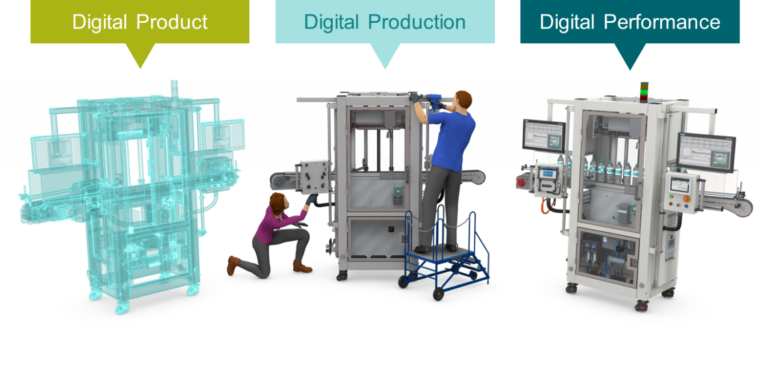

The Digital Twin is a new concept in the global digitalization trend. Depending on the goals and scope of the application, Digital Twins are built and applied in different ways.

For example, Digital Twin of the factory, Digital Twin of the production line, Digital Twin of machine tools… so what is Digital Twin?

Let Vietbay give you some detailed information!

What is Digital Twin?

In essence, the Digital Twin of a factory or machine tool is a digital model (a virtual model of a physical object) represented and described in a digital environment. It contains the same properties as the physical object, including:

- Geometric properties: expressed through shape, size, position, …

- Physical properties: material, temperature, …

- Control properties

- Process attributes

On the Digital Twin, all components that need to be considered are modeled.

Purpose of using Digital Twin

Depending on the field, Digital Twins are applied for many different purposes, but there are common goals among them, as follows:

Visualize objects (machines, production lines, factories)

Use for demonstration and description to customers, partners, internally between departments, or for operational training based on a virtual environment without performance in a physical environment. This is done for many different reasons, such as being safer, easier to copy, and being done anywhere, anytime.

Test operational scenarios

Test scenarios that work without a real machine or without affecting a real machine:

- Evaluate design errors (for example, collision with the station, over-travel, etc.).

- Evaluate operating errors.

- Evaluate process logic programming errors.

- Evaluate energy consumption.

- Evaluate the performance of the machine, the line, and the entire factory.

- From there, the most optimal operating scenario can be chosen.

Create a collaborative environment

Create a collaborative environment between technical teams such as the automation team, mechanical team, and electrical team from the concept design stage to shorten development time.

Benefits of Digital Twin

Visual review machines, lines, or the entire production plant in a virtual environment, allowing you to quickly test different operating scenarios even if there is no physical model or no influence on the manufacturing operations of the physical model. From there, users can make decisions to change, upgrade, improve, or simply choose the most optimal version to improve performance as well as save time and costs.

Improve safety

Improved safety: simulation testing in a virtual environment is faster and safer for machines, avoiding damage as well as saving energy and manpower because all operations are performed in the virtual environment.

Improve machine design, production lines, or factory layout

All operational scenarios are tested in advance, so technical teams can participate in parallel work right from the initial idea generation stage. This shortens design time, makes optimal decisions, minimizes repetition, and minimizes testing time in the physical environment.

It can be reviewed, evaluated, and demonstrated anytime, anywhere, without dependence on physical models or the need for transportation.

Tasks can be applied, guided, and trained even without a physical model to easily organize plans for new projects, which can simulate human tasks in manufacturing, ergonomic assessment, reach assessment, and safety assessment.

Solutions for building Digital Twin

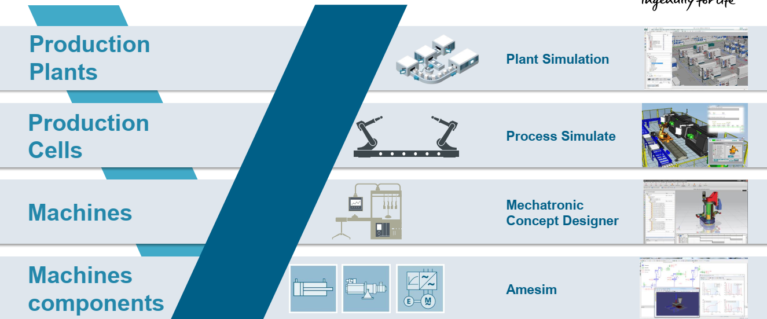

Vietbay is currently the distribution representative of leading industrial software companies in the world, such as Siemens, Cgtech, Cimco, Autodesk, etc. These software solutions serve the purposes of designing and building Digital Twins of products, industrial machines, production lines, or entire factories, for example:

- NX and Simcenter to build digital twins of products and industrial machines

- Tenomatix to build Digital Twins of production lines or factories

- Vericut to build a Digital Twin of CNC machines…

Learn more:

Solution to build Digital Twin of Automation Machines

Contact us for free and detailed advice