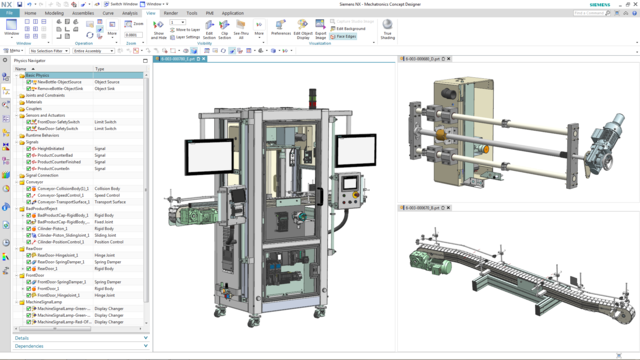

Mechatronic Concept Design is made up of powerful features that allow you to build a custom solution. Read more about these features below.

You can trace customer requirements all the way through to a finished design using systems engineering principles. A functional model provides a common language for mechanical, electrical and automation disciplines to work together in parallel, which helps you deliver designs faster and with fewer integration issues late in your design process

Open Interfaces to Other Tools

Open Interfaces to Other ToolsThe output of Mechatronics Concept Designer can be used directly by multiple disciplines to continue to refine the designs without the need to re-master the data.

- Mechanical designers can use concept models in NX for detailed design

- Electrical designers can use model data to select sensors and actuators

- Automation designers can use cams and operation sequence information from the model for software development

Physics-Based Simulation Capability

Mechatronics Concept Designer has easy-to-use modeling and simulation which allows you to quickly create and validate alternative design concepts early in the development cycle. Unlike a model based tool, MCD allows you not only to see what it looks like, but validate that it works. While model centric tools show you the geometry and allow you to model the parts, we go further and allow you to validate that your product works before you build it. This validation is enabled by the re-use library, from which you can quickly add data to the functional model. This data includes joints, motion, sensors, actuators, collision behavior, and other kinematic and dynamic properties for each component. This allows a physics-based, interactive simulation to verify machine operation. This verification helps you detect and correct errors in the digital model.

Virtual commissioning

- Simulate the real machine behavior,including programmable logic controller, (PLC), computer numerical control (CNC), actors and sensors

- Re-use your 3D concept model for visualization and CNC program simulation

- Validate your production parameters and test your PLC program

Benefit

- Seamless engineering from the idea (concept) up to commissioning

- Commissioning – the most capital-Intensive phase – slashed by up to 70% at the real machine

- Damage to the real machine is avoided

- First validation of the program for part production in a virtual environment, essentially under real conditions

Vietbay is the strategic partner of Siemens PLM – The leading industrial software company in the world with cooperating milestones of “Asia Pacific New Constructor’s Champion FY14”, The First Gold Partner in Vietnam in 2016, and Siemens Authorized Training Partner (STP) in 2017.

Our sales and technical experts are available for any inquiry of consulting technology and solutions of computer network design and administration, software assets optimization and integrated CAD-CAM-CAE, Data Management (PDM), Tool/Product Costing, Product Lifecycle Management (PLM), MES and other smart manufacturing with adoptable budget.For more details, please contact us: Vietbay CAD/CAM/CAE/PLM Team – “More Value with Trust”

Tel: 091 929 5521 (Sales) /091 929 5527 (Technical) * Email: [email protected] Website: www.vietbay.com.vn ; www.phanmembanquyen.com