The digital trend has been affecting global production. Manufacturers are looking for solutions that can fully digitize stages in the design and production process in order to improve quality and increase productivity, shorten time to market to increase global competitiveness. For industrial machinery and automation industries, the requirements are increasingly such as high complexity, and flexibility, individualized products, energy efficiency, intelligent integration and compatibility with other systems. In addition, demand for IIot connectivity, remote monitoring or even remote maintenance has been significantly increasing.

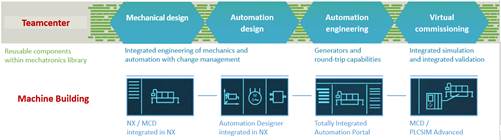

To meet the digital trends and requirements, it is required businesses constantly improve and apply new technologies. One of the technology solutions that industrial machinery and automation enterprises are stepping up to is to build a Digital Twin of machines for simulation before and in parallel with physical machines combined with virtual reality technology (VR), augmented reality (AR), 3D printing technology. The picture below describes further about the solution to build a Digital Twin of industrial machines and automation machines.

Vietbay provided solutions allow the design, modeling and digitization of all related components of industrial machines, automation machines including mechanical parts, electronic parts, electrical parts, automation and transmission, sensors, control signals. In addition, the solutions enable connection to a virtual PLC controller or a real PLC to operate the machine’s virtual environment. Users are able to emulate the control screens or control switches of the machine. The machine then performs control via PLC programs such as that for the physical machine.

With synchronous integration on the same software platform, it allows design teams such as mechanical groups, electrical automation groups, and electronics groups to participate in at the same time and interact to deliver the most optimal product while simultaneously shortening the design and development time of the product.

The solutions also integrate product data management software to manage documents, processes, BOM, change management, requirement management, supply chain management etc. on a single unified platform with collaboration to minimize errors, increase reuse, and enhance work on digital platforms. Processes and documentation are standardized and digitized.

Furthermore, industrial machinery and automation machinery manufacturers are able to expand design tool such as generative design, structural dynamics simulation, and additive manufacturing, combining simulation and virtual reality to review machine performance with a more intuitive sense.

The special and optimal feature of the solution is the synchronous integration on a single platform that reduces data conversion time, data version errors, enhances reuse, and teamwork, easily manage data, manage changes and requirements.

Vietbay CAD/CAM/CAE/PLM Team

Phone/Zalo/Whatsapp: 091 929 5520

Email: [email protected]

Website: www.vietbay.com.vn * www.cadcamcae.vn * www.vietbay.edu.vn