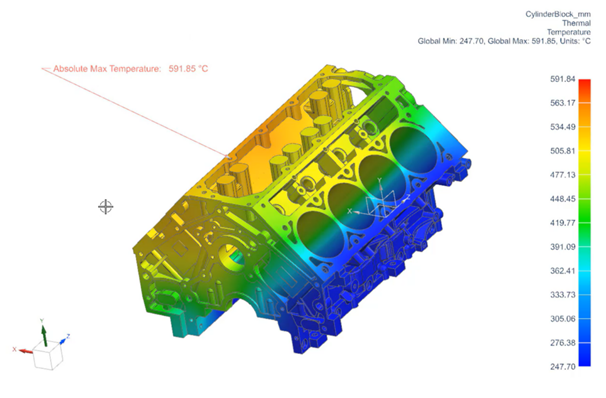

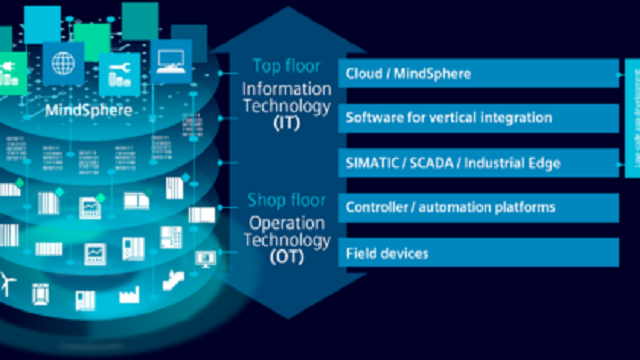

In addition, Simcenter offers various solutions applicable in different fields such as structural analysis, aerodynamics, thermal analysis, and multi-physics simulations. It is used in many industries, including aerospace, automotive, shipbuilding, and more.

Read more:

- New in Solid Edge 2024: Increase simulation speed, performance and reliability

- Comparing FlexSim and Siemens Plant Simulation: The Ultimate Production Simulation Tools for Performance and Efficiency

- Extending Simcenter Prescan’s sensor quality for real-world scenarios simulation

Contact us for free and detailed advice: