NX Mold Connect addresses challenges in the tooling industry

One of their biggest challenge as per the business development lead at this company, is streamlining the bidding process that’ll help them with competitiveness. Based on tooling industry reports and survey, tooling companies win less than 50% of the jobs they quote and, in many cases, even less. A significant amount of effort goes into creating an accurate quote. Like many tooling companies, this company also relied on manual processes in generation quotes that may not be accurate due to errors in cost and lead time estimation. According to a survey of 370 mold-makers conducted by Tech-Clarity, an independent research firm, respondents report that on average, molds cost 27% more than they estimated during bidding, and it takes 28% longer to deliver it than they expected when they bid for the job.

Another challenge that mold-makers face is collaboration during the tool design phase. Data from the same survey shows that poor communication can add 26% to the cost of the tool. As per the Tech-Clarity eBook based on the survey results ‘Breaking the Mold’, these costs can come from many places. For example, consider a change that is not adequately communicated, and major design work is based on outdated information, or maybe the wrong size steel is ordered, or perhaps the wrong version of a drawing is released to manufacturing. All of this can result in scrap and rework that adds to the mold cost.

To address these two key challenges of streamlining the bidding process and enhancing collaboration between the stakeholders, the team at Siemens has been developing a browser-based app to modernize the injection mold development workflow. We would like to introduce you to NX Mold Connect.

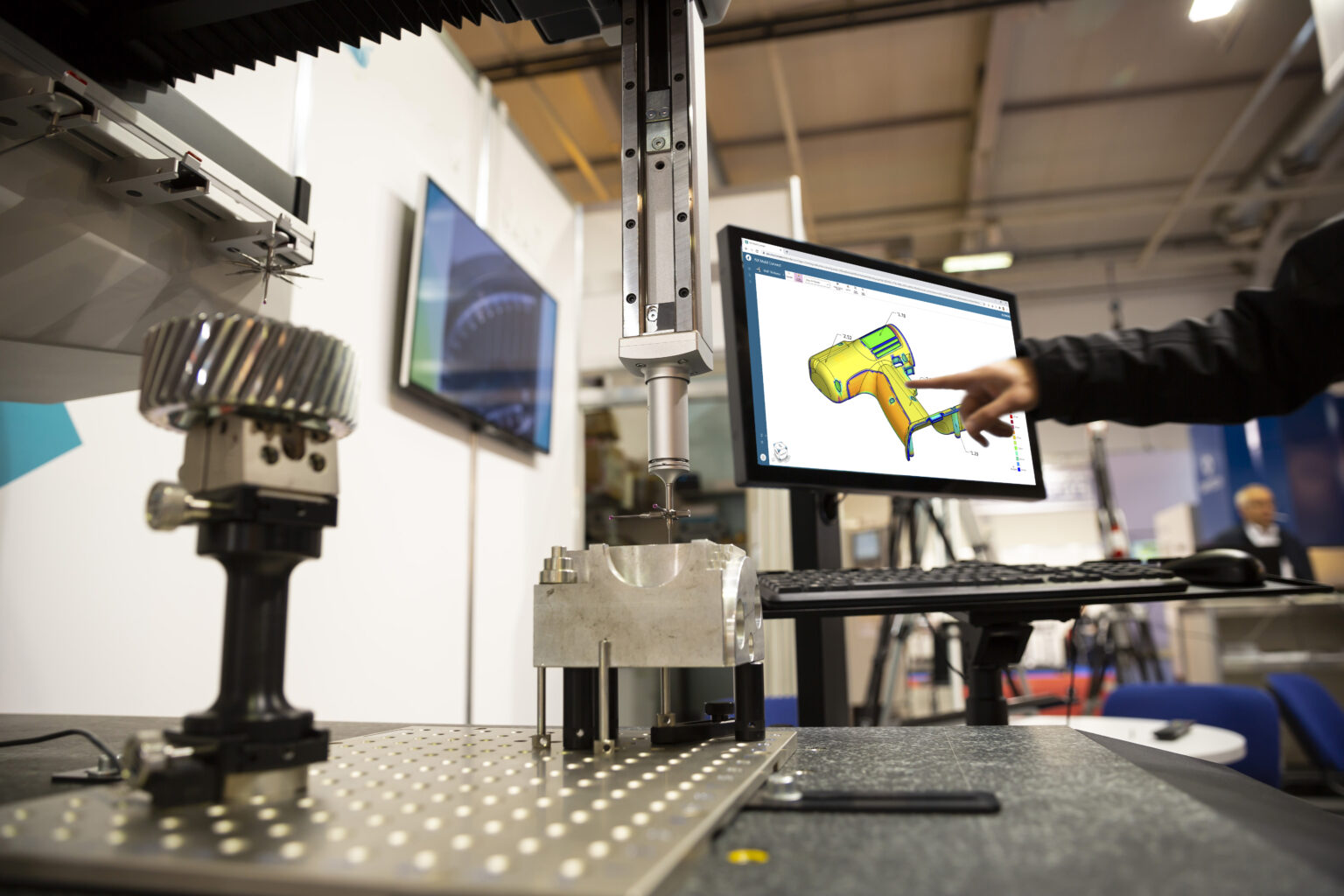

Try our new browser-based app: NX Mold Connect

NX Mold Connect provides a faster, easier way to collaborate on injection molded parts. The browser-based app lets part designers and tool shops:

● examine the 3D geometry, add mark-ups and share over a secure, cloud-based hub

● perform Design for Manufacturability checks to ensure part quality

● speed-up the RFQ process with automated feature recognition for cost estimation

Register today!

For more information, please contact:

Vietbay CAD/CAM/CAE/PLM Team

Phone/Zalo/Whatsapp: 091 929 5520

Email: [email protected]

Website: www.vietbay.com.vn * www.cadcamcae.vn * www.vietbay.edu.vn