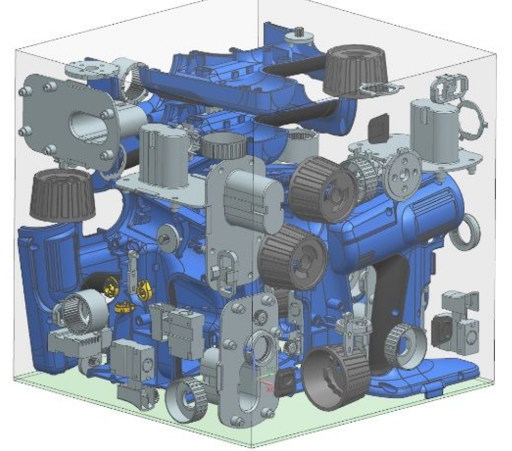

Automatically create various support structure types for use with powder bed printers using the new NX AM Fixed Plane Basic module

This new module, which is powered by Materialise, includes facilities for creation of support structures as well as for the setup of the build tray, positioning and patterning of parts in the build tray, and a build processor framework for connection to powder bed printers.

HP Multi Jet Fusion Printers

The landscape for printing plastic is evolving as new vendors are entering the industry. One exciting new addition to the hardware landscape for plastic printers is HP with their Multi Jet Fusion technology.

NX 12 has a new module, certified by HP and powered by Materialise, enabling customers to design, optimize, simulate, prepare print jobs, and inspect processes for HP Multi Jet Fusion 3D printers. NX users can load multiple models, auto nest the models in 3D, and submit the job to HP 3D printers in a single NX environment and with a minimum number of steps.

When HP’s new 3D printers are combined with the power of Siemens NX, printing of plastic parts is easier, faster, and more accurate than ever before

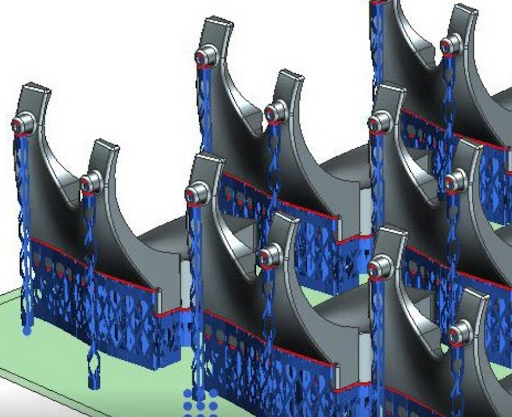

Companies are looking to innovative solutions in the constant drive to reduce component weight and improve resource usage. Lattice structures are one way designers can meet these goals without compromising on strength and structural integrity. NX 12 delivers on these new approaches to design for additive manufacturing with the integrated ability to create lattice structures, powered by Materialise.

This new module allows users to create regular lattice structures as well as randomized structures within a volume. When combined with Convergent Modeling Technology™, which makes it possible to work directly with facet geometry, creating cutting-edge structures like these is easier than ever before. Furthermore, having these capabilities in a single system saves companies from the hidden data conversion costs normally required to work with such geometry.

With lattice structures and Convergent Modeling TechnologyTM in NX 12, companies can deliver lighter, stronger products to market in much less time, fulfilling the need for cutting-edge design of lightweight parts.